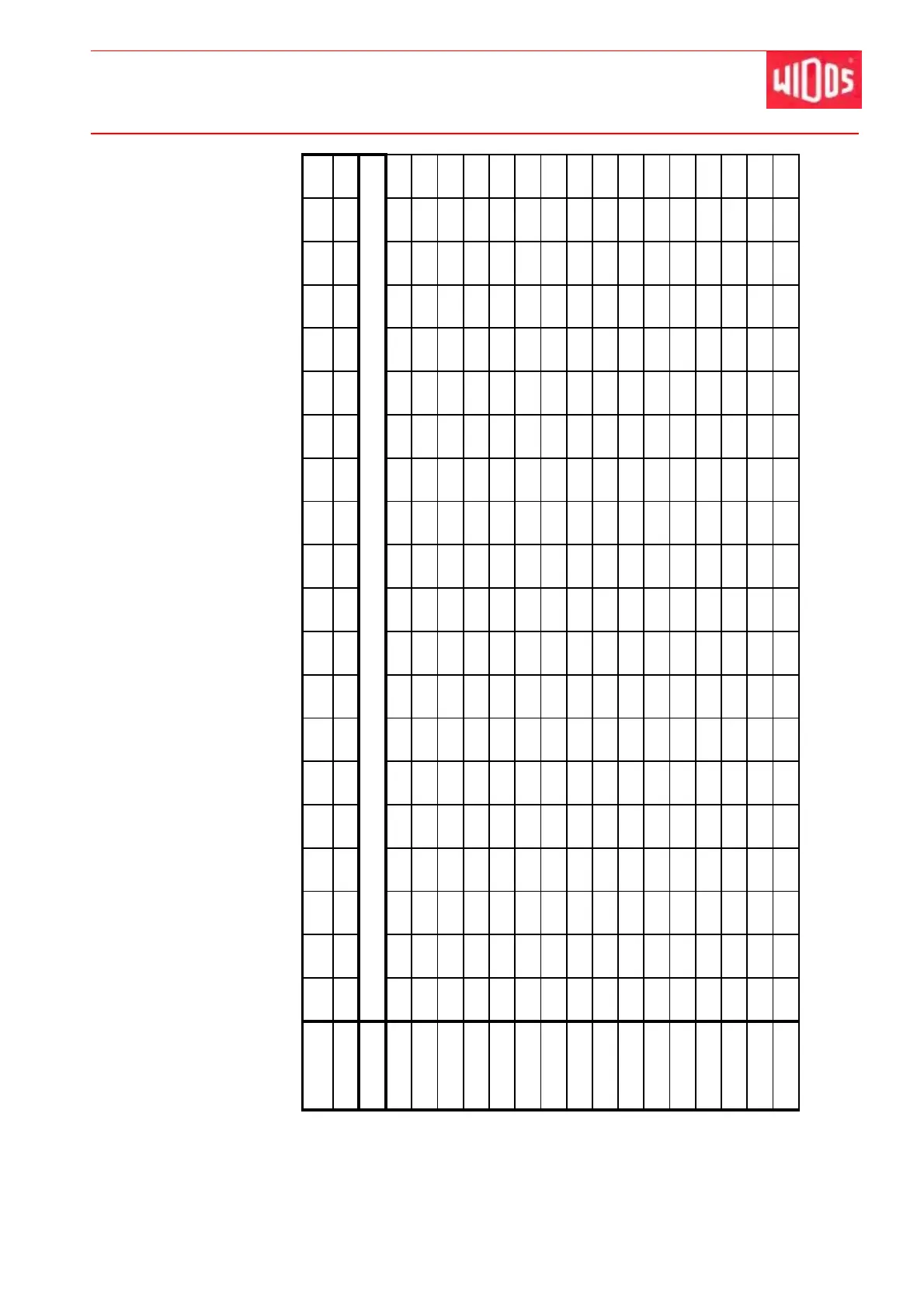

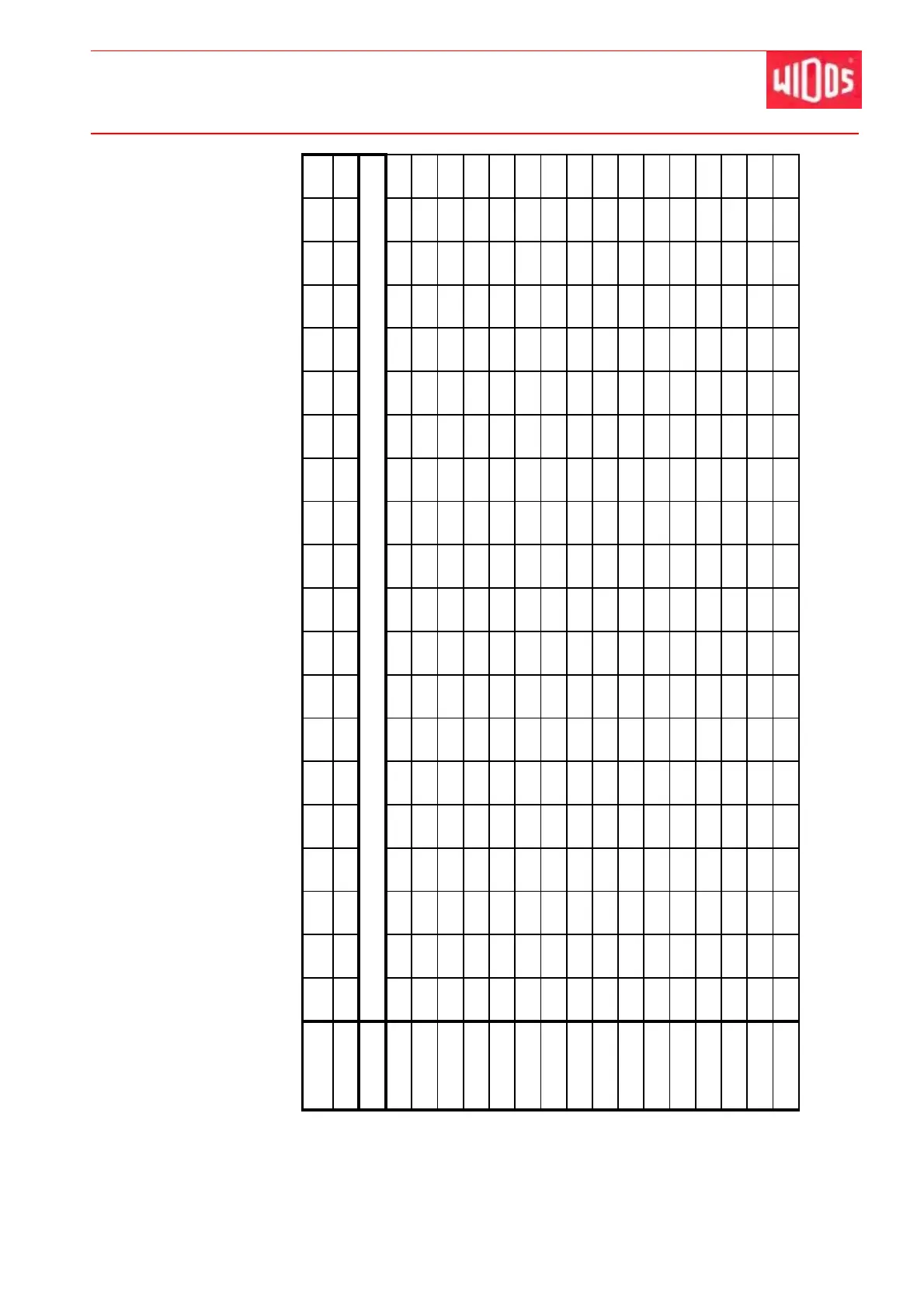

Kunststoffschweißtechnik

Welding Table Chapter 6

20

2

14

16

19

21

24

27

29

32

34

37

40

42

45

47

50

53

19

2

13

15

18

20

23

25

28

30

33

35

38

40

43

45

48

50

18

2

12

15

17

19

22

24

26

29

31

33

36

38

40

43

45

47

17

2

12

14

16

18

20

23

25

27

29

32

34

36

38

40

43

45

16

2

11

13

15

17

19

21

23

26

28

30

32

34

36

38

40

42

15

2

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

14

2

10

11

13

15

17

19

21

22

24

26

28

30

32

33

35

37

13

2

9

11

12

14

16

17

19

21

23

24

26

28

29

31

33

34

12

1,5

8

10

11

13

15

16

18

19

21

22

24

26

27

29

30

32

11

1,5

8

9

11

12

13

15

16

18

19

21

22

23

25

26

28

29

10

1,5

7

8

10

11

12

14

15

16

17

19

20

21

23

24

25

27

9

1,5

6

8

9

10

11

12

13

15

16

17

18

19

20

22

23

24

8

1,5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

7

1,5

5

6

7

8

9

10

11

11

12

13

14

15

16

17

18

19

6

1

4

5

6

7

8

8

9

10

11

11

12

13

14

15

15

16

5

1

4

4

5

6

6

7

8

8

9

10

10

11

12

12

13

14

4

1

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

3

0,5

2

3

3

4

4

4

5

5

6

6

6

7

7

8

8

8

2

0,5

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

23

1

0,5

1

1

1

2

2

2

2

2

2

2

2

3

3

3

3

3

PE 80

PE 100

1 kp =

Tickness

Bead height

Lenght

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

Table for PE

Heating up time = 10 x wall thickness [sec]

Cooling down time under joining pressure = 1,333 * wall thickness [min]

The standard value for the heating element temperature is between 200° C - 220° C.

J o i n i n g p r e s s u r e

[bar]

For

smaller

wall thickness higher temperatures should be relized.

The standard value for the heating element temperature is 220° C.

The change-over and pressure building up time should be realized with PE 100 as fast as possible!

N; For the given adjusting and welding pressure the movement pressure of the welding slide has to be added!

10.12.2013 Working Instructions WIDOS PSM 20 page 24 / 1 of 31

Loading...

Loading...