EN

27WIKA operating instructions, models TRxx and TCxx

14150915.08 04/2024 EN/DE/FR/ES

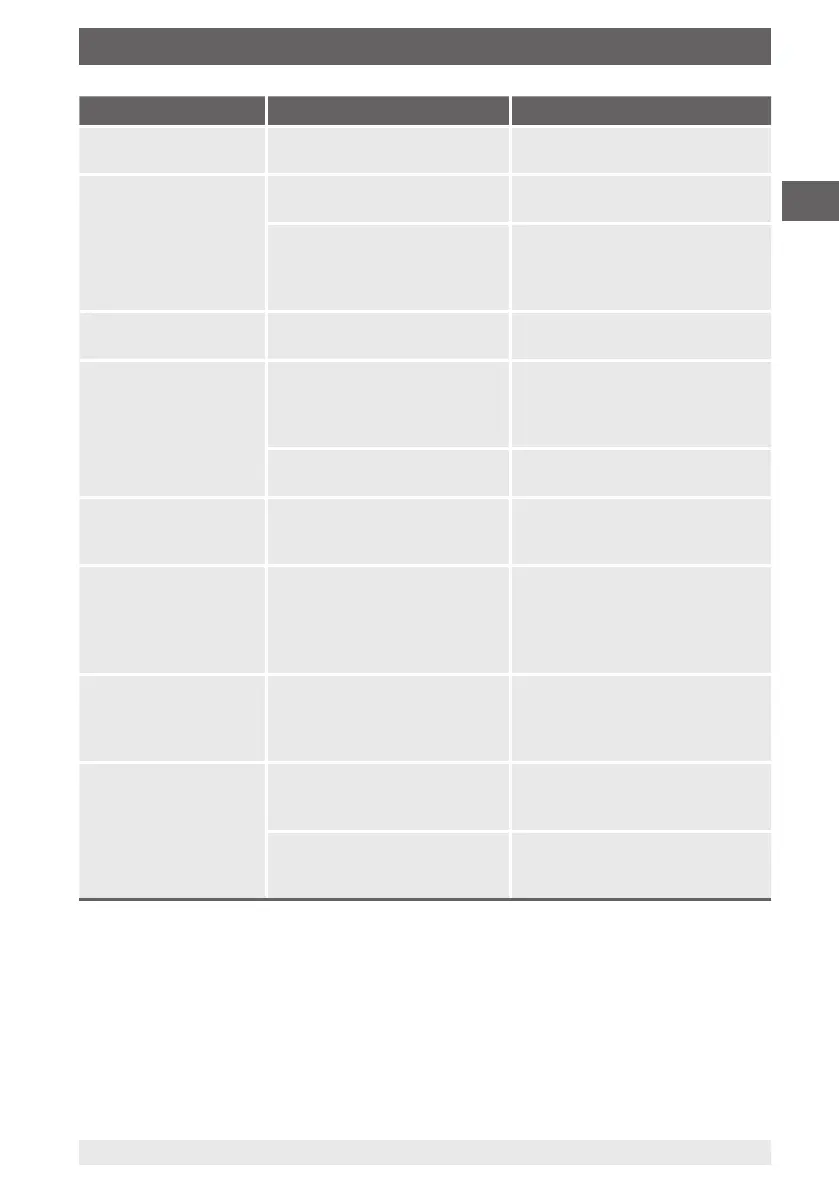

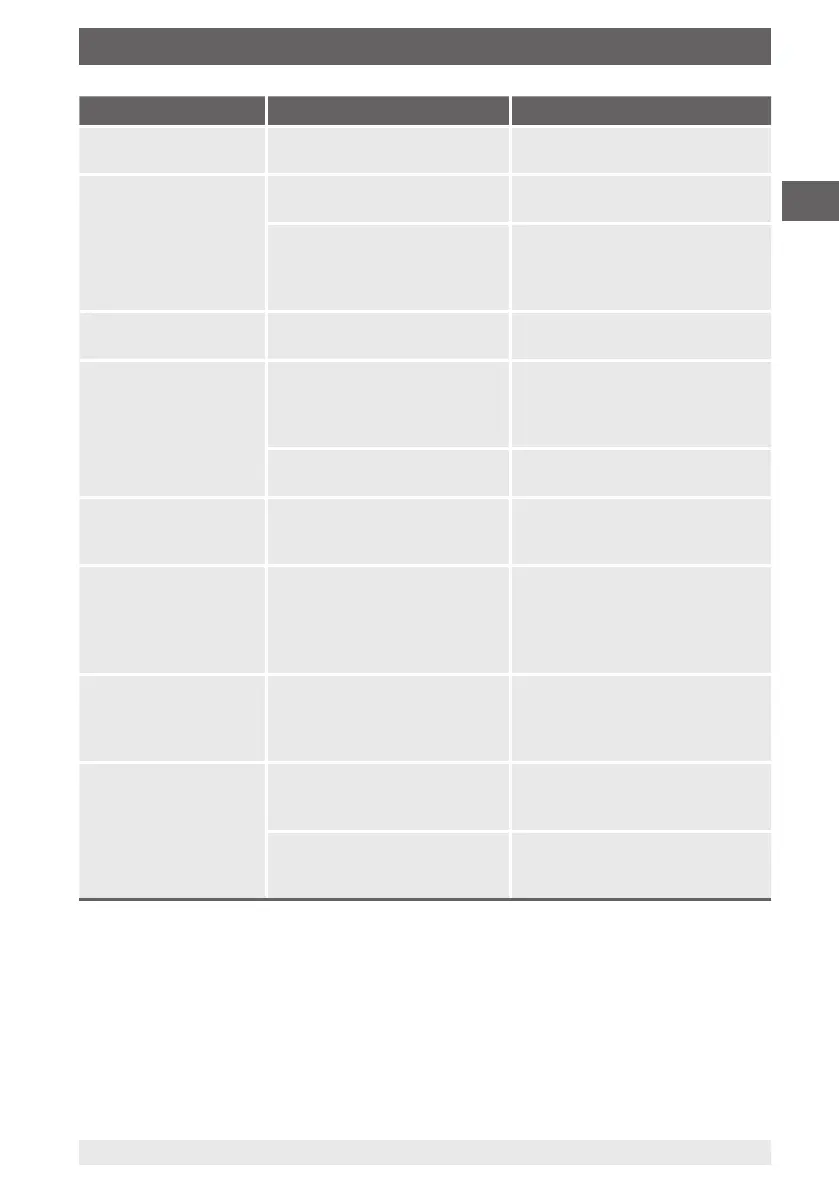

Faults Causes Measures

No signal/cable break Mechanical load too high or

overtemperature

Replace probe or measuring insert

with one of a suitable design

Erroneous measured

values

Sensor drift caused by

overtemperature

Replace probe or measuring insert

with one of a suitable design

Sensor drift caused by chemical

attack

■

Analyse the medium

■

Select a more suitable material

or replace thermowell/protec-

tion tube regularly

Erroneous measured

values (too low)

Entry of moisture into cable or

measuring insert

Replace probe or measuring insert

with one of a suitable design

Erroneous measured

values and response

times too long

Wrong mounting geometry, e.g.

insertion depth too small or heat

dissipation too high

The temperature-sensitive area

of the sensor must be inside the

medium, and surface measure-

ments must be ungrounded

Deposits on the sensor or

thermowell/protection tube

Remove deposits

Erroneous measured

values (of thermocou-

ples)

Parasitic voltages (thermoelec-

tric voltages, galvanic voltage)

or wrong compensating cable

Use suitable compensating cable

Display of measured

value jumps

Cable break in connection cable

or loose contact caused by

mechanical overload

Replace probe or measuring insert

with a suitable design, for example

equipped with a bend protection

spring or a thicker conductor

cross-section

Corrosion Composition of the medium not

as expected, modified or wrong

thermowell/protection tube

material selected

■

Analyse the medium

■

Select a more suitable material

or replace thermowell/protec-

tion tube regularly

Signal interference Stray currents caused by

electric fields or ground loops

Use shielded connection leads,

and increase the distance from

motors and power cables

Ground loops Eliminate potential differences by

using galvanically isolated repeat-

er power supplies or transmitters

6. Faults

Loading...

Loading...