14

INSTALLING

YOUR FURNACE

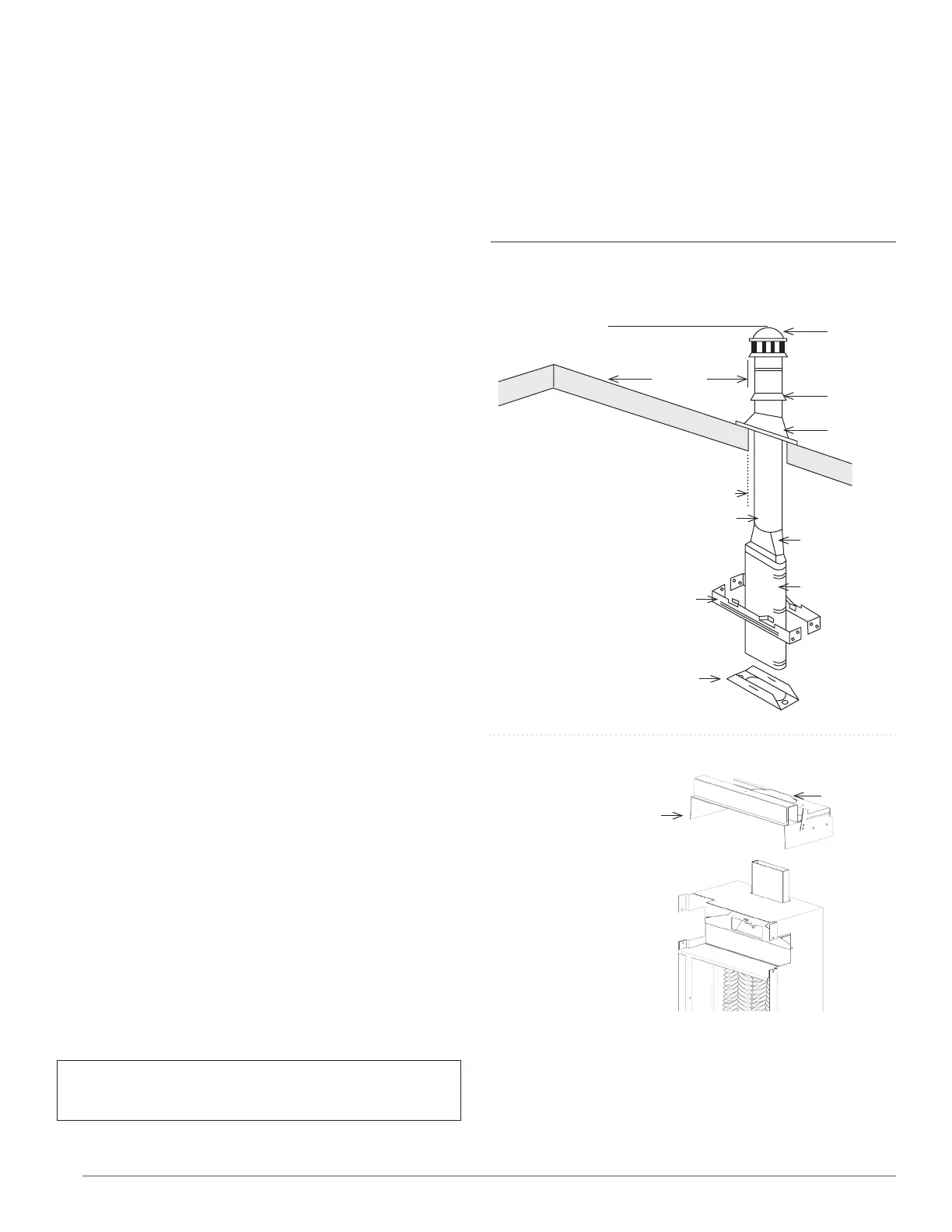

Vent Installation

The vent installation must comply with all local codes and

ordinances. If in doubt, consult your local codes or inspector.

The furnace vent must be directed to the outdoors so that

harmful combustion gases will not collect inside the building.

This furnace must not be connected to a chimney flue

serving a separate solid-fuel burning appliance.

This product is design certified to ANSI Z21.86. It must be

installed with a U.L. tested and listed type “B” approved vent

and type “B/W” approved vent (Figure 8). Older style terra-cotta,

transite, clay, concrete or masonry type vent pipe cannot be

used with this appliance. These types of vent pipe will not heat

fast enough to establish a draft, which will result in improper

venting of combustion products. Consequently, this could

cause the vent safety control system to shut down the furnace.

The area above header within the stud space MUST be kept

clear of any attic insulation to allow the free circulation of air

around the oval vent piping. In some areas the building code

requires the use of an attic shield.

The B/W vent must extend through the ceiling and roof

terminating at least 12-feet above the finished floor on

which the furnace rests.

Install Furnace vent

Attach a 4-foot length of oval, double-wall vent pipe through

the plate spacers to the hold-down plate. Push the vent pipe

into the hold-down plate until it is completely seated. The

hold-down cleat will engage the groove in the vent pipe.

Complete the venting

Type B/W gas vent shall extend from the header plate of the

furnace to a point above the highest ceiling plate within the

stud space through which the vent passes, without any offsets

or crossovers. The first vent pipe offset, (if required), may not be

any closer than 2-feet from the header and needs to extend

past the ceiling plate. After a type B/W gas vent passes through

the highest ceiling plate within a stud space above the furnace

to which it serves, the vent system may be completed with a

Type B gas vent, from the SAME manufacturer (do not mix

brands of pipe). Offsets cannot be greater than 45 degrees

from vertical. Refer to The Uniform Mechanical Code.

Install the oval-to-round adapter. Complete the piping

extending it through the roof. Use a 4-inch round, double-

wall (Type B) vent pipe, roof flashing, storm collar and vent

cap as shown. The vent cap must be at least 2-feet higher

than any point that is within 10- feet of the vent cap. There

must be at least a 1-inch clearance between the vent pipe

and any combustible material.

CAUTION: To avoid damage to wiring, be sure to route the

wires away from the path of the furnace vent.

FIGURE 8 – Typical Vent Installation

VENT CAP MUST BE MINIMUM 2 FEET

HIGHER THAN ANY POINT WITHIN

10 FEET OF THE VENT CAP

10 FEET

LISTED

VENT CAP

STORM

COLLAR

ROOF

FLASHING

HEIGHT FROM HEADER PLATE

TO THE VENT CAP TOP MUST

BE 6 FEET MINIMUM

1 INCH MIN. CLEARANCE TO COMBUSTIBLES

LISTED 4 ROUND B VENT

OVAL TO ROUND

ADAPTER

OVAL BW VENT

DOUBLE WALL

PLATE SPACER

RECESSED MOUNT

2 REQUIRED

BASE PLATE HOLD DOWN

OR STARTER PLATE SCREWED

DOWN TO HEADER PLATE

50,000 BTUHR. MODEL SERIES

AND HEADER NOT SHOWN

NOTE: THESE PARTS ARE

SUPPLIED WITH THE FURNACE

HEADER PLATE AND GASKETS

PROVIDED WITH FURNACE

GASKET

Loading...

Loading...