10

English

2.6 Safety instructions for installation and main-

tenance work

The operator must ensure that all installation

and maintenance work is carried out by authori-

sed and qualied personnel who are sufciently

informed from their own detailed study of the

operating instructions.

Work on the product/unit must only be carried out

when at a standstill. It is mandatory that the pro-

cedure described in the installation and operating

instructions for shutting down the product/unit

be complied with.

Immediately on conclusion of the work, all safety

and protective devices must be put back in posi-

tion and/or recommissioned.

2.7 Unauthorised modication and manufacture of

spare parts

Unauthorised modication and manufacture of

spare parts will impair the safety of the product/

personnel and will make void the manufacturer’s

declarations regarding safety.

Modications to the product are only permissible

after consultation with the manufacturer. Original

spare parts and accessories authorised by the

manufacturer ensure safety. The use of other

parts will absolve us of liability for consequential

events.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accor-

dance with Section 4 of the operating instruc-

tions. The limit values must on no account fall

under or exceed those specied in the catalogue/

data sheet.

3. Transport and interim storage

When receiving the material, check that there

has been no damage during transport. If shipping

damage has occurred, take all necessary steps

with the carrier within the allowed time.

CAUTION! Outside inuences may cause dama-

ges.

If the delivered material is to be installed later on,

store it in a dry place and protect it from impacts

and any outside inuences (humidity, frost etc.).

Handle the pump carefully so as not to alter the

geometry and the alignment of the hydraulic unit.

Never lift the pump at its power cable.

4. Product and accessories

4.1 Application

The pump has been designed to pump clear water

or slightly contaminated water in residential, agri-

cultural and industrial applications or for pumping

water from wells, springs, rivers or ponds.

• Irigation

• Sprinkling

4.2 Description (Fig. 1)

1 - Foot valve with strainer

(maximum opening width 1 mm)

2 - Pump suction valve

3 - Pump discharge valve

4 - Filling plug

5 - Drain plug

6 - Pipe support

HA - Suction head

4.3 The pump

• Centrifugal, horizontal, single-stage

• Self-priming

• Tapped ports, axial suction shifted upwards,

radial delivery towards above. Sealed shaft with a

mechanical seal.

4.4 The motor

Single-phase: Dry motor, two poles.

Capacitor in terminal box.

Thermal protection with automatic reset (single-

phase version).

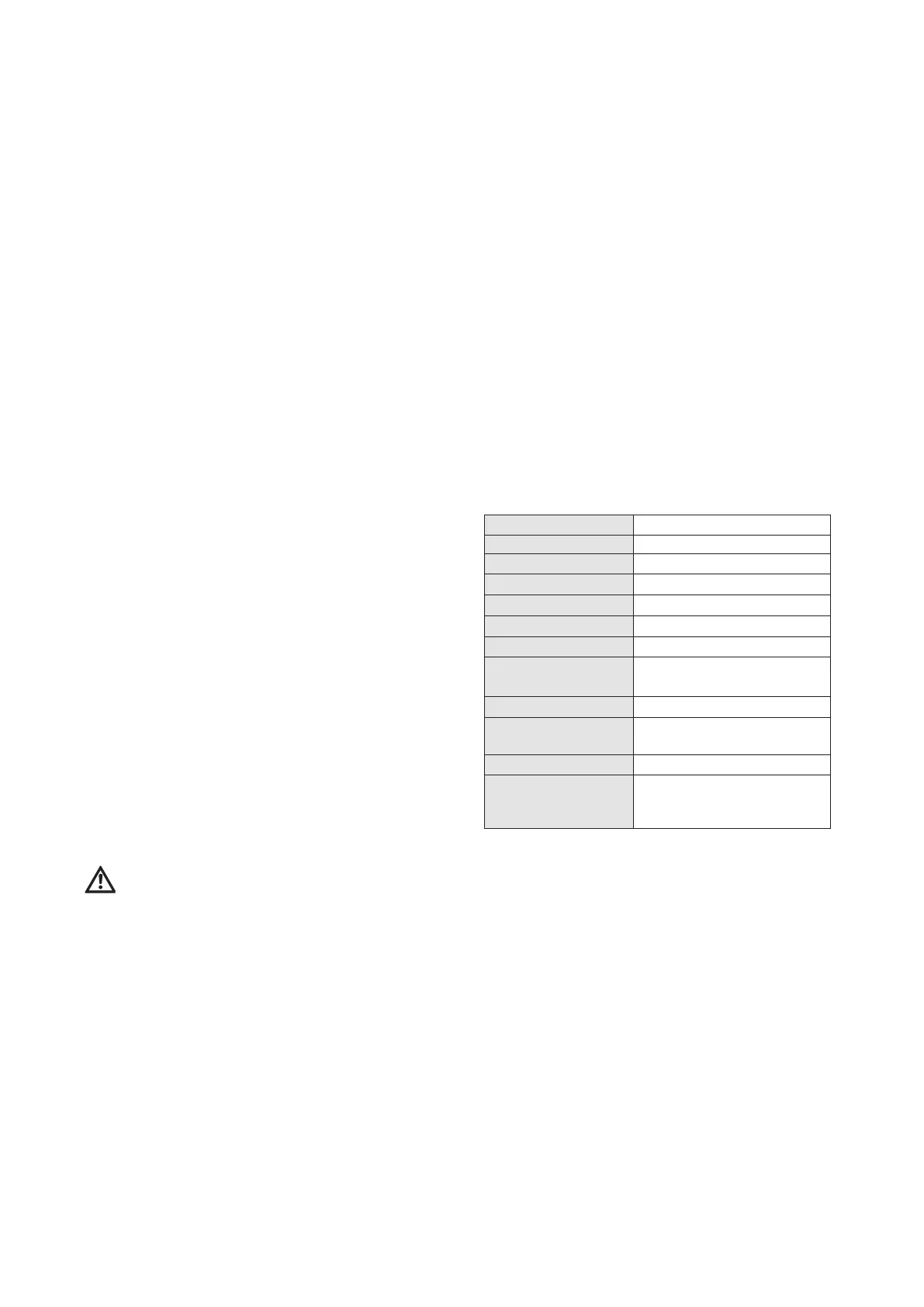

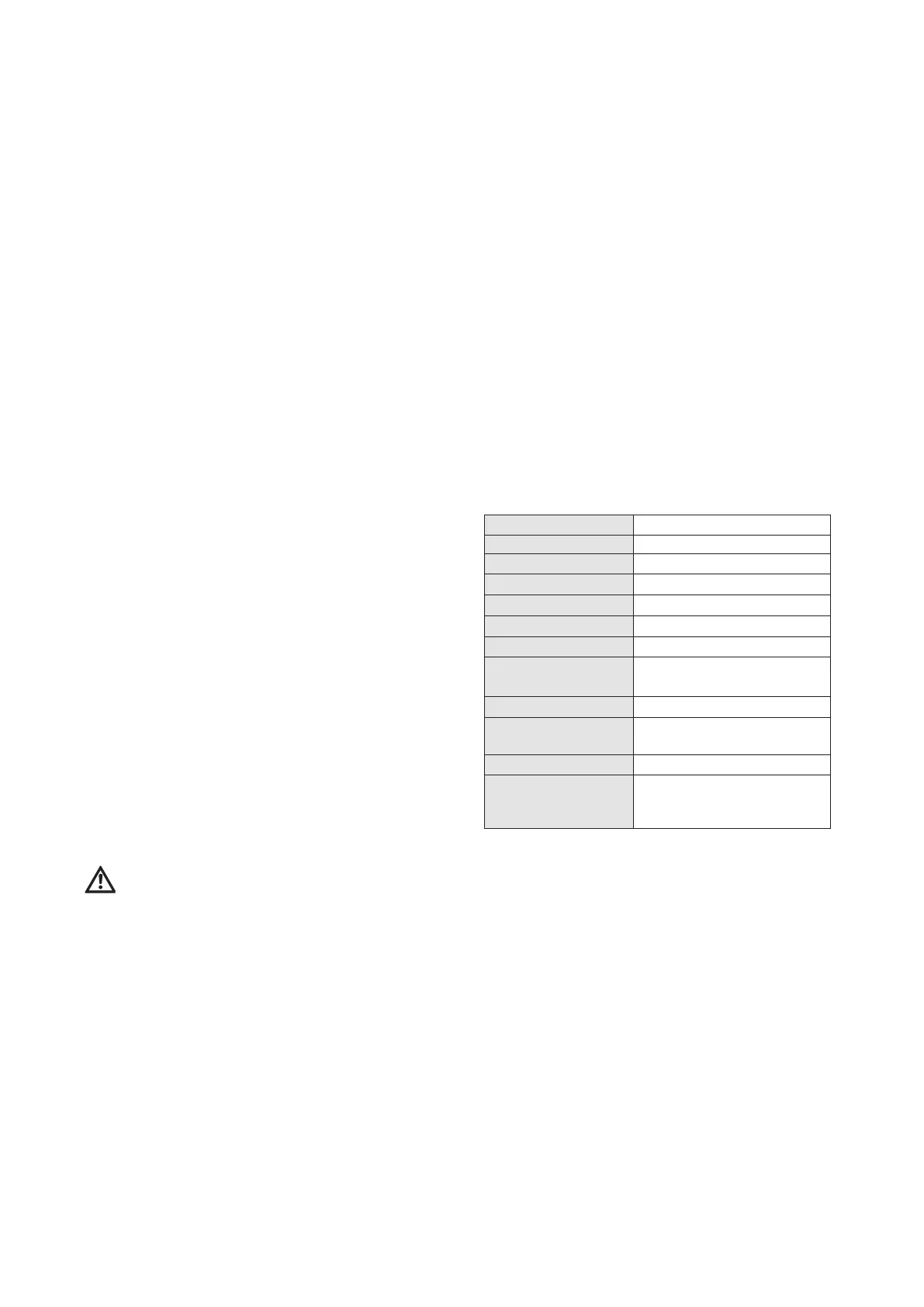

Technical data

4.5 Accessories (optional)

The use of new accessories is recommended.

Protection control and automatic management,

suction kit, isolating valves, non-return valves,

foot valve with strainer, diaphragm pressure ves-

sel, vibrationless sleeves, dry-running protection,

on/off control device.

5. Installation and electrical connection

5.1 Installation

Install the pump in an easily accessible place,

protected from frost, and as close as possible to

the place from which water is drawn.

Install the pump on a foundation block or directly

on a smooth, level oor.

Attach the pump using the two notches on the

spacer-support (8-mm bolting).

Mains voltage 1~230 V, ± 10 %

Mains frequency 50 Hz

Protection class IP44

Insulation class 155

Speed 2 900 rpm (50 Hz)

Max. delivery head See name plate

Max. ow rate See name plate

Min. / Max. suction

pressure

0.08 to 0.2 Mpa (- 0.8 to 2 bars)

Temperature range + 5 to 35 °C

Max. ambient

temperature

+ 40 °C

Max. suction head 7 m

Connection suction/

delivery side

G1“ (3-4 / 4-4)

G1

1/4

“ (9-4)

WILO SE 02/2018

Loading...

Loading...