en Maintenance and repair

84 WILO SE 2019-10

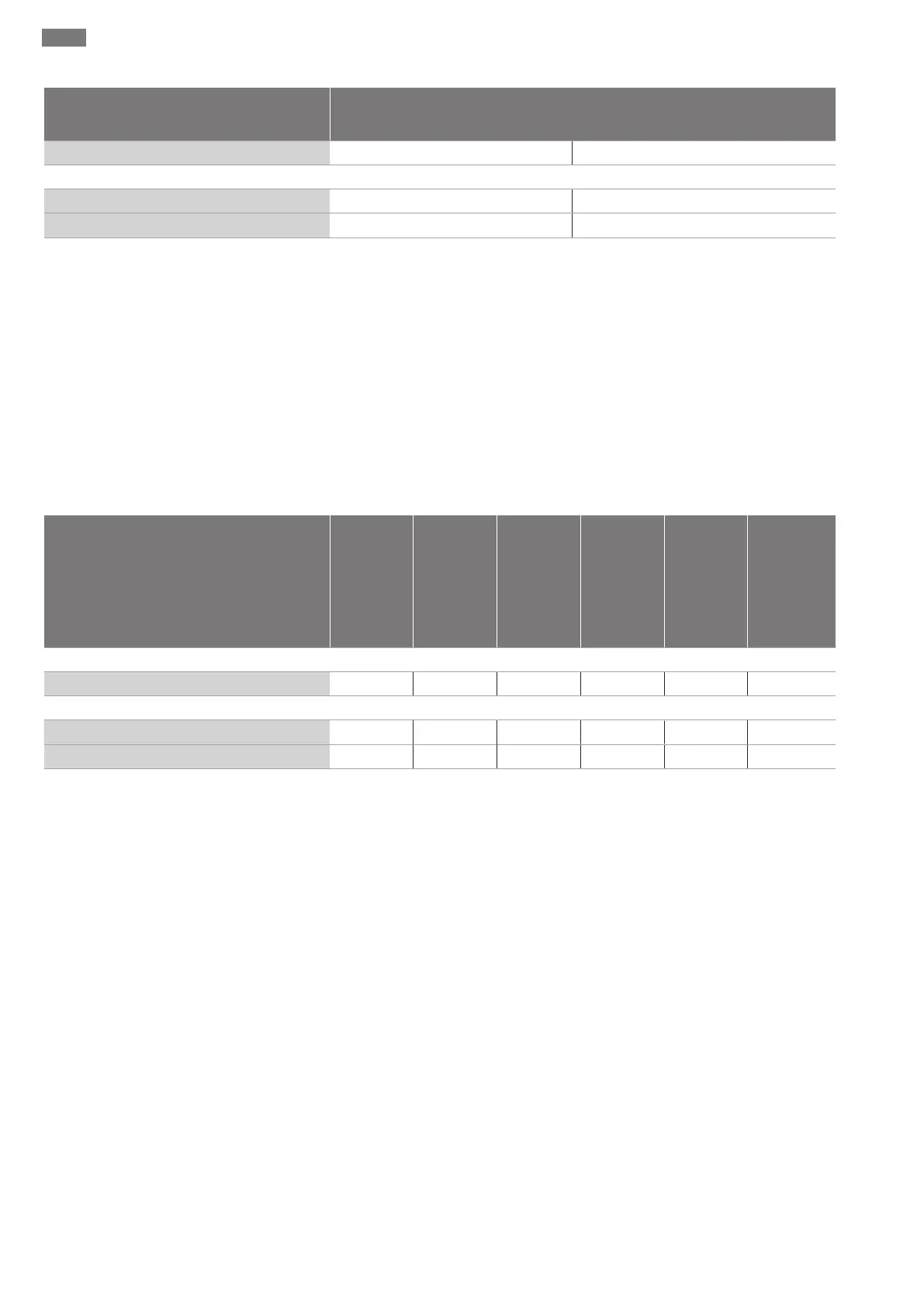

Motor type Sealing chamber

White oil

T17.3L...K...

2.9l 98US.fl.oz.

T20.2 motor

T20.2M...G...

1.8l 61US.fl.oz.

T20.2M...K...

1.1l 37US.fl.oz.

9.3.2 Oil types

ƒ ExxonMobile: Marcol52

ƒ ExxonMobile: Marcol82

ƒ Total: FinavestanA80B (NSF-H1 certified)

9.3.3 Grease

ƒ Esso: UnirexN3

ƒ Tripol: Molub-Alloy-Food Proof 823 FM (USDA-H1 approved)

9.4 Maintenance intervals

To ensure reliable operation, maintenance tasks must be carried out regularly. Depend-

ing on the real ambient temperatures, maintenance intervals different from those men-

tioned in the contract can be defined! If strong vibrations occur during operation, the

pump and the installation must be checked regardless of the defined maintenance in-

tervals.

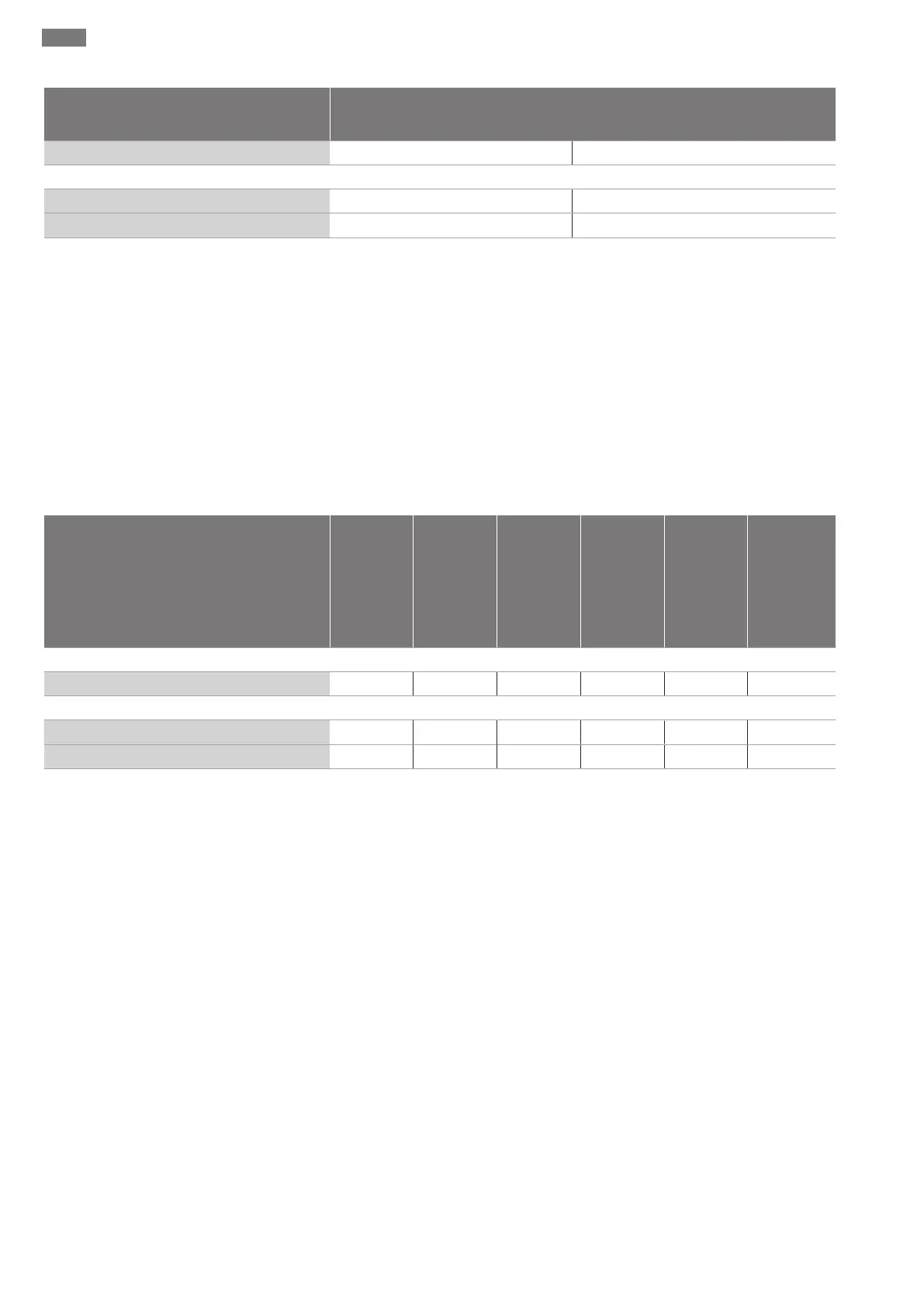

9.4.1 Maintenance intervals for normal

conditions

8000operating hours or after 2years at the latest

Visual inspection of

the connection

cables

Visual inspection of

accessories

Visual inspection of

the coating and

housing for wear

Function test of

monitoring devices

Sealing chamber oil

change*

Draining the leakage

chamber*

Asynchronous motors

T 20.2

• • • • • •

Permanent magnet motors

T 17.3...-P

• • • • o −

T 20.2...-P

• • • • o o

Key

• = Carry out maintenance measures, o = Carry out maintenance measure as instructed,

− = Maintenance measure omitted

* Note information in "Deviating maintenance intervals"!

15000operating hours or after 10years at the latest

ƒ Complete overhaul

9.4.2 Deviating maintenance intervals

Motors without Digital Data Interface

It is possible to install external sealing chamber control (pencil electrode) in motors

without Digital Data Interface. Change the oil as instructed if this monitoring type has

been installed!

Motors with Digital Data Interface

In motors with Digital Data Interface the sealing and/or leakage chamber is monitored

by capacitive sensors. The Digital Data Interface outputs a warning once the predefined

threshold has been reached. Carry out the corresponding maintenance measure if this

warning is displayed.

9.4.3 Maintenance intervals for harsh

conditions

Under harsh operating conditions, specified maintenance intervals must be shortened if

required. Harsh operating conditions include:

ƒ Fluids with long-fibre components

ƒ Turbulent inlet (e.g. due to air intake, cavitation)

ƒ Strongly corroding or abrasive fluids

ƒ Heavily gas generating fluids

ƒ Operation at an unfavourable duty point

Loading...

Loading...