en Appendix

98 WILO SE 2019-10

14 Appendix

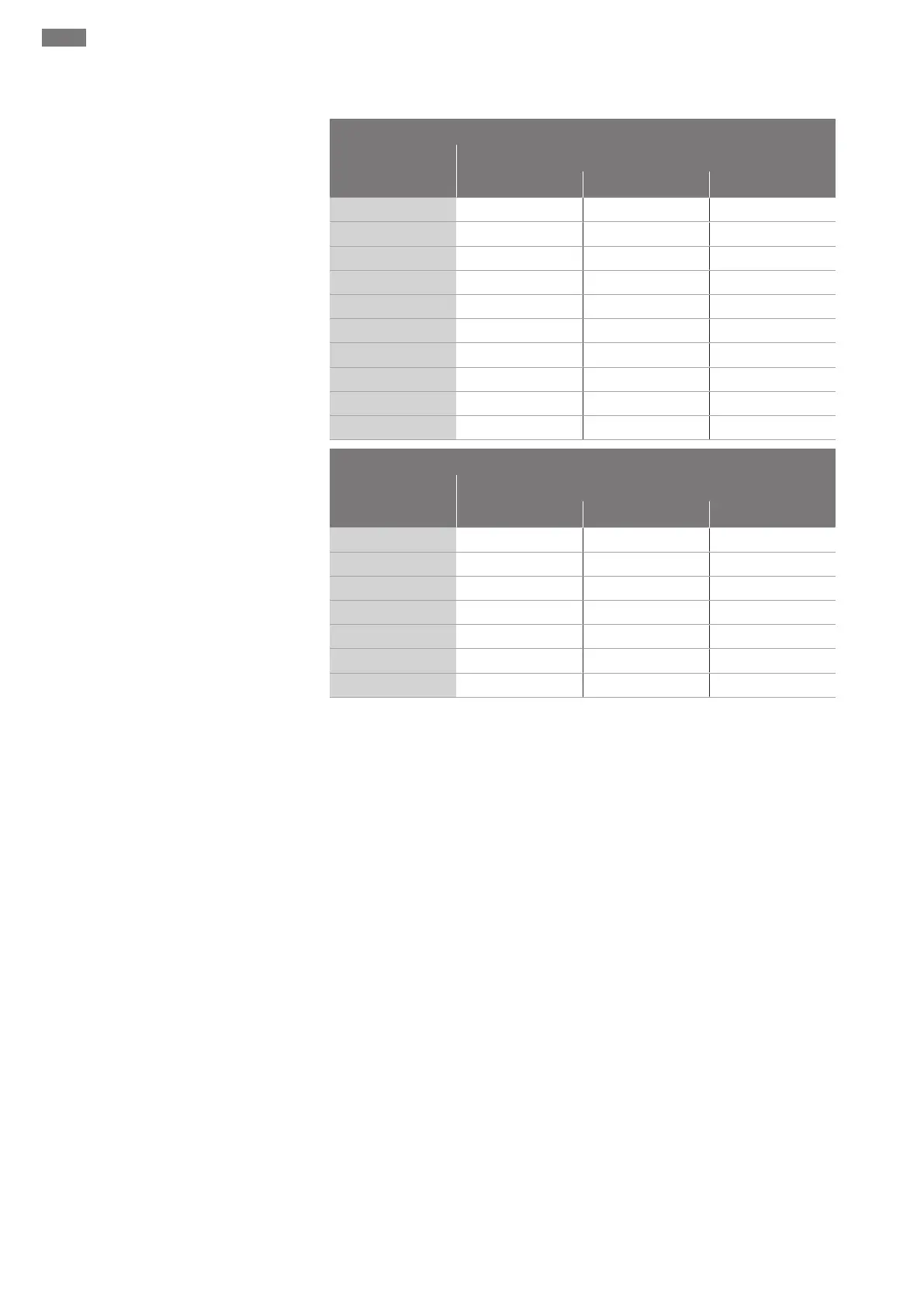

14.1 Tightening torques

Rust-free screws A2/A4

Threaded Tightening torque

Nm kp m ft·lb

M5

5.5 0.56 4

M6

7.5 0.76 5.5

M8

18.5 1.89 13.5

M10

37 3.77 27.5

M12

57 5.81 42

M16

135 13.77 100

M20

230 23.45 170

M24

285 29.06 210

M27

415 42.31 306

M30

565 57.61 417

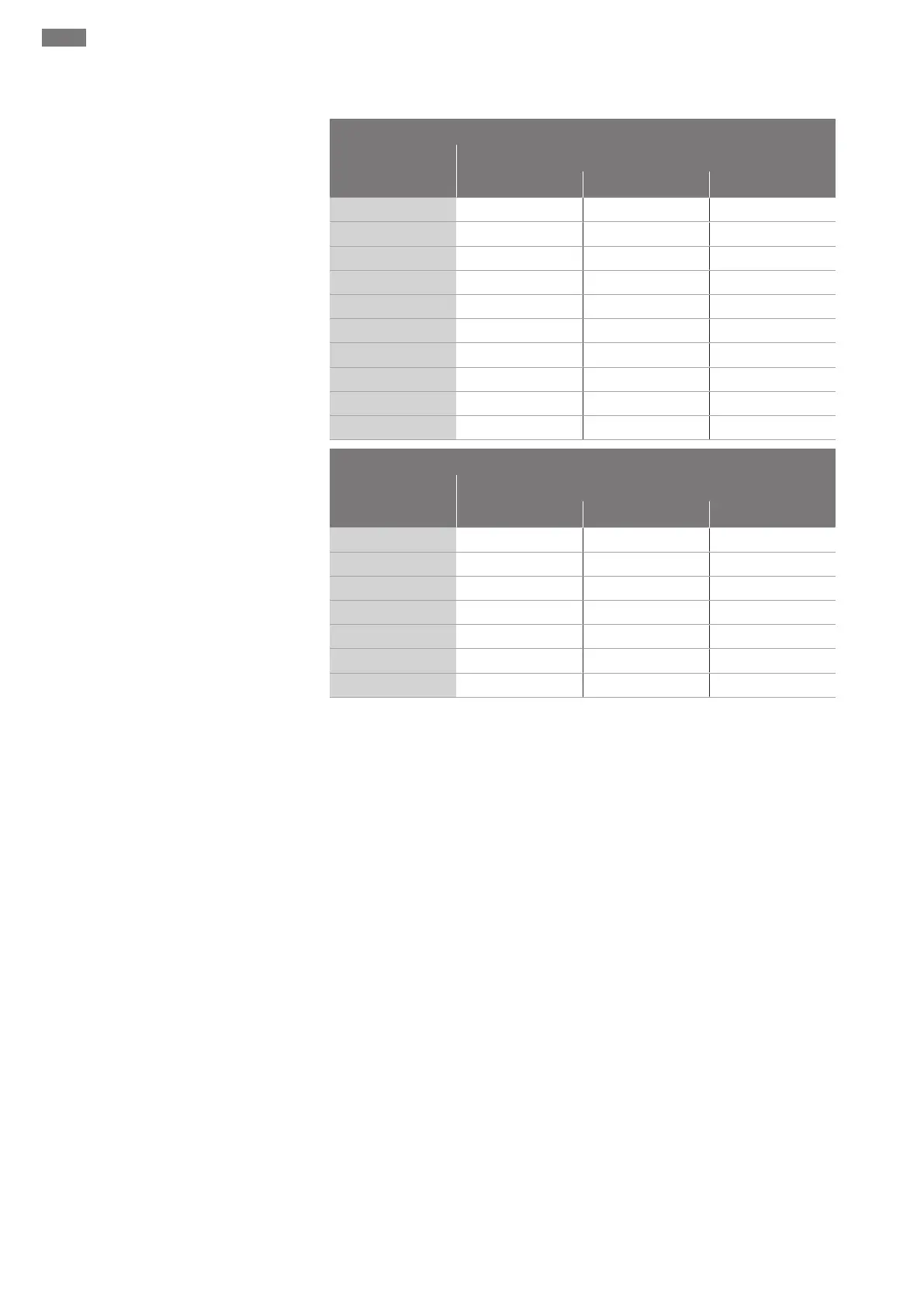

Geomet-coated screws (strength 10.9) with Nord-Lock washer

Threaded Tightening torque

Nm kp m ft·lb

M5

9.2 0.94 6.8

M6

15 1.53 11

M8

36.8 3.75 27.1

M10

73.6 7.51 54.3

M12

126.5 12.90 93.3

M16

155 15.81 114.3

M20

265 27.02 195.5

14.2 Frequency converter operation

The motor in series design (confirming to IEC60034‑17) can be operated with a fre-

quency converter. Contact customer service if the rated voltage is over 415V/50Hz or

480V/60Hz. As a result of the additional heating caused by harmonics, the rated power

of the motor must be around 10% more than the power requirement of the pump. For

frequency converters with a low-harmonic output, it may be possible to reduce the

10% power reserve. Harmonic waves are reduced by means of output filters. The fre-

quency converter and filter must be compatible.

The configuration of the frequency converter depends on the rated motor current.

Make sure that the pump operates without jerking or vibration, specifically in the lower

speed range. Otherwise, the mechanical seals may leak or be damaged. The flow rate in

the pipe must also be observed. A low flow rate increases the risk of solids depositing in

the pump and piping. A minimum flow rate of 0.7m/s (2.3ft/s) with a pumping pressure

of 0.4bar (6psi) is recommended.

It is important that the pump operates across the entire control range without vibra-

tions, resonance, oscillation or excessive noise. Increased motor noise caused by the

harmonics of the power supply is normal.

During parameter configuration of the frequency converter, observe the setting of the

quadratic characteristic curve (U/f curve) for pumps and fans! The U/f characteristic

curve ensures that the output voltage at frequencies below the rated frequency (50Hz

or 60Hz) is adjusted to the power requirement of the pump. More recent frequency

converters feature an automatic power optimisation function – this automation

achieves the same effect. For the frequency converter setting, refer to its installation

and operating instructions.

Motor monitoring faults may occur in motors operated with a frequency converter de-

pending on the type used and the installation conditions. The following measures can

help to reduce or avoid these faults:

ƒ Keeping within the limit values stated in IEC60034‑25 for overvoltage and rise

speed. Output filters may need to be installed.

Loading...

Loading...