Maintenance and repair en

Installation and operating instructions Wilo Motor T 17.3, 20.2:, EMU FA, Rexa SUPRA, Rexa SOLID 89

Mechanical screw locking device

The mechanical screw locking device consists of two Nord-Lock wedge lock washers.

The screw connection is secured by the clamping force. The Nord-Lock screw locking

device must only be used on bolts with strength class 10.9 which have been coated

with Geomet. The use of stainless screws is prohibited!

9.6.2 Which repair work may be carried

out

ƒ Changing the hydraulics housing.

ƒ SOLID G- and Q impeller: Readjusting the suction port.

9.6.3 Changing the hydraulics housing

DANGER

Dismantling the impeller is prohibited!

Depending on the impeller diameter, the impeller must be removed for dismantling

the hydraulics housing on some pumps. Before carrying out any work, check whether

dismantling the impeller is necessary. If yes, notify customer service! The dismant-

ling of the impeller must be carried out by customer service or an authorized special-

ist workshop.

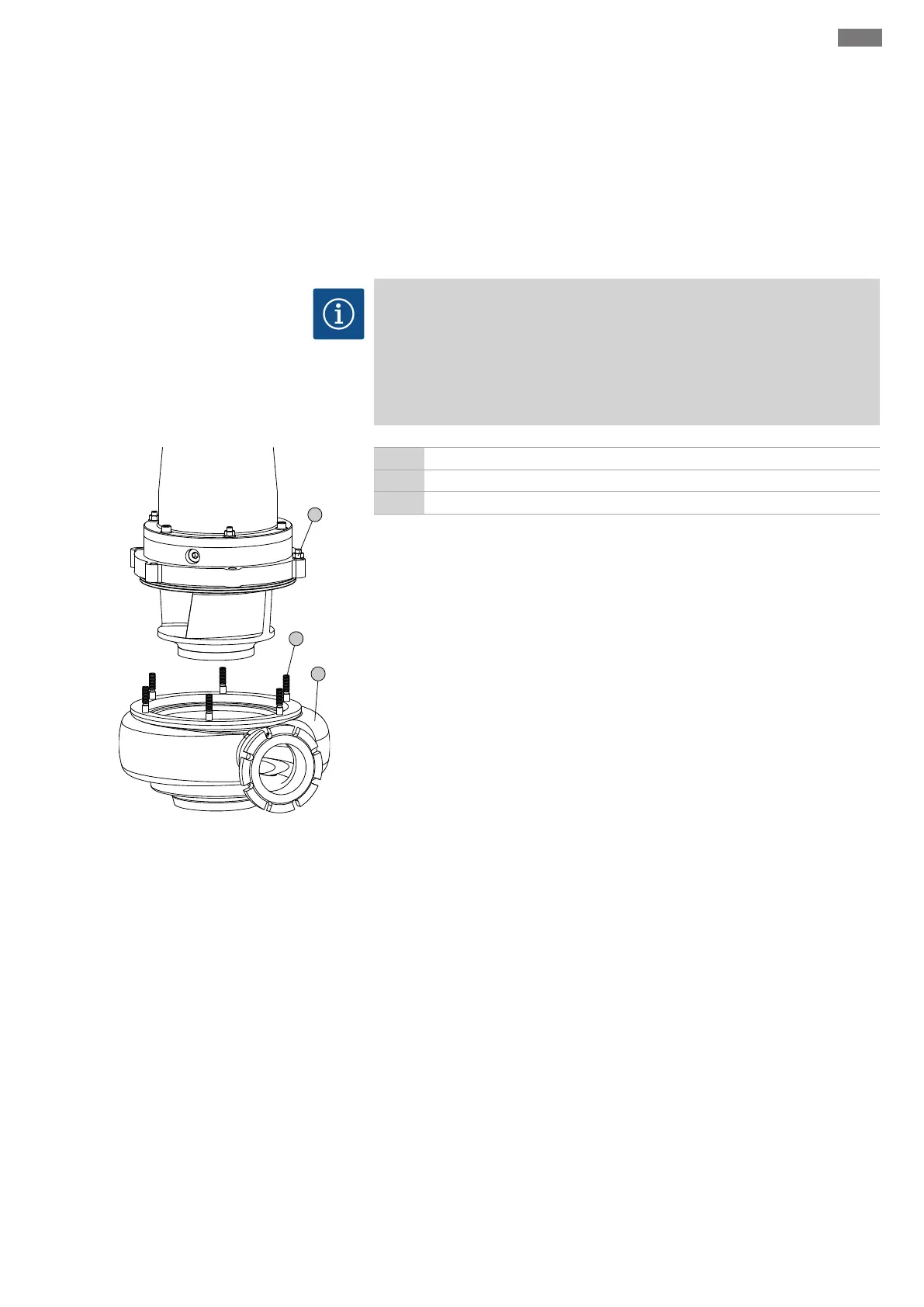

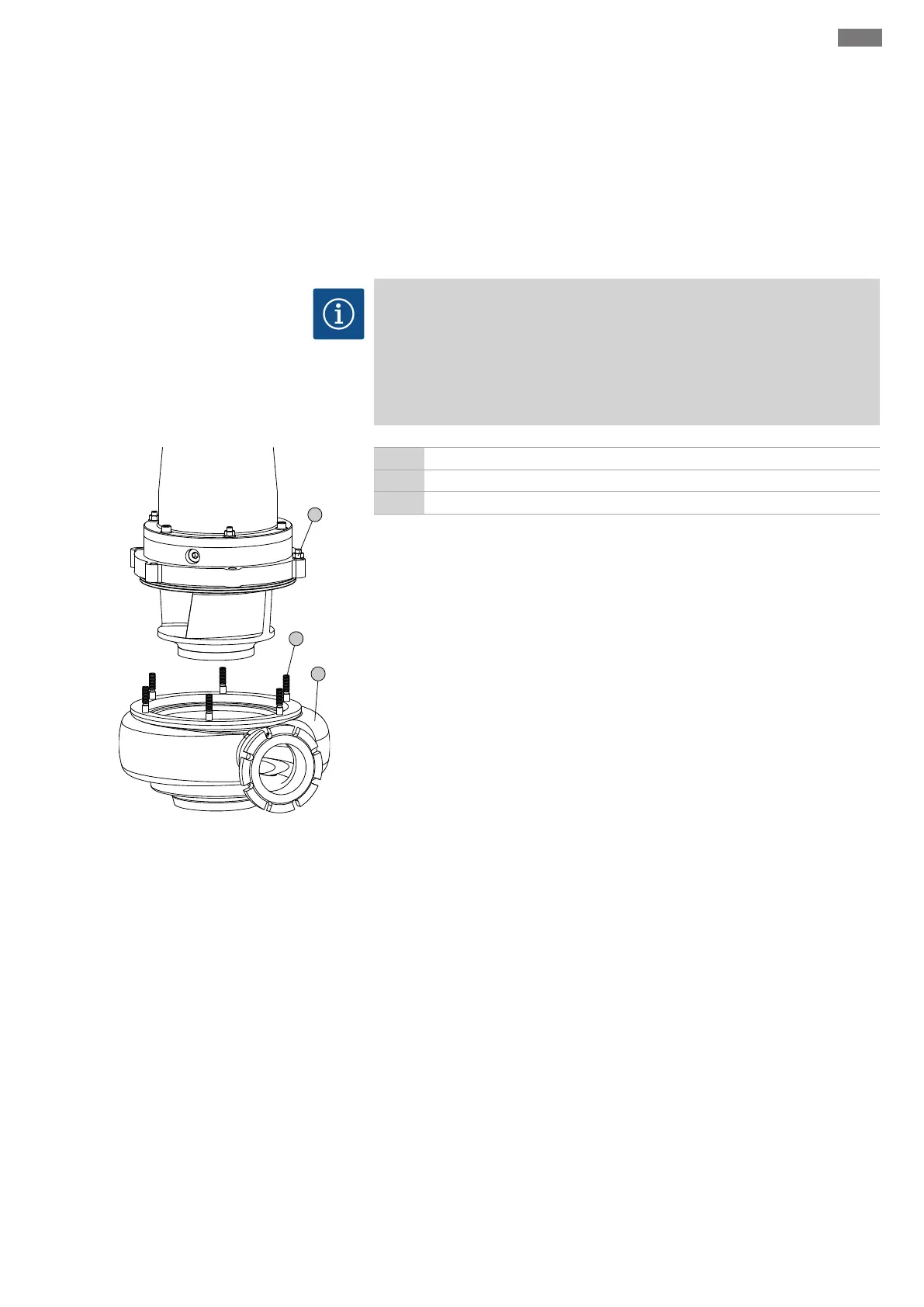

Fig.14: Changing the hydraulics housing

1 Hexagon nuts for fixation of the motor/hydraulics

2 Hydraulics housing

3 Threaded bolt

‡ Lifting equipment with sufficient bearing capacity is available.

‡ Protective equipment is used.

‡ New hydraulics housing is ready.

‡ Impeller must not be dismantled!

1. Attach lifting equipment with suitable lifting gear to the attachment point of the

pump.

2. Position the pump upright.

CAUTION!The hydraulics housing will be damaged if the pump is put down too

quickly. Set the pump down slowly on the suction port!

NOTICE!If the pump cannot be placed level on the suction port, use appropriate

adjustment plates. The pump must be positioned vertically to be able to lift the

motor without issues.

3. Mark the motor/hydraulics position on the housing.

4. Undo and remove hexagon nuts at the motor flange.

5. Slowly lift the motor and pull it off the hydraulics housing.

CAUTION!Lift the motor vertically and do not tilt! Threaded bolts are damaged

if the unit is tilted!

6. Insert a new seal ring at the motor flange.

7. Swivel the motor over the new hydraulics housing.

8. Slowly lower the motor. Make sure that the motor/hydraulic markings match and

the threaded bolts screw exactly into the drilled holes.

9. Screw hexagon nuts and connect the motor to the hydraulics firmly. NOTICE!Ob-

serve the tightening torques stated in the appendix!

▶ Hydraulics housing changed. Pump can be reinstalled.

WARNING!If the pump is placed in temporary storage and the lifting equipment is

dismantled, secure the pump against falling over and slipping!

Loading...

Loading...