24

OPM-171/B

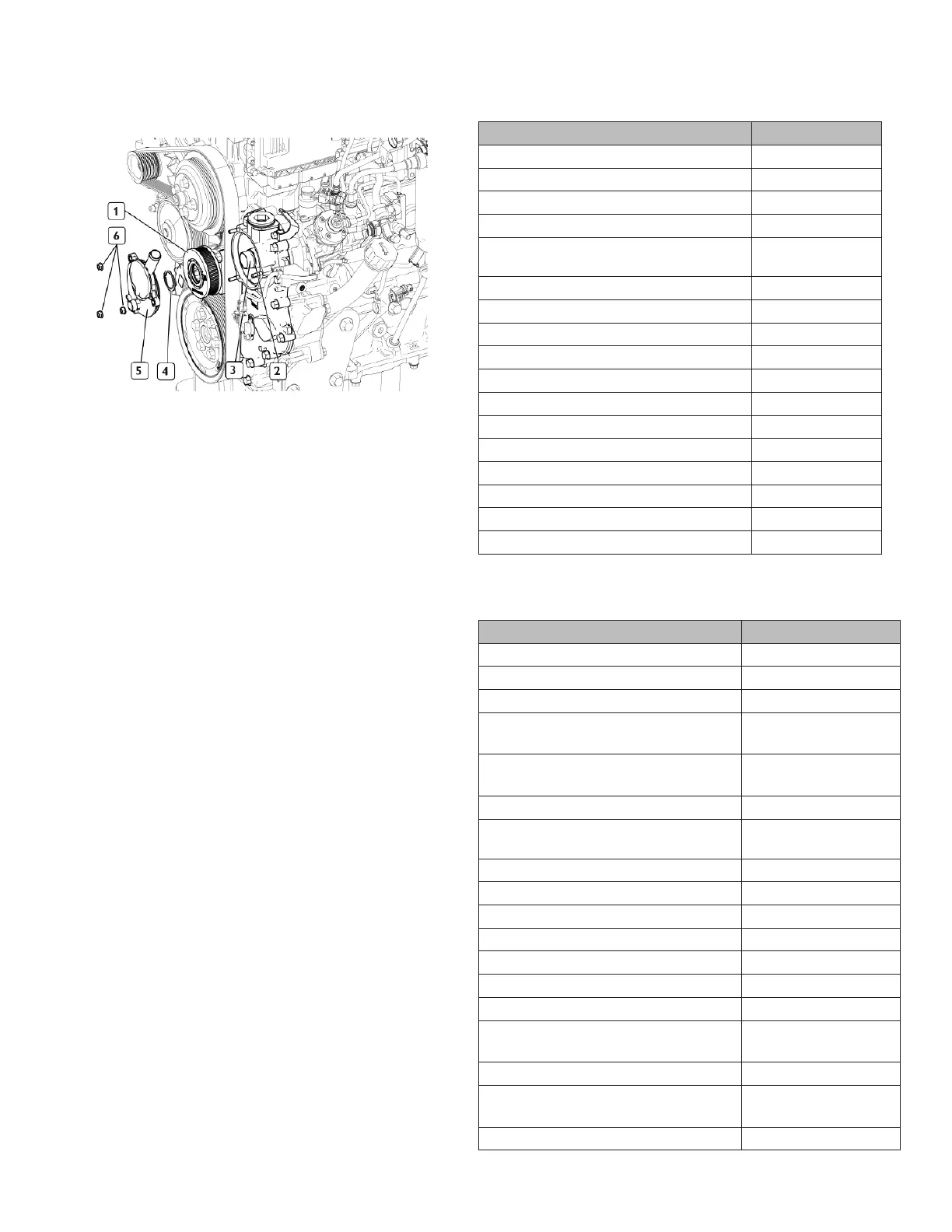

MAINTENANCE SCHEDULE

ENGINE

Checks In Period of Use Frequency

Check for water in the fuel Pre-Filter Daily

Check Air-Restriction Indicator on Filter Daily

Engine Oil Level Daily/Prior to Use

Engine Coolant Level Daily/Prior to Use

Tension and Condition Check of

Ancillary Belt

600 Hours

Engine Oil Replacement 600 Hours

Oil Filter Replacement 600 Hours

Fuel Pre-Filter Replacement 600 Hours

Fuel Filter Replacement 600 Hours

Clean Radiator 600 Hours

Air Filter Replacement 1200 Hours

Change Blow-By Filter 1800 Hours

Ancillary Belt Replacement 3000 Hours

Turbocharger Visual Inspection 1200 Hours

Alternator Visual Inspection 3600 Hours

Clean/Replace Radiator Cap 3600 Hours

Engine Coolant Replacement 3000 Hours

Note: Some operating conditions may require more

frequent maintenance intervals.

COMPRESSOR

Checks In Period of Use Frequency

Oil Level Daily/Prior to Use

Drain air/water from system Daily/Prior to Use

Check oil level 50 Hours

Tighten all screw pipe fittings &

electrical screw terminal fittings

50 Hours

Check all other connections for firm

seating

50 Hours

Clean air filter 100 Hours

Inspect complete air system for

damage/leaks

250 Hours

Check belt tension 250 Hours

Check function of safety valves 250 Hours

Check Pulley tension and alignment 250 Hours

Replace fine separator cartridge 2000 Hours/Annually

Change oil and replace 2000 Hours/Annually

Replace oil filter 2000 Hours/Annually

Replace filter element in intake air filter 2000 Hours/Annually

Check system for leaks and inspect

system

2000 Hours/Annually

Clean air/oil cooler 2000 Hours/Annually

Check fan for cracks or other damage

and clean

2000 Hours/Annually

Clean external compressor surfaces 2000 Hours/Annually

6. Correctly position the guards inserting the anti-

vibration plugs.

7. Secure the other guards.

STORAGE

PREPARING THE ENGINE FOR A LONG PERIOD

OF INACTIVITY

In the case of a planned period of inactivity that lasts longer

than two months, to prevent the interior parts of the

engine and some components of the injection system from

oxidizing, prepare the engine as follows:

1. Drain the lubricant oil from the sump after heating the

engine.

2. Pour 30/M protective oil into the engine up to the

“minimum” level indicated on the oil level dipstick. Start

the engine and run it for approx. 5 min.

3. Drain the fuel from the injection circuit, from the filter

and from the injection pump channels.

4. Connect the fuel circuit to a tank containing CFB

protective liquid (ISO 4113) and introduce the liquid by

pressurizing the circuit and driving the engine for

approx. 2 min. after excluding injection system

operation.

The operation required can be completed by directly

polarizing terminal 50 of the electric starter motor with

positive voltage equal to that of the nominal system voltage,

using the designated conductor.

5. Nebulize the 30/M protective oil in a quantity of

approx. 130 g (10 g per liter of displacement) in the

turbocharger intake inlet, during the engine turning

operation described in the previous paragraph.

6. Close all of the engine’s intake, discharge, ventilation

and bleeding holes with plugs or seal them with

adhesive tape.

7. Drain the residual 30/M protective oil from the sump,

which can be used for an additional 2 preparations.

8. Place warning notices of ENGINE WITHOUT OIL on the

engine and dashboard.

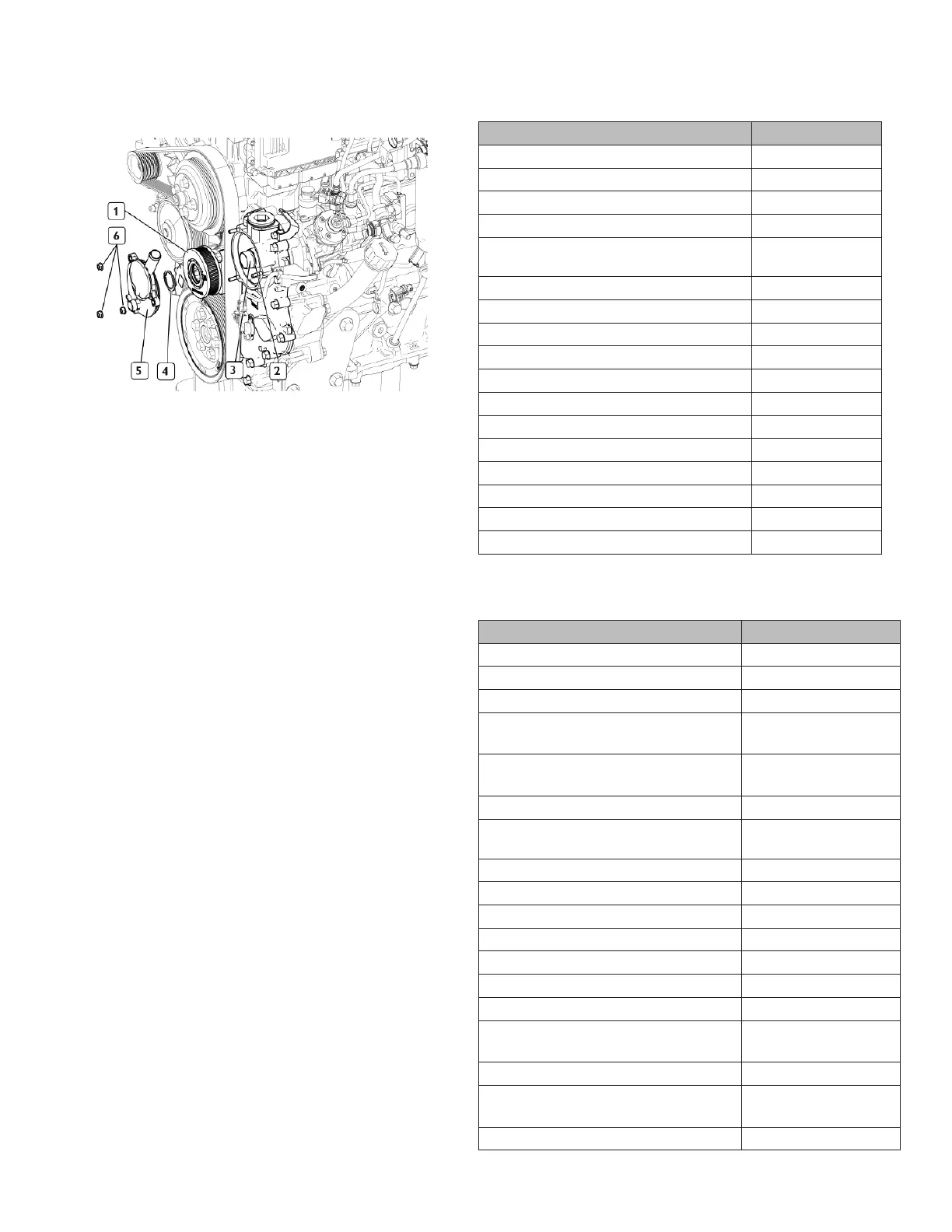

Illustration 3

Loading...

Loading...