1. Intake filter

2. Intake valve

3. Control unit (electric)

4. Screw compressor

5. Separator tank with pre-separation

6. Fine separator

7. Minimum pressure valve

8. Oil thermostat

9. Oil filter

10. Oil cooler

11. Air after-cooler

12. Non-return valve

13. Safety valve

1.2

[en] 02/2014

Installation and operating manual - NK 31ROTORCOMP VERDICHTER

1.5.2 Purpose

The NK 31 is a screw compressor compact mod-

ule designed for installation in a compressed-air

generating station.

The sole intended use of the system is the

compression of atmospheric air. The NK 31 may

only be used to compress gases or other media

following written approval by ROTORCOMP.

The NK 31 may only be installed by specialized

companies with the corresponding know-how.

The safety precautions, technical data, limits, in-

stallation guidelines and regulations for commis-

sioning and operation specified in this operating

manual must be observed and complied with.

1.5.3 Standard delivery scope

With the NK 31, ROTORCOMP offers a com-

pletely equipped, compact compressor module.

The components of the standard delivery scope

are described in the following chapters.

Optionally available components are marked with

(optional).

1.6 Warranty information,

liability disclaimer

ROTORCOMP is a manufacturer of screw com-

pressor components and not of ready-to-operate

compressor systems.

RC shall only be answerable for any defects of

these individual components for which it is re-

sponsible within the scope of the warranty condi-

tions.

Failure to comply with the following instructions

and information shall void any and all liability.

This liability disclaimer also results in the loss of

claims for damages. This applies in particular in

case of:

– Installation not approved by RC

– Improper use

– Operation of the compressor outside the speci-

fied limits

– Failure to observe the safety precautions and

the usual care and caution

– Unsuitable operating materials (gases, oils)

– Condensate in the screw compressor

– Corrosion as subsequent damage

– Improper operation

– Insufficient maintenance, missing proof of

maintenance

– Use of unsuitable tools

– Failure to use genuine spare parts

– Unauthorized modifications to the screw com-

pressor module and/or its components–

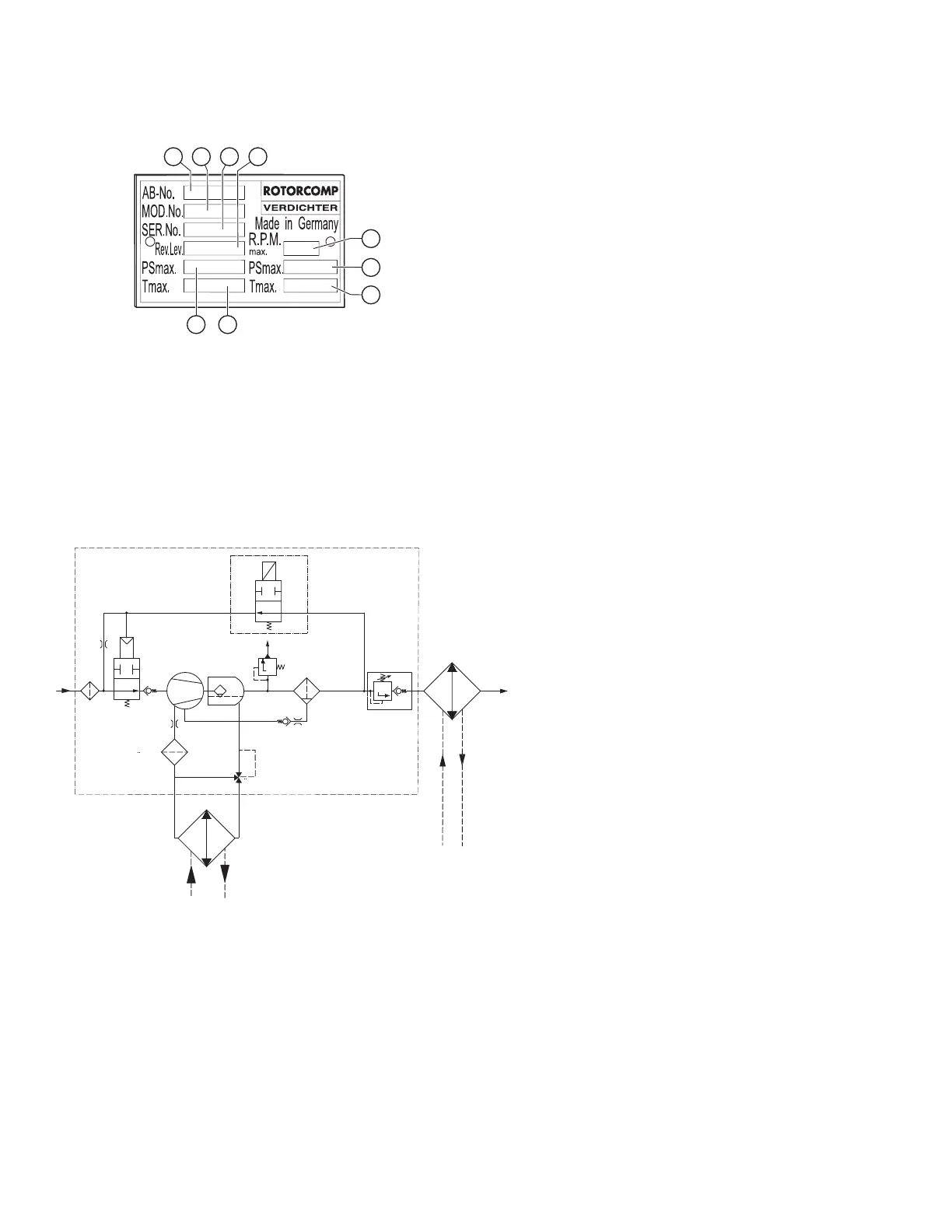

1.7 Nameplate

For the location of the nameplate, see Figure 3-1

or 3-3.

Should you have questions, please provide us

with the data on the nameplate. This ensures that

you receive the correct information.

Figure 1-1

Stamping for customers outside Germany

(Europe)

1. Order No.

2. Model

3. Serial No.

4. Year of manufacture

5. Max. rpm

6. Max. operating pressure in psi

7. Max. operating temperature °F

8. Max. operating temperature °C

9. Max. operating pressure in bar

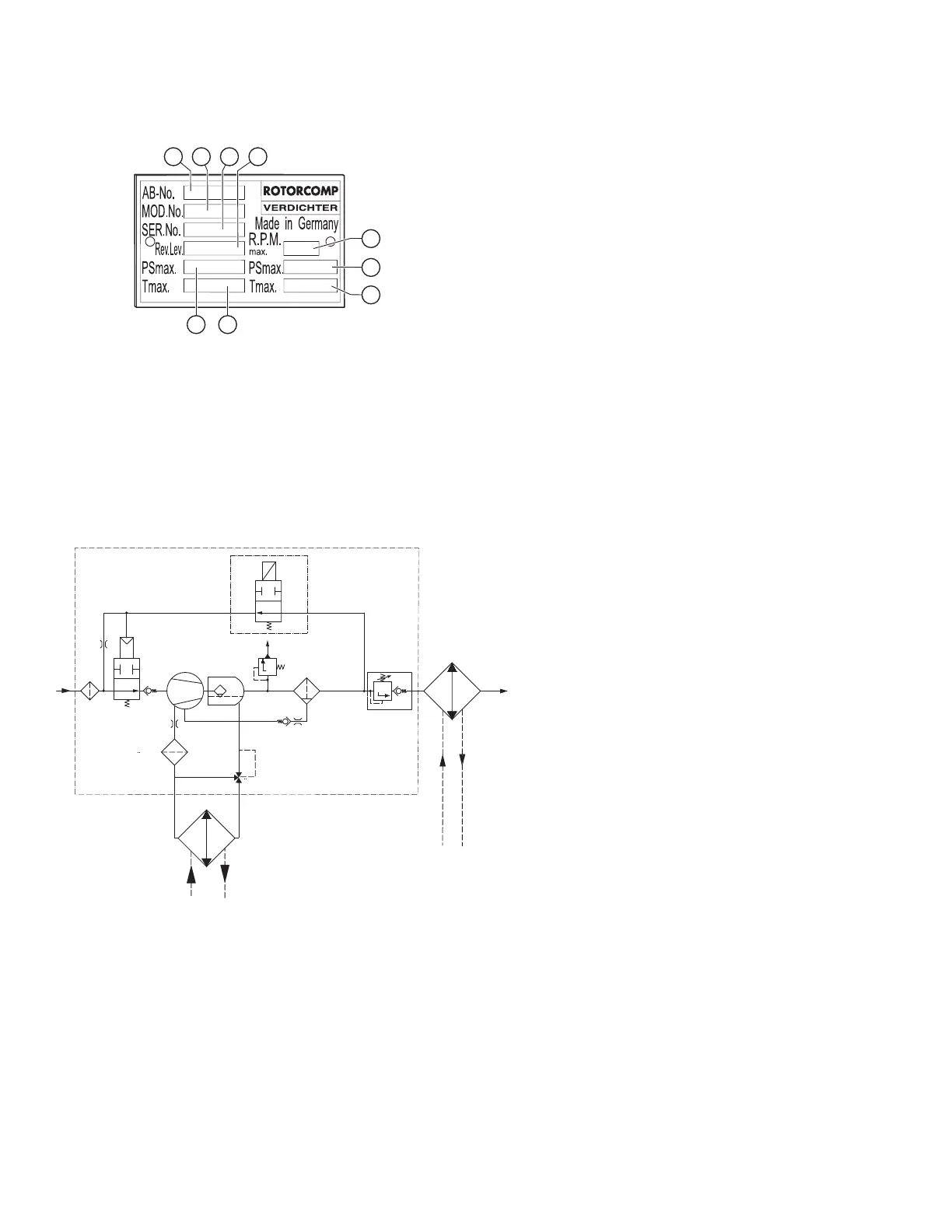

Figure 3-2

3.2 Flow diagram of NK 31

(electric control unit)

3.3 Operating description for NK 31

Screw Compressor Compact Module

(electric)

The flow diagram shows a schematic view of the

operating principle and the arrangement of the

main components of the NK 31 screw compres-

sor module with electrical control unit, regardless

of any other equipment.

3.3.1 Standstill

At standstill the solenoid valve 3.1 is deener-

gized, the relief line is open and the downstream

devices are depressurized. The minimum pres-

sure valve 7 set to approx. 5.5 bar at the factory

is tightly closed. The intake valve 2 is slightly

open at standstill.

Loading...

Loading...