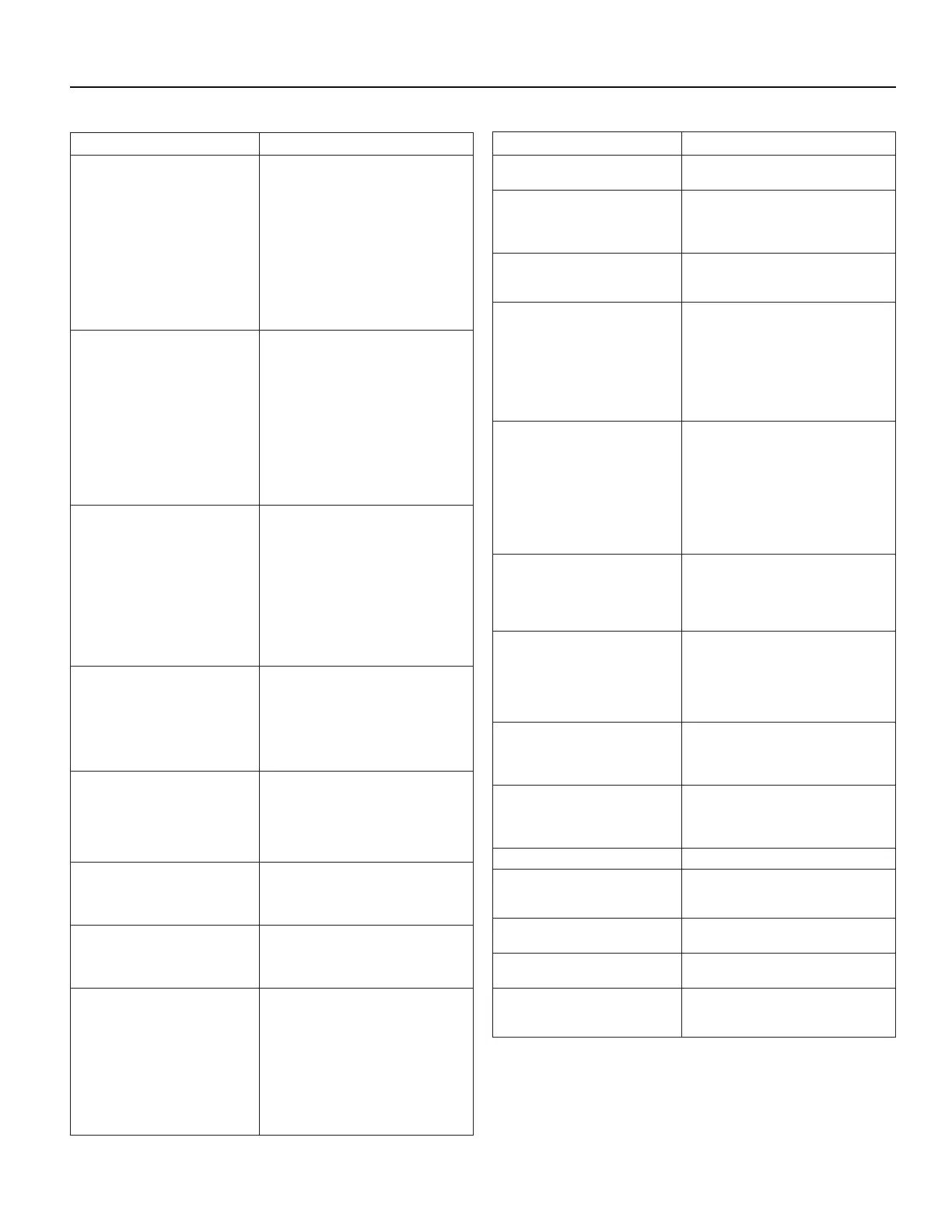

25 OPM-171/B

COMPRESSOR

Problem Possible Causes

System does not start No electricity, verify voltage at

solenoid

System difficult to start Verify engine speed is correct

Compressor is flooded with oil

System has not been discharged

Oil too viscous

Differential pressure Pressure in separator cartridge too

high with clogged or full

separator cartridge

High temp shutdowns Oil shortage

Oil filter soiled

Thermostat defective

Oil cooler soiled

Incorrect installation

1. Room ventilation

2. Exhaust air blocked

3. Thermal short circuit

Safety valve blows off Safety valve defective

Fine separator cartridge soiled

System does not relieve continuous

operation

System does not switch off

automatically (drop-out mode)

Freeze up of pressure switch due to

starting compressor before

engine is fully warmed up

Oil in compressed air Oil extraction line with nozzle in oil

sight glass soiled

Fine separator cartridge defective

Oil in oil reservoir too high; possibly

excessive condensation

System does not discharge

during continuous operation,

system does not switch off

automatically in case of

intermittent operations, i.e.

safety valve blows off

Upper switching point of network

pressure monitor set too high

Solenoid valve defective - Relief

valve defective

Minimum pressure valve jammed

System continually discharges,

low feed quantity

Solenoid valve defective - Relief

valve defective

Break in electric supply line to

solenoid valve

No or insufficient feed quantity Intake filter soiled

Oil shortage

Intake control valve does not open

Leaks in system

Control valve does not close Pressure switch or control valve

Oil exits through intake control

valve during stop

Sealing surface on intake control

valve damaged, spring in intake

control valve broken

System does not relieve Solenoid valve/electrical system

Impulse-pressure relief valve

Control valve constantly

discharges

Solenoid valve/electrical system

Oil escapes during discharge

(oil foam in the separator

cartridge)

Oil type incorrect

Oil foam forms during stop

Oil level too high

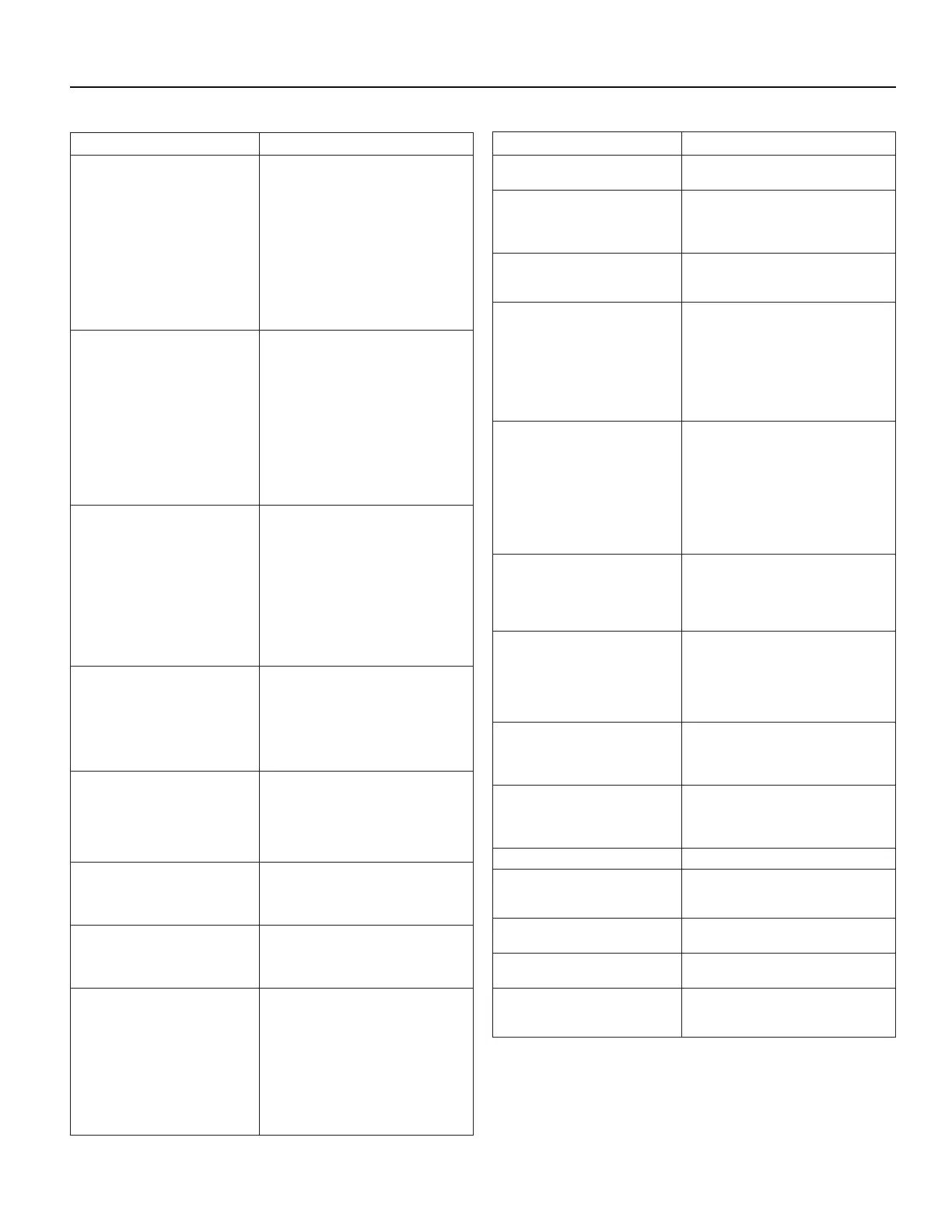

TROUBLE SHOOTING

ENGINE-GENERATOR SET

Problem Possible Causes

Unit will not crank when

power fails

Digital genset not in AUTO

Transfer control switch not in

AUTOMATIC position

Incorrect wiring between ATS and

genset

Defective control relay in ATS

Fuse(s) blown in the DSE 7310

Defective DSE 7310

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Low/dead battery

Engine won’t crank Low/dead battery

Blown DC fuses

Defective DSE 7310

Defective key switch

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Locked up engine genset

Defective engine harness

Improper battery voltage to start

solenoid, fuel pump, or fuel

solenoid

Engine cranks but will not start Improper fuel delivery to the unit

Fuel supply shut off

Fuel tank empty

Air in the fuel system

Engine fuel solenoid has not

opened

Defective fuel pump

Defective fuel solenoid

Defective engine harness

Improper battery voltage to fuel

pump or fuel solenoid

Engine starts, then stops and

alarm light comes on

Engine oil pressure is low

Engine has high water temperature

Engine has overspeed

Engine has gone into overcrank

No output from AC generator

Loss of speed signal

Loss of run signal

Engine will not come up to

speed after it starts

Insufficient fuel volume getting to

the unit

1. Too small of fuel line

2. Fuel racks not open properly

Governor is defective

AC short in generator components

ATS will not transfer to

Emergency Supply (generator)

No AC generator output

Defective ATS control board. See

ATS manual

Circuit breaker open or defective

ATS will not re-transfer to

normal power

Proper power line not available at

line terminals in ATS panel

Defective ATS control board. See

ATS manual

No AC output from generator Defective diode

Defective voltage regulator

Defective rotor

Defective stator

Defective exciter rotor

Defective exciter stator

AC short in the output leads

Defective/open generator output

breaker

Wiring error

Loading...

Loading...