- Applications - 26

RECIRCULATION RATES AND PUMP CAPACITY

Recirculation factor Recirculation flow in m³/hr per 100 kW*

Refrigerant CO

2

NH

3

R22 CO

2

NH

3

R22

Air Cooler 1,2 – 2,0

3 - 4 2 - 3 1,4 – 2,4 1,3 – 1,8 2,8 – 4,3

Plate Freezer

5 - 10 7 - 10 5 - 10 6 - 12 3 – 4,5 6,5 - 13

Liquid Chiller

1,2 – 1,5 1,2 – 1,5 1,2 – 1,5 1,4 – 1,6 0,6 1,7

*) including re-circulation rate

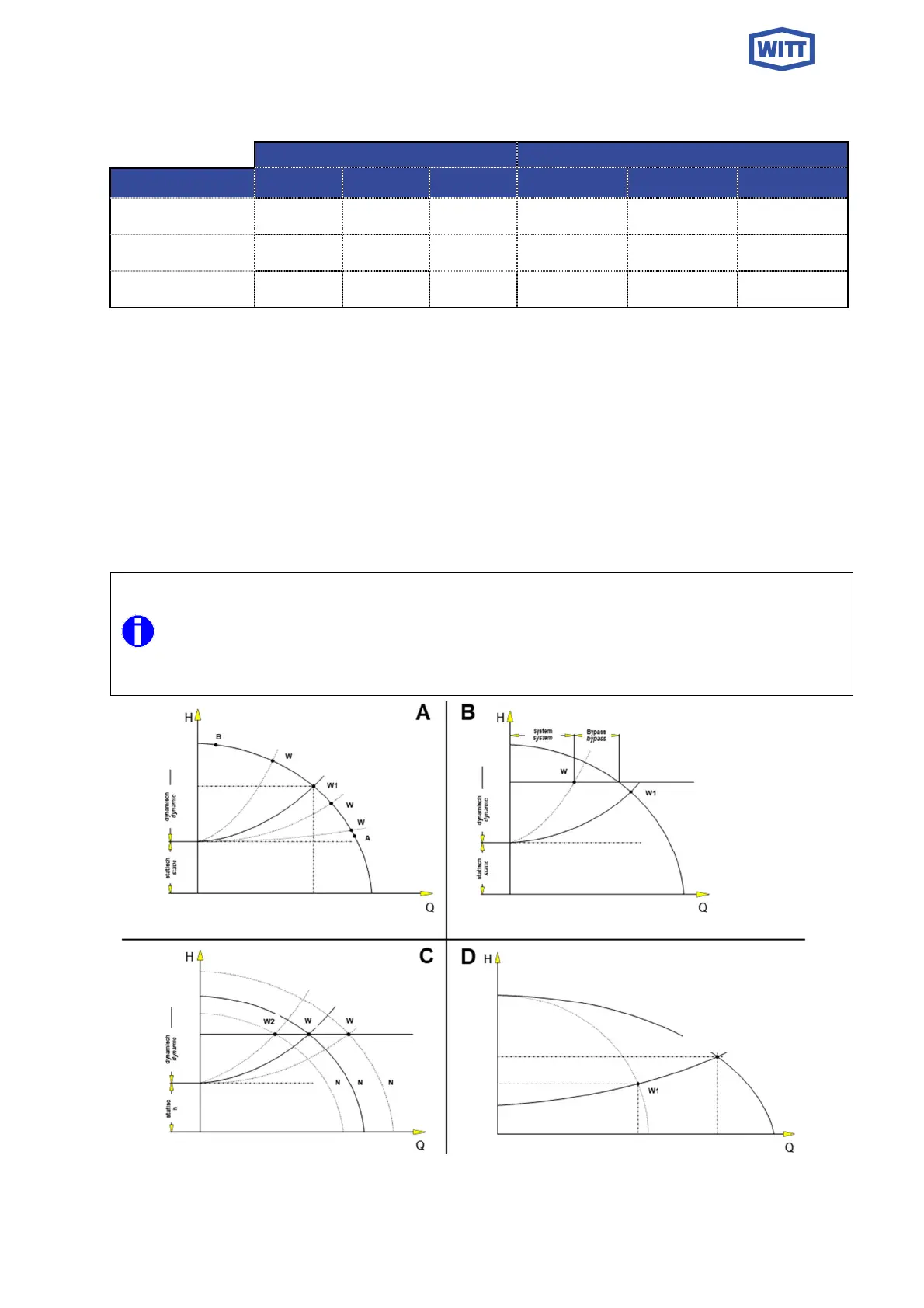

5.4 ADAPTATION TO PLANT REQUIREMENTS

Fig. 5 shows different plant operating conditions. The delivery head H is shown in relation to

the required plant capacity Q.

Performance curve characteristics of the refrigerant pump are shown in fig 5A. The different

points W mark the varying plant conditions that may occur during operation.

If the required liquid flow does not correspond with the available pump capacity then the liquid

flow to the sys-tem can be adjusted as follows:

pump capacity too large:

switch off a pump

open a liquid bypass valve, fig. 5B

speed control of the pump, fig 5C

pump capacity too small:

switch on an extra pump, fig 5D

install a larger pump

Fig. 5, A-D

V

1

+V

2

≠ 2 x V

1

Loading...

Loading...