24 Assembly

MAN1260 (4/09/2018)

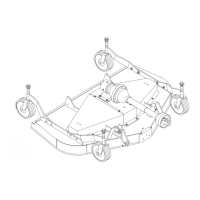

Figure 35

. Quick Hitch Kit Installation (Optional)

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

Inspect the equipment thoroughly after assembly to ensure it is set up properly

before delivering it to the customer.

The following check lists are a reminder of points to inspect. Check off each

item as it is found satisfactory or after proper adjustment is made.

___ Check that all safety decals are installed and in good condition.

Replace if damaged.

___ Check that shields and guards are properly installed and in good

condition. Replace if damaged.

___ Check all bolts to be sure they are properly torqued.

___ Check that all cotter pins and safety pins are properly installed.

Replace if damaged.

___ Check and grease all lubrication points as identified in “Lubrication

Information” on page 12.

___ Gearboxes are not filled at the factory. Prior to delivery, fill as spec-

ified in the “Owner Service, lubrication information” on page 12 and

check to see that there are no leaking seals.

___ Check that blades have been properly installed.

DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

___ Show customer how to make adjustments and select proper PTO

speed.

___ Instruct customer how to lubricate and explain importance of lubri-

cation.

___ Point out the safety decals. Explain their meaning and the need to

keep them in place and in good condition. Emphasize the

increased safety hazards when instructions are not followed.

___ Present Operator's Manual and request that customer and all oper-

ators read it before operating equipment. Point out the manual

safety rules, explain their meanings and emphasize the increased

safety hazards that exist when safety rules are not followed.

___ Show customer how to make sure driveline is properly installed and

that spring-activated locking pin or collar slides freely and is seated

in groove on tractor PTO shaft.

___ Show customer the safe, proper procedures to be used when

mounting, dismounting, and storing equipment.

___ Explain to customer the potential crushing hazards of going under-

neath raised equipment. Instruct that before going underneath to

disconnect the driveline, securely block up all corners with jack-

stands and to follow all instructions in the “Owner Service, Blocking

Methods” section of the Operator’s Manual. Explain that blocking

up prevents equipment dropping from hydraulic leak down, hydrau-

lic system failures or mechanical component failures.

___ For mounted units, add wheel weights, ballast in front tires, and/or

front tractor weight to enhance front end stability. A minimum 20%

of tractor and equipment gross weight must be on front tractor

wheels. When adding weight to attain 20% of tractor and equip-

ment weight on front tractor wheels, you must not exceed the

ROPS weight certification. Weigh the tractor and equipment. Do

not estimate!

___ Make customer aware of optional equipment available so that cus-

tomer can make proper choices as required.

___ Point out all guards and shields. Explain their importance and the

safety hazards that exist when not kept in place and in good condi-

tion.

CHAIN CUT-TO-LENGTH CHART

Model Dimension “A”

PRD6000E 1016 mm (40")

PRD7200E 1143 mm (45")

PRD8400E 1270 mm (50")

NOTE:

This kit is used on other models. Use only the hardware listed below.

1. Offset link, 9.5 x 50.8 x 381 mm (.38 x 2 x 15")

2. Chain, 9.5 mm (3/8") proof coil 38-link

3. Sleeve, 23.8 x 36.5 x 49.2 mm (.94 x 1.44 x 1.94")

4. Screw, 1/2 NC x 6 HHCS GR5

5. Washer, 1/2" flat

6. Sleeve, 12.7 x 19.1 x 85.7 mm (.50 x .75 x 3.38")

7. Nut, 1/2 NC flange lock

8. Sleeve, 22.2 x 28.6 x 15.1 mm

(7/8 x 1-1/8 x 19/32")

9. Washer, 3/4 flat

10. Sleeve, 20.6 x 31.8 x 45.0 mm (.81 x 1.25 x 1.81")

11. Screw, 3/4 NC x 4-1/2 HHCS

12. Nut, 3/4 NC plated hex

Loading...

Loading...