extends the flue by 750mm up to a maximum of 4m. See table below.

EXTENSION MAXIMUM FLUE LENGTH mm

24CDi 28CDi

35CDi II

1 1475 1475 1475

2 2225 2225 2225

3 2975 2975 2975

4 3725 3000 3000

5 4000

12.9 Measure and Cut the Ducts.

General

: Cut the ducts as necessary, ensuring that the ducts are square

and free from burrs. Always check the dimensions before cutting.

Measure the distance L. Refer to Fig.19 and 20.

The standard flue can be telescopically adjusted to any length between

425mm and 725mm.

Fix the flue assembly together using the self-tapping screws provided.

Refer to Fig.21.

It will only be necessary to cut the standard assembly if L<425mm.

Cut the flue turret assembly and

the terminal assembly by the same

amount i.e L=350 - remove 75mm from each

assembly.

Minimum side flue length = 335mm (accommodating a 10mm

Service clearance and a 100mm wall)

Minimum rear flue length = 297mm (accommodating a 100mm wall)

24CDi 28CDi/35CDi II

If L is between 1175 - 1475mm 1175 - 1475mm (1 extension)

1925 - 2225mm 1925 - 2225mm (2 extension)

2675 - 2975mm 2675 - 2975mm (3 extension)

3425 - 3725mm N/A (4 extension)

it is not necessary to cut the ducts.

24CDi 28CDi/35CDi II

If L is between 725 - 1175mm 725 - 1175mm (1 extension)

1475 - 1925mm 1475 - 1925mm (2 extension)

2225 - 2675mm 2225 - 2675mm (3 extension)

2975 - 3425mm 2975 - 3000mm (4 extension)

3725 - 4000mm N/A (5 extension)

It is necessary to shorten the assembly by cutting the first extension

duct assembly i.e. L = 1000mm - remove 175mm from the air and flue

ducts.

NOTE: Extension duct measurements do not include the socketed end.

Unless specifically instructed the socketed end must not be removed.

Fix the flue ducts together before fixing the surrounding air duct, the

cut ducts fit into the flue assembly.

12.10. Fitting the Flue Assembly with Access to the Terminal.

Prepare the flue duct assembly as described in Section 12.9.

Apply the plastic tape to the air duct in contact with the external

brickwork.

From inside push the assembly through the wall. Align the flue turret

and push fully onto the spigot on the appliance. Tighten

the clamping ring and fix using the screw provided. Refer to Fig.24.

Make good the internal wall face and the external brickwork or

rendering.

Replace the inner casing.

12.11 Fitting of the Flue Assembly without access to the Terminal.

NOTE: A larger diameter opening in the wall is required. Refer to Table 2.

Prepare the flue assembly as described in Section 12.9.

Fit the rubber sealing gasket centrally onto the terminal assembly and

tighten the clamp. Refer to Fig. 23.

Apply the plastic tape to the air duct in contact with the external

brickwork.

From inside push the assembly through the wall so that the

gasket flange is against the outer face. Refer to Fig. 23.

It may be necessary to adjust the legs of the flue centring ring.

Align the flue turret and push fully onto the socket on the appliance.

Tighten the clamping ring and fix using the screw provided. Refer to Fig 24.

Seal the gap around the duct at the inner wall face and make good.

Replace the inner casing.

15

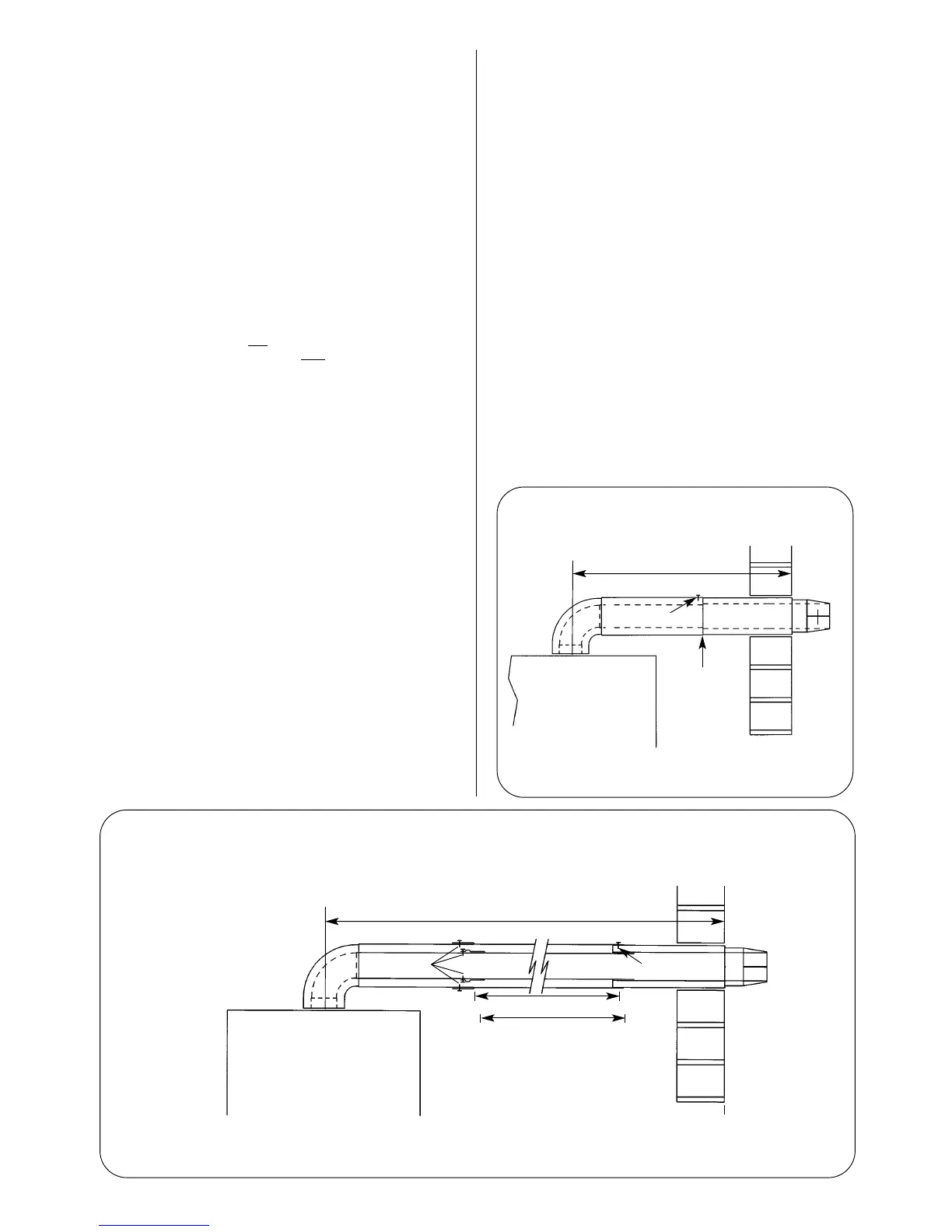

Fig. 21. Flue turret, ducts and terminal

assembly

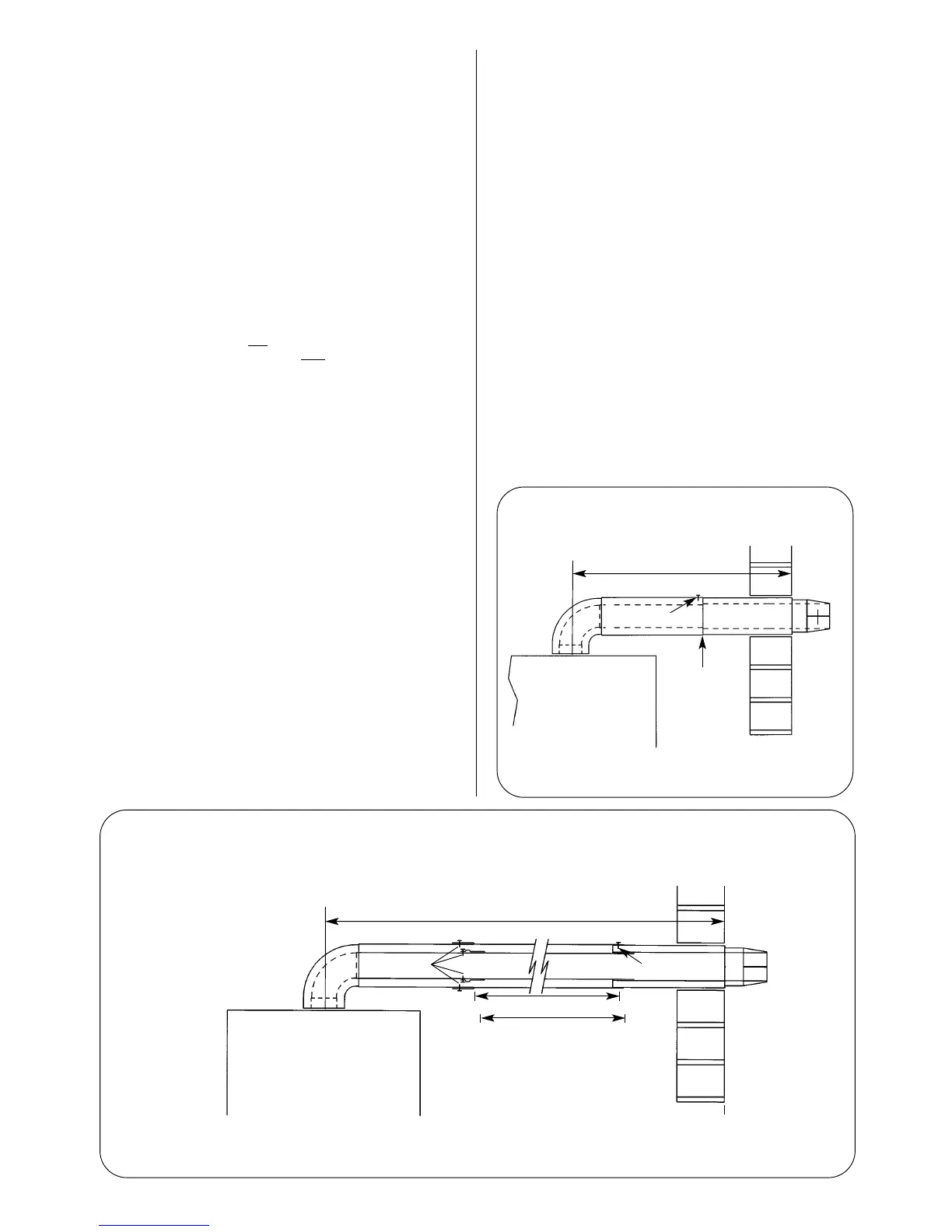

Fig.22. Flue assembly using extension kits.

L

Appliance casing

Fixing screws Fixing screw

Turret

assembly

Terminal

assembly

Ducts of equal length

Shorten first extension fitted

to the turret assembly if more

than one extension is fitted

Appliance casing

Fixing screw

Turret

assembly

Terminal

assembly

L

Telescopic

adjustment

Loading...

Loading...