21

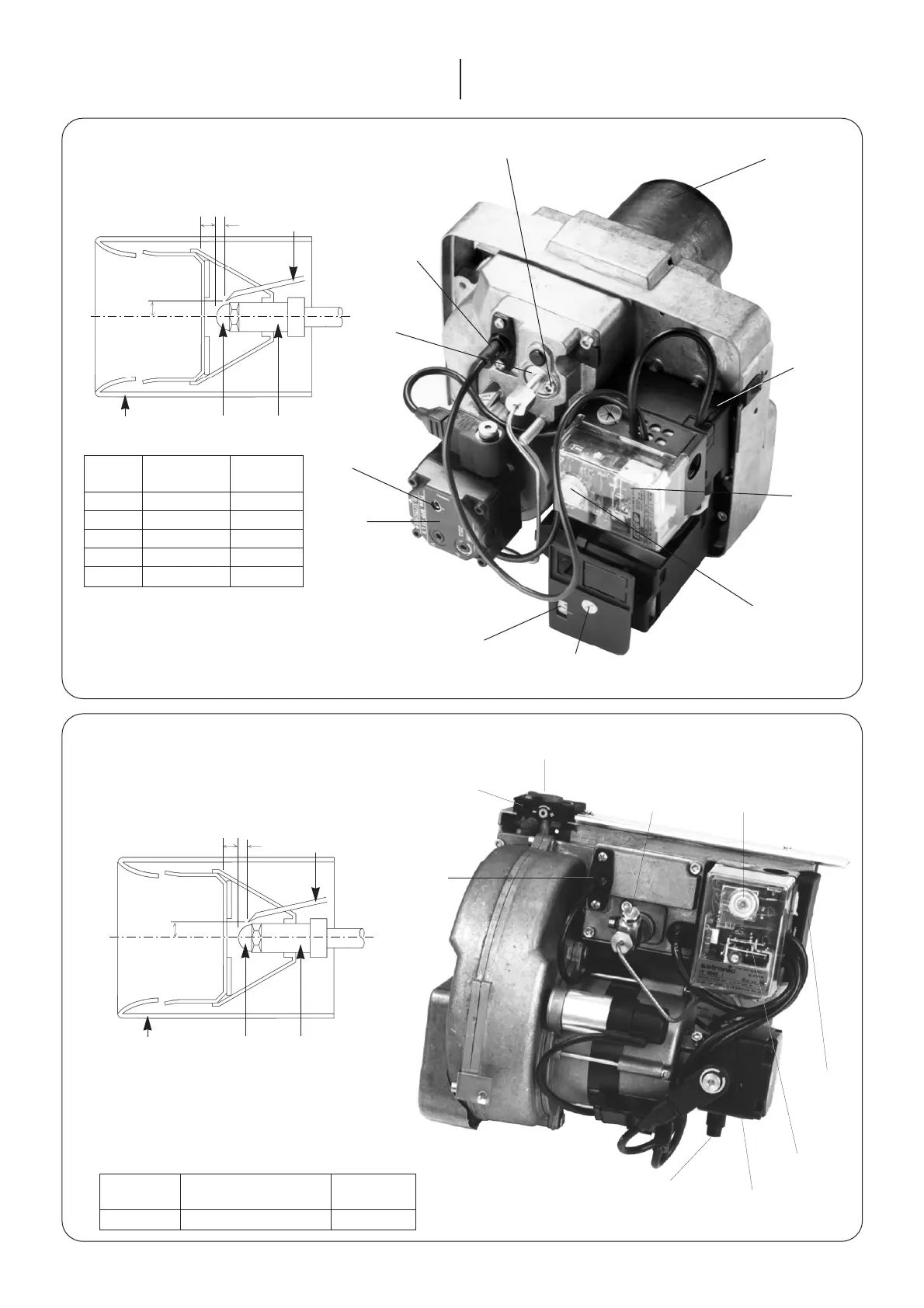

Fig. 22. Electro Oil Inter B11 Burner.

(20/25 model).

Combustion Head

Air control indicator

Photocell

Air adjustment screw

(4 mm hexagonal head)

Transformer

Control box

Oil pump

Pressure

adjustment

screw

Draught tube

Nozzle Nozzle block

Spark gap

3-3.5 mm

2 mm

10 mm

A

Lockout

reset button

Pressure

gauge port

Output

Combustion Head

Dimension

kW A

20/25 PL 10/4/24/10 x 78 mm 5 mm

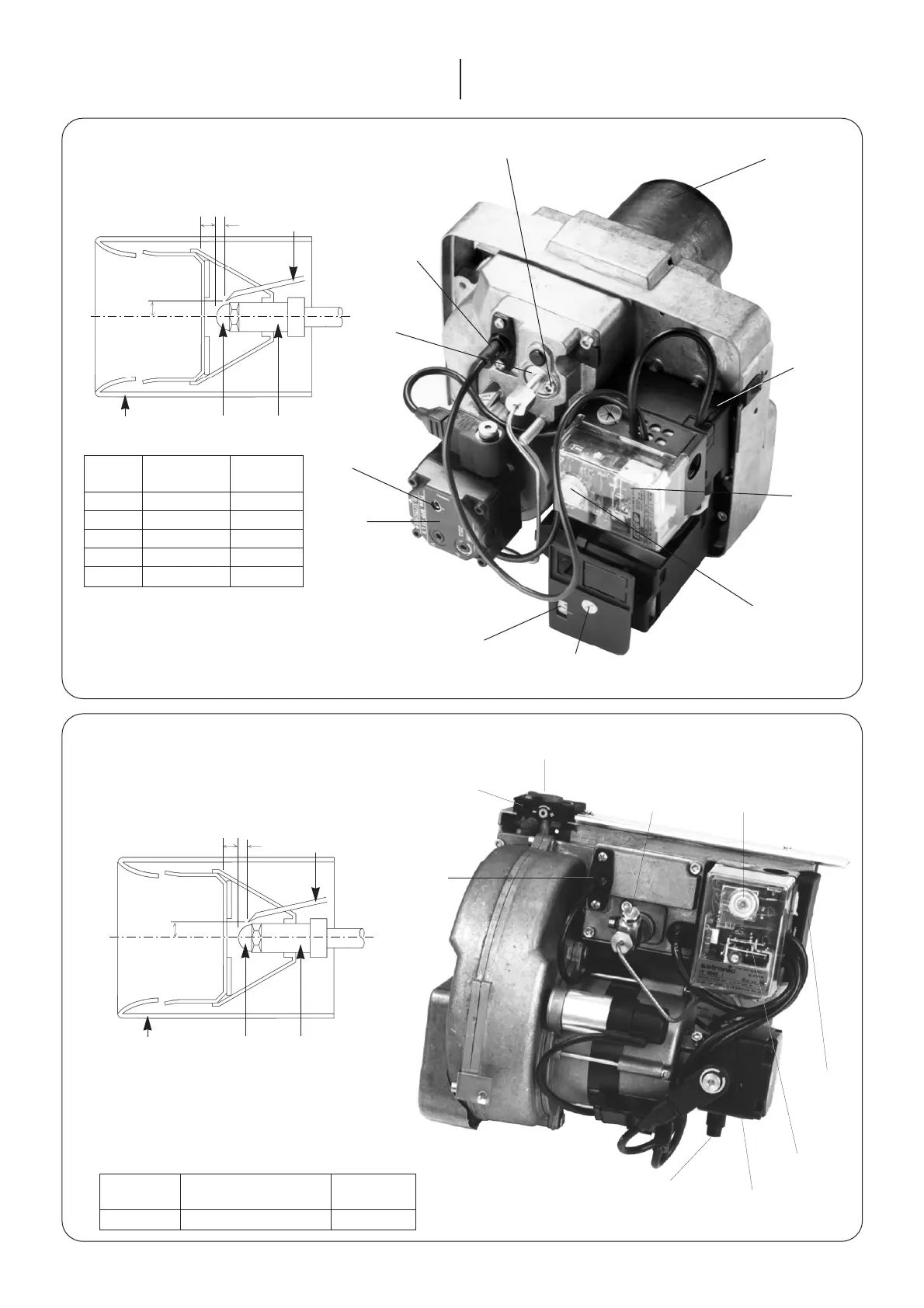

Fig. 21. Electro Oil Inter B9 Burner.

(12/14 and 15/19 models)

Combustion Head

Draught tube

Nozzle Nozzle block

Spark gap

2-2.5 mm

2 mm

10 mm

A

Combustion head

Locking screw

Transformer

Photocell

Control box

Lockout reset button

Air adjustment screw

(4mm hexagonal head)

Air control indicator

Oil pump

Pressure Adjustment

Screw

Adjusting

disc

Output Dimension

kW Head Type A

12

PL 6/7/21.5/10 3 mm

14 PL 6/7/21.5/10 5 mm

15 PL 6/7/21.5/10 3 mm

17 PL 6/7/21.5/10 5 mm

19 PL 6/7/21.5/10 5 mm

To adjust the nozzle position, undo the

locking screw located at the rear of the

nozzle line and rotate the adjusting

disc one turn anti-clockwise to move

forward by 1 mm.

2.20 Add a suitable proprietary corrosion inhibitor such as

Fernox or Sentinel. This will inhibit corrosion, protect the circu-

lating pump and valves reducing the possibility of "kettling"

noises resulting from deposits of scale and sludge in the boiler.

Refer to the product manufacturers instructions for further infor-

mation.

Loading...

Loading...