14

9.1 The appliance is suitable for connection to all conventional

indirect hot water systems utilising an indirect double feed

cylinder.

9.2 The flow and return sockets are located at the rear of the

appliance, two at high level (flow) and two at low level (return).

Connection of the flow and return sockets can either be made on

diagonally opposite sockets or on the same side of the boiler.

9.3 Provision has been made for locating the circulating pump

within the appliance cabinet. If so required, the socket located in

the top front of the boiler should be used and the flow pipe run

either side of the boiler (See Figs. 2 and 3).

9.4 There is no requirement for a system bypass.

9.5 The pressure jet burner fitted to the appliance has full

automatic control and hence there is no requirement for heat

leak radiators.

9.6 Any unused boiler tappings should be plugged prior to

filling. It should be noted that the flow tapping on the front of

the boiler requires plugging when not used.

9.7 The primary system should be flushed and treated in

accordance with the recommendations of BS 7593:1992 before

the system is handed over to the user.

9.8 The pump should be set in accordance with the heating load

requirements to give a flow and return differential temperature

of 11°C under full load conditions.

Open Vent Primary System.

(See Figs. 12 and 13).

The following points are for guidance only. The system

installation should be carried out in accordance with BS 5449:

Part 1.

1. Feed and Expansion System

The feed and expansion pipes must rise continuously from the

appliance and must be of the minimum diameter shown in Figs

12 and 13.

The cistern must be arranged to provide a minimum static head of

1 metre above the top of the highest point in the heating circuit.

2. Filling and Venting

Air in the appliance is expelled through the vent pipe or

dissipated into the system. Manual air vents should be fitted at

any high points in the system.

9. Heating and Hot Water System

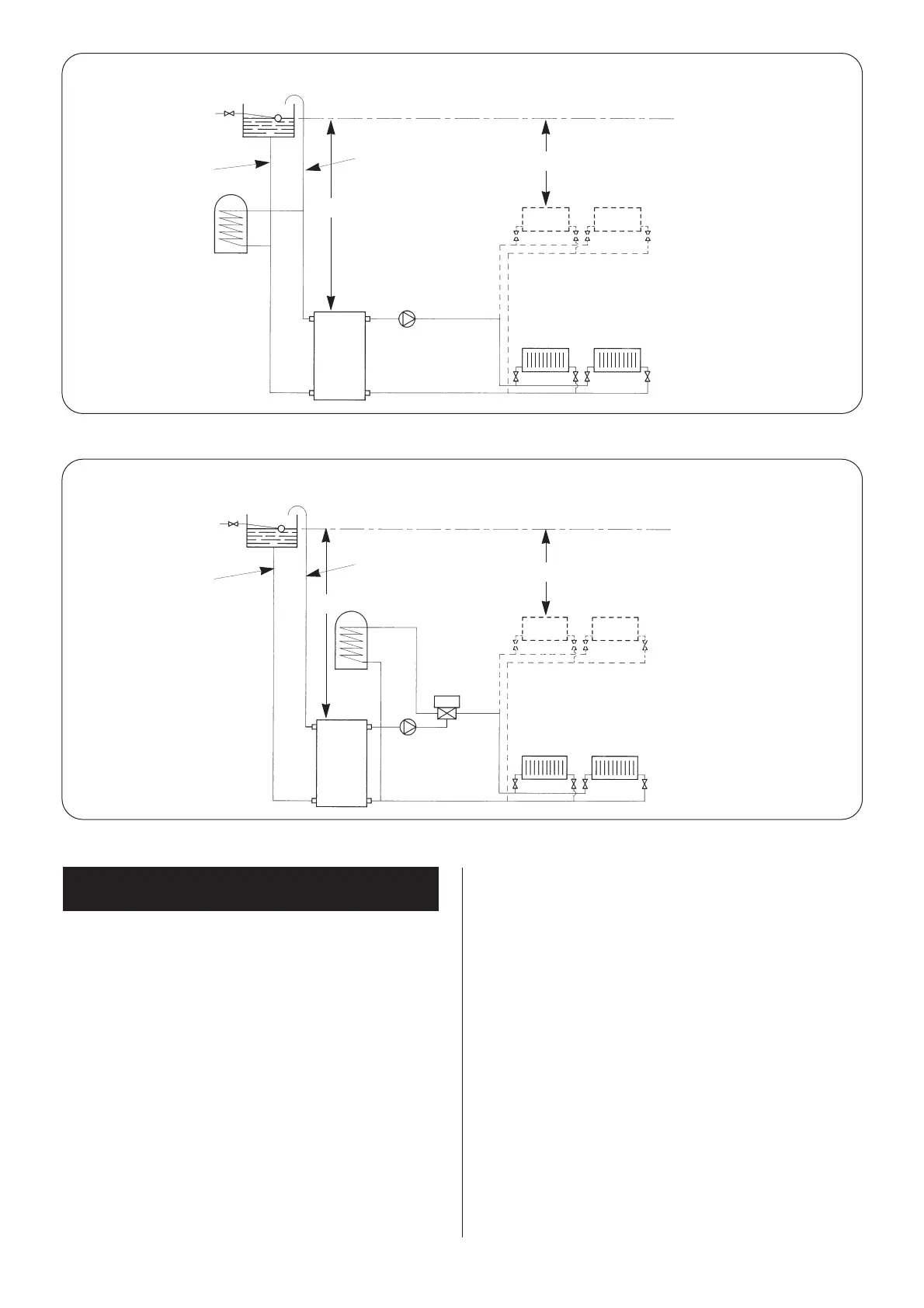

Fig. 12. Typical Open Vent Gravity Primary System.

Feed and

Vent Cistern

Primary cold

feed (15mm min.)

Primary cold

feed (15mm min.)

Heating vent

(22mm min.)

Heating vent

(22mm min.)

Boiler

Pump

Radiator

S.H. – Minimum static head 1m (3ft)

measured from the top surface of the

appliance or highest point in the

heating system to the water level in

the feed and expansion tank

N.B. A drain cock should be

installed at the lowest point

of the heating circuit

Domestic

hot water

cylinder

S.H.

S.H.

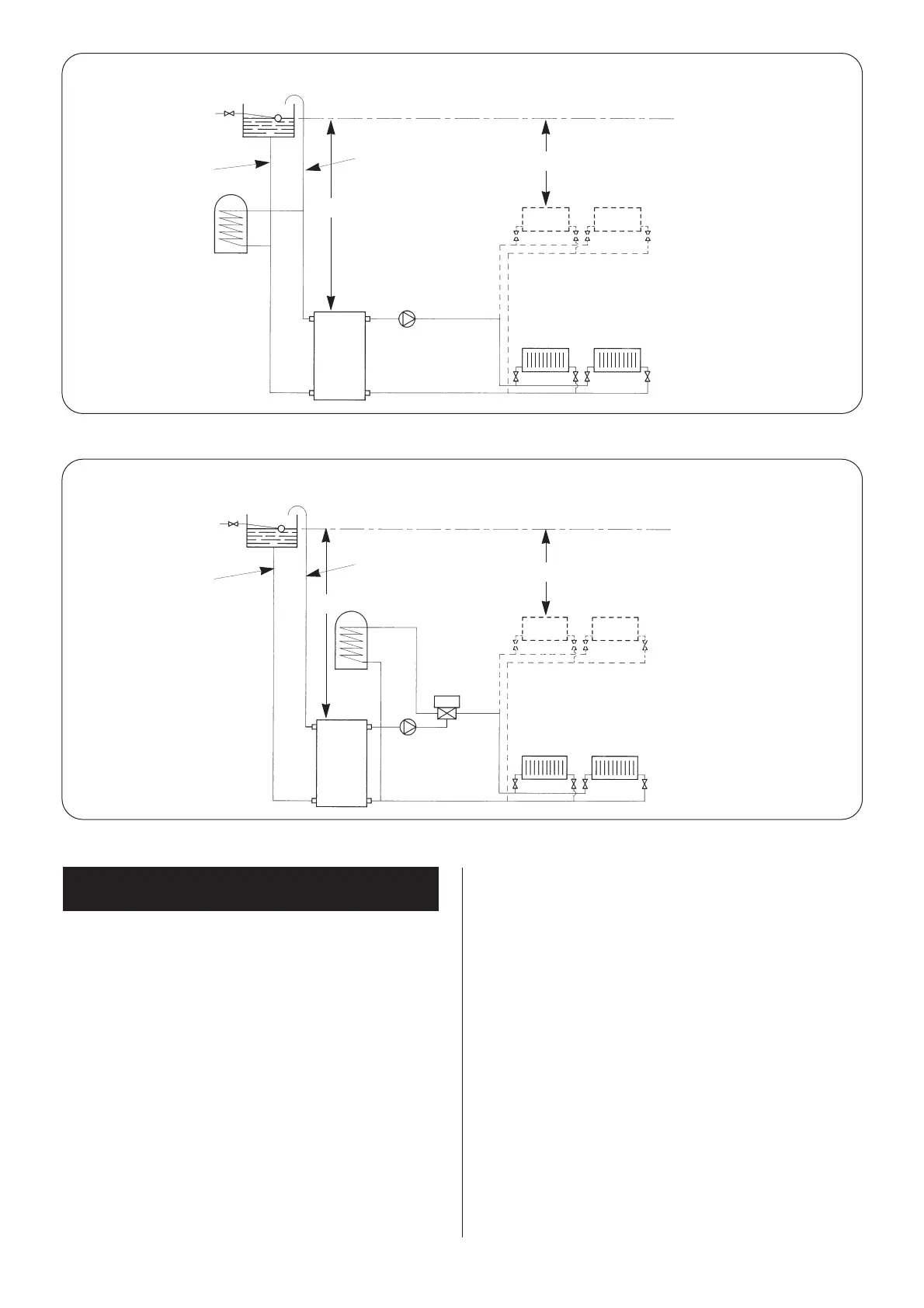

Fig. 13. Typical Open Vent Fully Pumped System (Honeywell ‘Y’ plan).

Feed and

Vent Cistern

Diverting

valve

Boiler

Pump

Radiator

S.H. – Minimum static head 1m (3ft)

measured from the top surface of the

appliance or highest point in the

heating system to the water level in

the feed and expansion tank

N.B. A drain cock should be

installed at the lowest point

of the heating circuit

Domestic hot

water cylinder

S.H.

S.H.

Loading...

Loading...