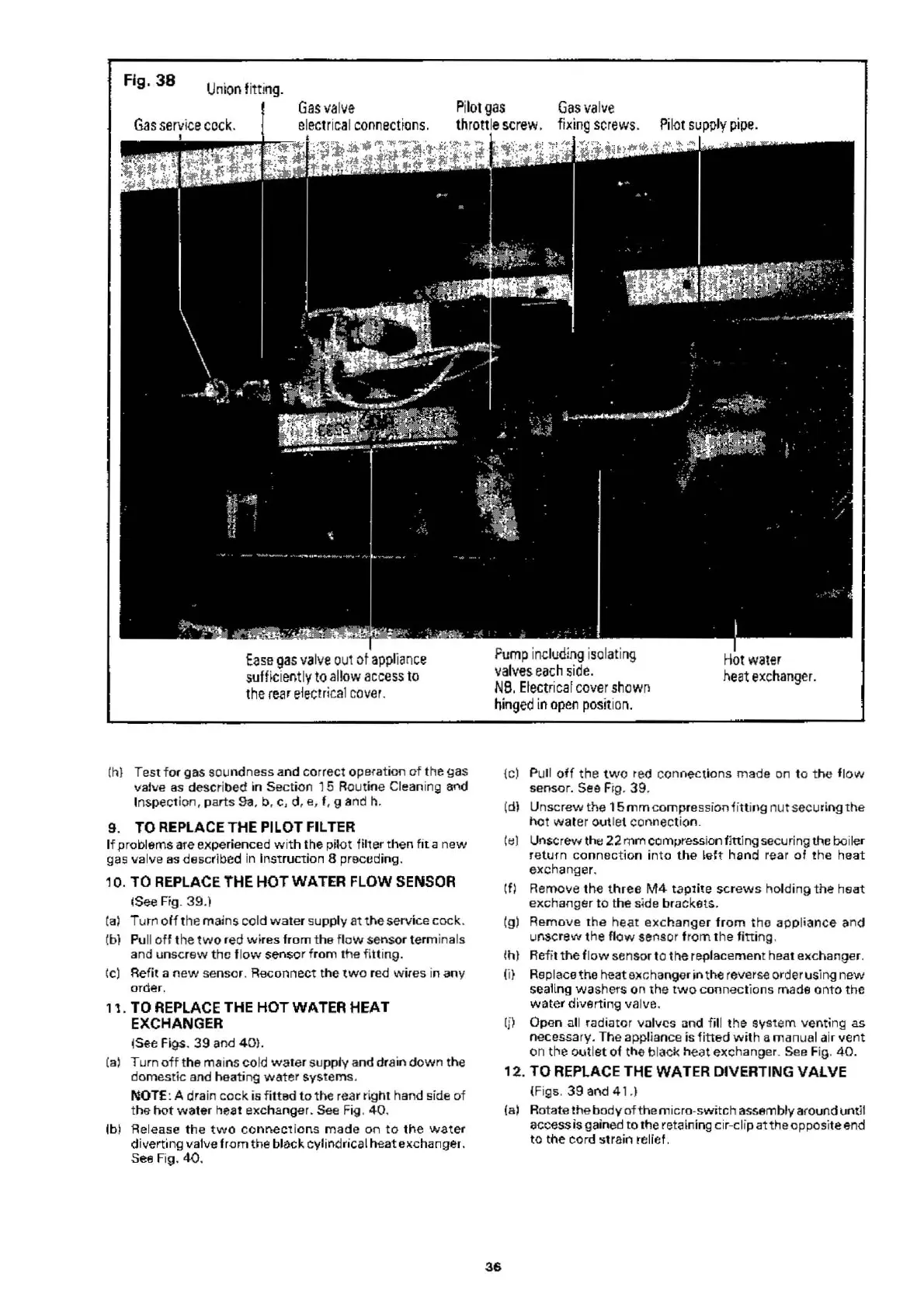

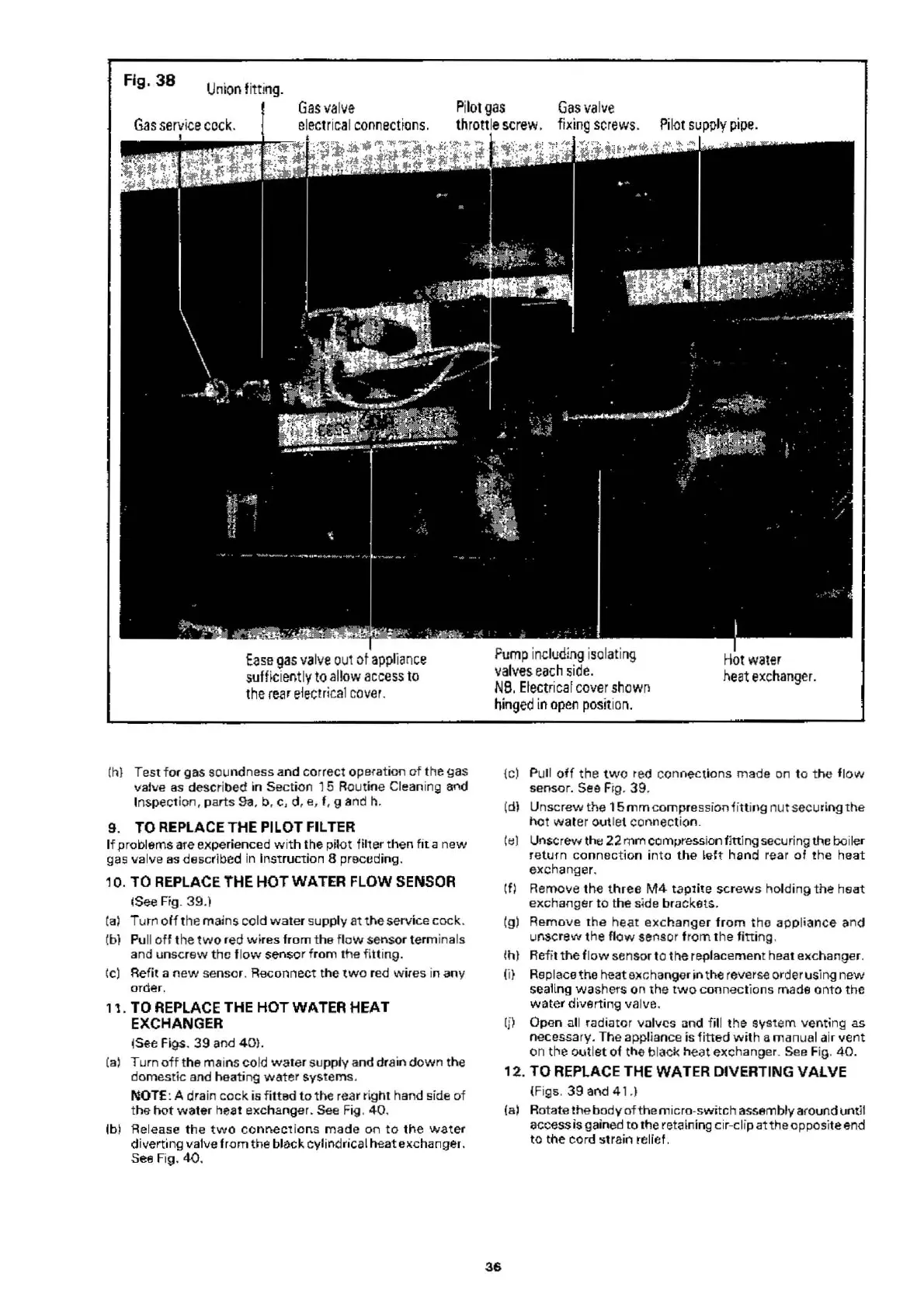

Fig

.

38

Union

fi

tt

i

ng.

Gas

va

l

ve

Pil

ot

gas

Gas val

ve

Ga

s se

rvice

cock

.

elec

t

ric

al

co

nn

ect

ions.

th

rottle s

crew.

fixing

sc

r

ews

. Pi

lo

t su

pp

ly p

ipe

.

tase

ga

s valve

out

of

app

l

iance

sufffci

ent

ly

to

al

l

ow

access

to

t

he

(ear electrical

co

ver

.

(h} Test f or

gas

soundness a

nd

correct

operat

i

on

of

the

gas

valve as described in

Sect

i

on

15

Ro

ut

i

ne

Cleaning and

Inspection, parts 9a, b, c, d, e, f, g and h.

9.

TO

REPLACE THE PILOT FILTER

If

prob

lems are experienced

wit

h the

pilot

filter then f

it

a

new

gas valve

as

descr

ibed in I

nst

ru

ction

8 preced

in

g.

10. TO REPLACE

THE

HOT

WATER

FLOW SENSOR

!See Fig.

39.)

[a)

Turn

off

the

mai

ns

cold

wate

r su

pp

ly

at

the service

cock.

(b)

Pu

ll

off

the

two

red

wires

from

the fl

ow

sensor terminals

and unsc

rew

the

fl

ow

se

n

sor

from

t

he

fi

tt

ing.

(C) Refit a

new

se

nsor

.

Reconnect

the

two

red wires in

any

order.

1

"1.

TO

REPLACE THE

HOT

WATER

HEAT

EXCHANGER

ISee Figs.

39

and 4

0)

.

(a)

Turn

off

the mains cold

wate

r supply and drain

down

the

d

om

estic

and heating

water

systems

.

NOTE

: A drain

cock

is f

it

te

d

to

the

rear

right

hand side

of

the

hot

wate

r heat e)(changer. See Fig .

40

.

(bl Release

the

two

co

n

nectio

ns

made

on

to

t

ne

water

dive

rting valve f

rom

the

bl

ack

cy

li

ndr

ical h

eat

exc

hanger.

Sea Fig.

40

.

P

um

p

in

cl

udin

g i

so

lati

ng

va

l

ves

each si

de.

H

ot

water

heat

exc

h

anger.

NB. E

lectrical

cover

sh

own

hing

ed

[n

op

en

posit

i

on.

36

{C)

Pull

off

the

tw

o red con

nect

i

ons

made

on to

the

f

low

sensor. See Fig.

39

.

(d) Unsc

rew

the

15

mm

co

mpre

ssion

ii

tt

i

ng

nut

securing

the

hot

wa

ter out let

connec

t

io

n.

(t:) Un

screw

the

2:2.

mm compression

fi

tt

ing securing the boiler

return

con

nectio

n

into

t

he

~ef

t

hand

rear

of

the h

eat

exchanger

.

(f) Remove

the

three

M4

taptite

sc

r

ews

ho

l

ding

the

h

eat

exchanger

to

the

side brackets.

(g)

Remove

the

heat

exc

hanger

fr

om

tho

appliance

and

unscrew the fl

ow

sensor f

rom

the

fi

tt

ing.

~h)

Refit

the

flow

sensor to the replacement heat exchanger.

(i)

Replace the heat

eJCc;

hanger

in

the rever

se

order using

new

sealing

wa

shers on the

two

c

on

nect

ions

ma

de

onto

the

wate

r d

iv

erting valve.

(j) Opon all radia

tor

vn

l

vcs

and fill

the

system

venting as

necessary.

The

appliance is 1itted

with

a

ma

nual air vent

on

the o

utlet

of the blacl< h

e<Jt

ex

changer. See F

ig

.

40.

12.

TO

REPLACE THE

WAT

ER DIVERTING

VA

l VE

(F

igs.

39

and

41

.)

{a)

Rotate

the

body

of

the

mi

cro-s

wi

tch assembly a(ound

unt

il

access is

ga

ined

to

the retaining

ei

r-e lip at

the

opposite and

to tne

cor

d strain reli

ef

.

Loading...

Loading...