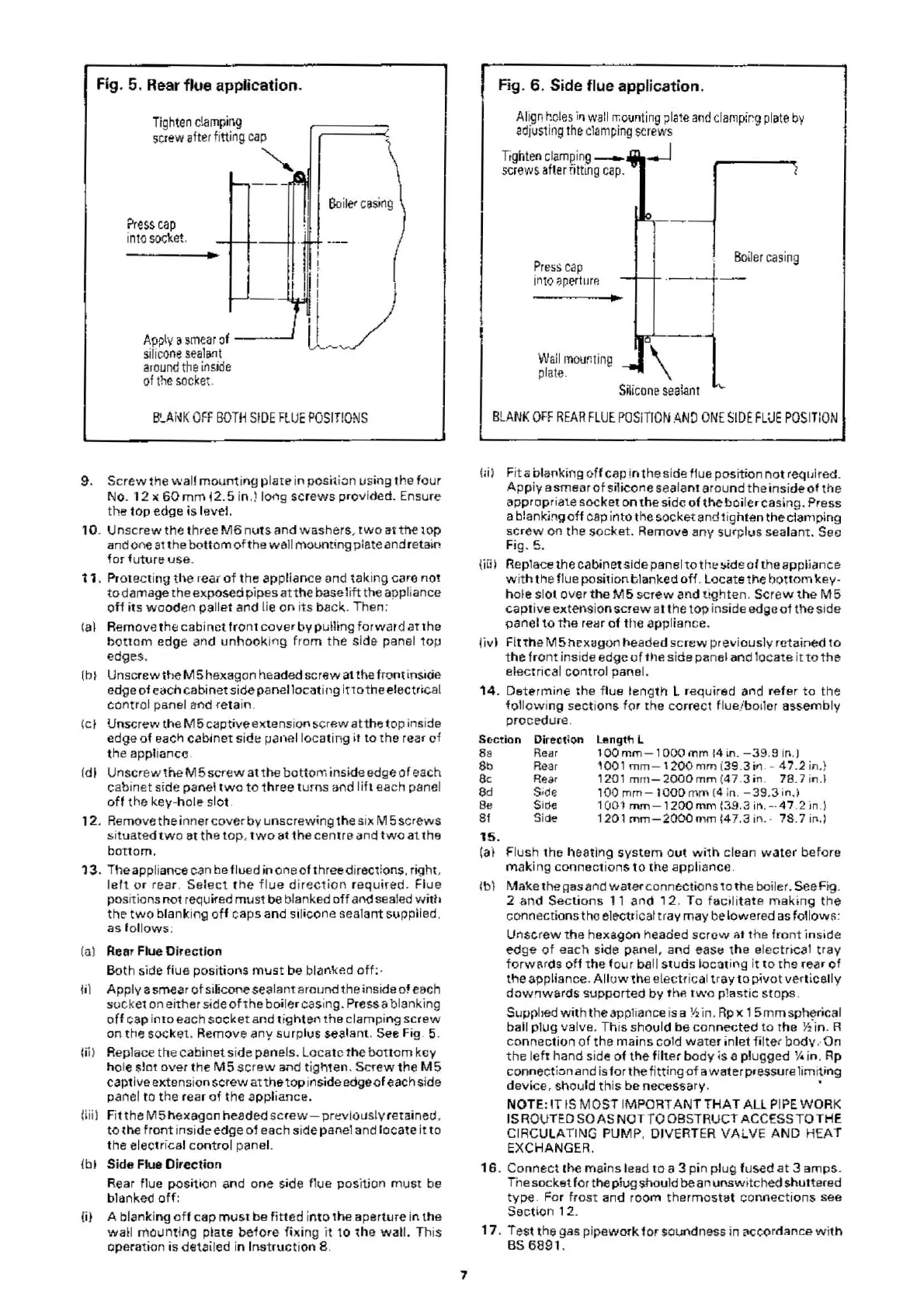

Fig. 5. Rear ftue application.

Trghten

clamp

il\g

screw

after fi

tt

i

ng

ca~

r

~

-

--

~

Press

cap

mto

socket.

! I

Ap~ya

M1earo

f

tl

_J

srll

c

one

sealant

around

the

ins

i

de

of

the

so

cke

t.

B'-A

i

..J

K

OFF

BOTH

S!

DE

FlUE

POSIT

i

ONS

9.

Screw

the

wall

mount

i

ng

pl

ate

in

posit

i

on

using the

four

No.

12

x

60

mm

t 2. 5 in.) long

screws

prov

ided. Ensure

the

top

ed

ge

is

level.

10

.

Unscrew

the

three M6

nu

ts

;~nd

washers

,

two

at

the

lOP

and one

at

the

bottom

of

the

wall

mounting plate and retain

for

•utur~

us

e.

11.

Protecting

the

r

eat

of

the

appliance and

tak

i

ng

care

not

to

damage

the

exposed pipes

at

the base

lift

the appliance

of

f its

wood

en

pallet

and lie

on

it

s b

ack

. Then:

Ia l Remove

th

El

cabi

net

fr

ont

c

over

by

pulling

forward

at

th

e

bo

ttom

edge

and

unhooki

r'l

g

from

the

side pan

el

top

edges.

(b

~

Unscrew

th

eM

5 hexagon headed

screw

at the front insi<ie

edge of each

cabinet

side panel

locating

ittothe

electrical

contr

ol panel and retain.

(c

t Unscrew the

M5

captive extensi

on

sc

rew

at the t

op

inside

edge

o1 each

cabinet

side panel

locating

it

to

the

rear

cf

th

e appliance.

(dl

Unscrew

theM

5screw

at

the

bottom

inside edge

of

each

cabi

net

si

de

panel

tw

o

to

t

hr

ee turns

and

l

ift

each panel

off

the

key-hole s

lot

.

12

. Remove

the

inner

cover

by

unscrewing the six M 5 s

cr

ews

si

tuat

ed

tw

o at

the

top

, t

wo

at

th

e

centro

i.ln

d

tw

o

at

the

bottom.

13

. The appliance can be flued

in

one

of

three directions. right,

lett

or

rear . Se

le

ct

t

he

flue

di

rec

t ion r

equired

. Flu e

positions

not

required

must

be

blanked

off

and

sealed

wi

th

the

two

blanking

of

f caps and sil

ico

ne sealant supplied.

as

f

ollows

:

(

o)

Rear Flue

Direction

Bot

h side fiue positions

must

be blar'lked

off:-

til Apply a smear

ot

sili

cof'e

seal

ant

around

the

in

side

of

each

socket on either side

oft

he

boile

r

ca

sing. Press a blanking

of

f cap

into

each

socket

and t

igh

ten t

he

clamping scr

ew

on

tt1e

socket. Remove

any

surp

lu

s sealant. See Fig. 5.

Iii) Replace the cabinet side panels. Locate

the

bottom

key

ho

le slot

over

the

M5

screw

ar1d

tigl"'1en.

Screw

the M 5

captive extension

screw

att

he

top

inside edge

of

each side

panel to

the

rear

oi

the a

pplian

ce.

(iii)

Fit

theM

5 h

exagon

headed scr

ew

-

previously

retained,

to

the

front

insi

de

edge

o1

each si

de

panel and

lo

cate

it

to

th

e elec

tr

ical

control

panel.

{b

~

Side Flue Direction

Rear flue

position

and o

ne

s

id

e flue position must be

blanked

off

:

lil

A blanki

ng

off

cap

must

be

fit

ted

in

to

the

aperture in the

wa

ll

mou

nti

ng

plate

before

fixing

it

10 1h

e

wall.

This

operation

is

detailed in I

nstr

u

ct

i

on

8.

7

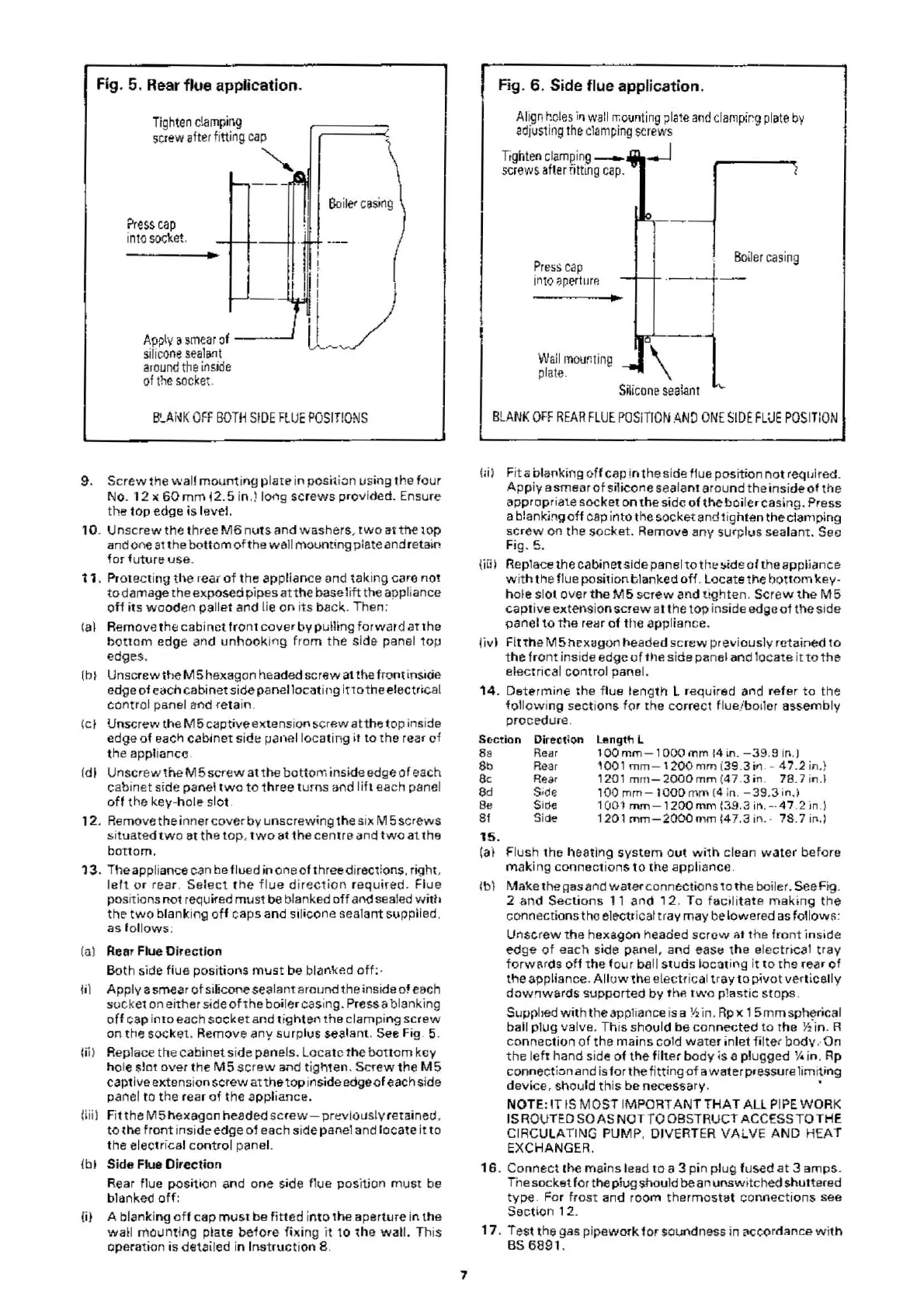

Fig.

6.

Side flue application.

Align

hcles

i11

wail

rr.o

;,rntin

g

;>la

te

and

cla

mp

ir.g

plilt~

by

adjus

ti

ng

t

he

c

lamping

screws

Tight

en cl

amping--

-.J

screws

afte

r

fitting

ca

p.

I

BaUer

ca

sing

Pr1:1ss

cap

in

t

oilpe

rtur

e

-

-~-

!

f

I

Wail

mount

i

ng

\

--

-1

plate.

sm

cone

sealant

BLANK

OFF

REAR

F

LUE

POSiTION

ANO

ONE

SIDE

FLUE

POSITION

(;i ) F

it

o blanking

off

cap

in

t

hesid~

f1ue

position

not

reqtJired.

App

iy a smear

ot

sil

ic

one

seala

nt

around

the

insi

de

of

the

appropriate

socket

on

the

side

of

the

boi

l

er

casing. Press

a

blanking

off

ca

p i

nto

tk

e socket and 1ighten

tile

clamping

screw

on

the

socket

. R

emov

e

any

surplus sealant. Sec

Fig.

5.

{Hi

I Replace the cabine• side panel

to

tb~:

~ids

of the appliance

with

th

e flue position blanked o

ff

. Loca

te

tf'\e

bo

ttom

key-

hole

sl

ot

over

the

M5

screw

and

tighte

n.

Screw

the

M5

captive

extens

ion

screw

ilt the

top

inside edge

of

ttle

si

de

pane

l

to

the

reHr

of

the appliance.

li

vl

Fi

tthe

M5hexagon

!'leaded scr

ew

pre11iously retained

to

t

he

front

i

ns

ide edge

uf

tile

si

de

panel

and

lo

cate

it

to

the

electrical control panel.

14

. Determine

th

e flue

length

l required and

refer

to

the

follow

i

ng

secti

ons

for

the

co

rr

ect

flue/boiler assembly

procedure.

So

c

tion

Ba

Direct;

on

Rei!r

Rear

Rea

r

Side

length

l

lOO

mm

- 1

000

mrn i4 in.

-39

.9 in.)

1001

mm

-

1200

mm

(39.3

if'l

.

--

47.2 in.)

1201

mrn-4000mm

(

47

.

3i

n.

78

.7

in

.J

100

rnrn - l OOOmm !4 in.

-39

.3 i

n.)

1001

mm

-

1200

mm

(3.9.3

in

. -

-4

7 .2 in.)

1201

rnm-2000mm

147.3

in

. -

78.7

in,)

Sb

8c

8d

Be

81

15

.

Si

cle

Si

de

(a

't Flush the heating

system

o

ut

wilh

clean

wate

r

before

mak

ing

connections

to

the

appliance.

lb

I

Mak

e the

~as

and

water

connections

to

th

e boiler. See Fig.

2

an

d

Sect

i

ons

11

and

12

.

To

f!icil

it ate

maki

ng

the

connections the electricat tray may be lowered

as

fo!lovv

~:

Unscrew

the

hexa

gon

headed

screw

at

the

front

inside

edge

of

each si

de

panel, and

e

a

s~

t

he

elec

trical

tray

f

orwar

ds

off

the

four

ball studs

locating

it

to

the

rear

of

the

applian

ce

.

Alluw

'h

e electrical

tray

to

pivot

vertLCelly

downwards

supported

by

th

e

tw

o

plast

ic

stops

.

Suppbed w

it

h the appliance is a

'1:!

in.

Rp

x 1 5

mm

sph~

ri

c;~

l

ball

plug

valve. This

sho

uld

be

connected

to

rhe

Y2

in

. R

co

nn

ect ion o f

the

mains cold

water

in

l

et

filter

body

..

On

the

left

hand side

of

the

fil

te

r

bo

dy

is

a plugged

'A

in

. Rp

connection and is

for

th

e fitting

of

a

wa

ter pressure limi

ting

devi

ce, s

ho

u

ld

this

be

necessary. •

NOTE: IT IS

MOST

IMPORT

ANT

THAT

ALL

PIPE

WORK

IS R

OU

TED SO

AS

NOT

TO OBSTRUCT

AC

CESS

TO

THE

CIRCULATING PUM

P,

DIVERTER

VALVE

AND

HEAT

EXCHANGER

.

16

. Connect the ma

ins

lead

to

a 3 pin pl

ug

fused at 3

amps

.

The socket for the plug shou

ld

be

an

un

s

wit

ched shuttered

typ

e. For

frost

and room

thermo

s

tet

con

n

ections

s

ee

Sec

ti

on

12

.

17

. Te

st

th

e gas

pi

pewo

rk

for

soundness in

coc

c

or

dance

wit

h

BS

6891

.

Loading...

Loading...