21

Manual Arc Welding

When put ‘welding mode selection switch’ on ‘arc welding’ and Dc/pulse select switch on DC position,

it can be used as manual arc welding.

Choose Parameter setting knob enter into welding current parameter setting to adjust welding current

and also can enter into pushing force current parameter setting to adjust pushing force current.

DC TIG Welding

When put welding mode selection switch on TIG welding and put DC/ pulse select switch on DC

position, Put Steps 2/4 option switch on step 2, it can be used as DC TIG Welding.

Choose Parameter setting knob enter into welding current parameter setting to adjust welding current

and also can enter into current increasing time parameter setting to adjust increasing time, enter into

current decreasing time parameter setting to adjust decreasing time.

Choose Parameter setting knob enter into Postflow Time parameter setting to adjust Postflow Time.

Choose Parameter setting knob enter into Preflow Time parameter setting to adjust Preflow Time.

DC Pulse TIG Welding

When put welding mode selection switch on TIG welding and put DC/pulse select switch on DC

position, Put Steps 2/4 option switch on step 2, it can be used as Pulse TIG Welding.

Choose Parameter setting knob enter into pulse welding current parameter setting to adjust Pulse

welding current.

Choose Parameter setting knob enter into Pulse background current parameter setting to adjust Pulse

background current.

Choose

Parameter setting knob enter into pulse frequency parameter setting to adjust pulse frequency.

Choose Parameter setting knob enter into duty cycle parameter setting to adjust duty cycle.

Choose Parameter setting knob enter into current increasing time parameter setting to adjust increasing

time.

Choose Parameter setting knob enter into current decreasing time parameter setting to adjust

decreasing time.

Choose Parameter setting knob enter into Post flow Time parameter setting to adjust Post flow Time.

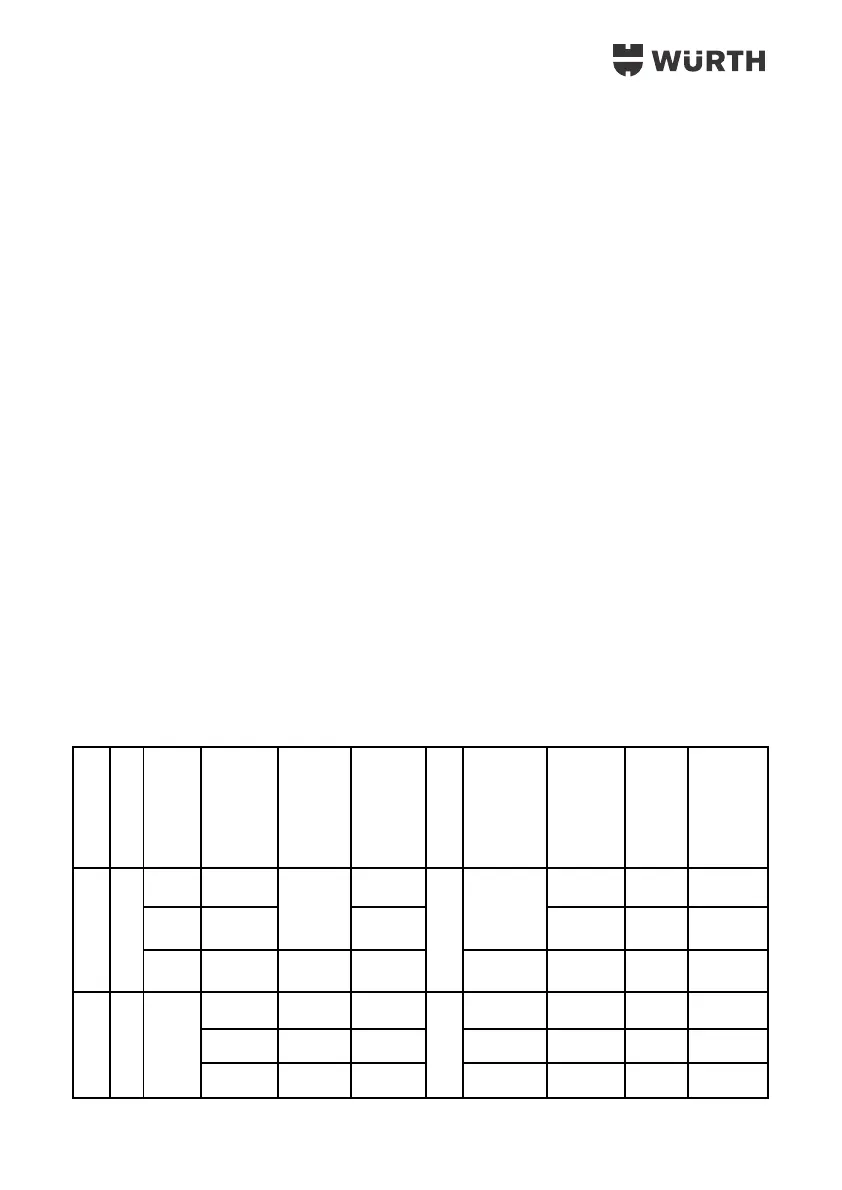

Welding regulations parameter table (only for reference)

Mode

Material Type

Designed Joint

Work

Thickness

(mm)

Wire Dia

Φ

(mm)

Welding

Current

(A)

Polarity

Argon

Flow

(dm

3

/min)

Tungsten

Stick Dia

Φ

(mm)

Angle

Top Dia

Φ

(mm)

DC

Stainless Steel

Vertical

Joint

1.6

~

3.0

1.6

~

2.5

50

~

90

DC Positive

8

~

12

1.0

12

~

20° 0.12

~

0.25

V

groove

>3.0

~

6.0 70

~

120

1.6

25

~

30° 0.50

~

0.75

X

groove

>6.0

~

12 2.5

~

3.2 100

~

150 10

~

14

2.4

35

~

45° 0.75

~

1.10

Arc weelding

Carbon steel

Joint

≤ 4 3.2

160

~

210

/ / / /

4

~

12 3

~

4 210

~

270

/ / / /

>12 ≥ 4

260

~

300

/ / / /

Loading...

Loading...