23

Common faults and solving methods

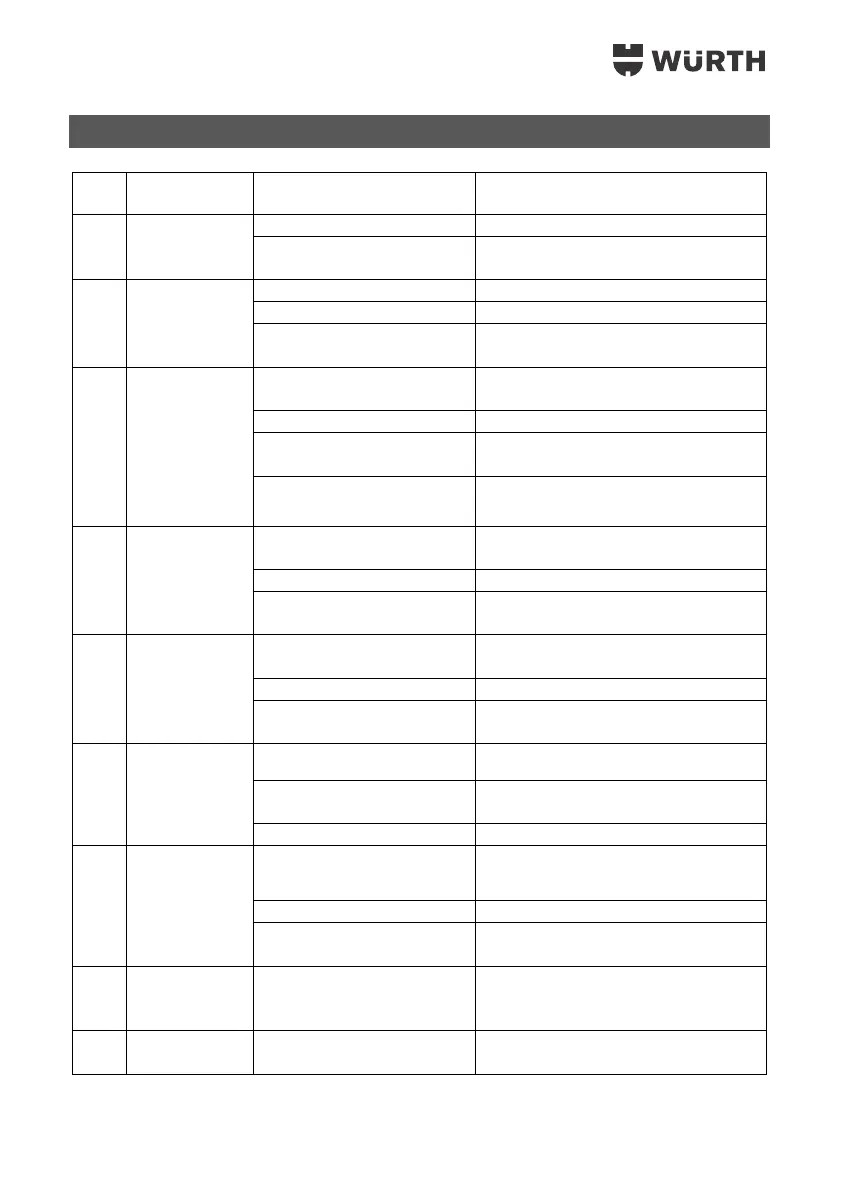

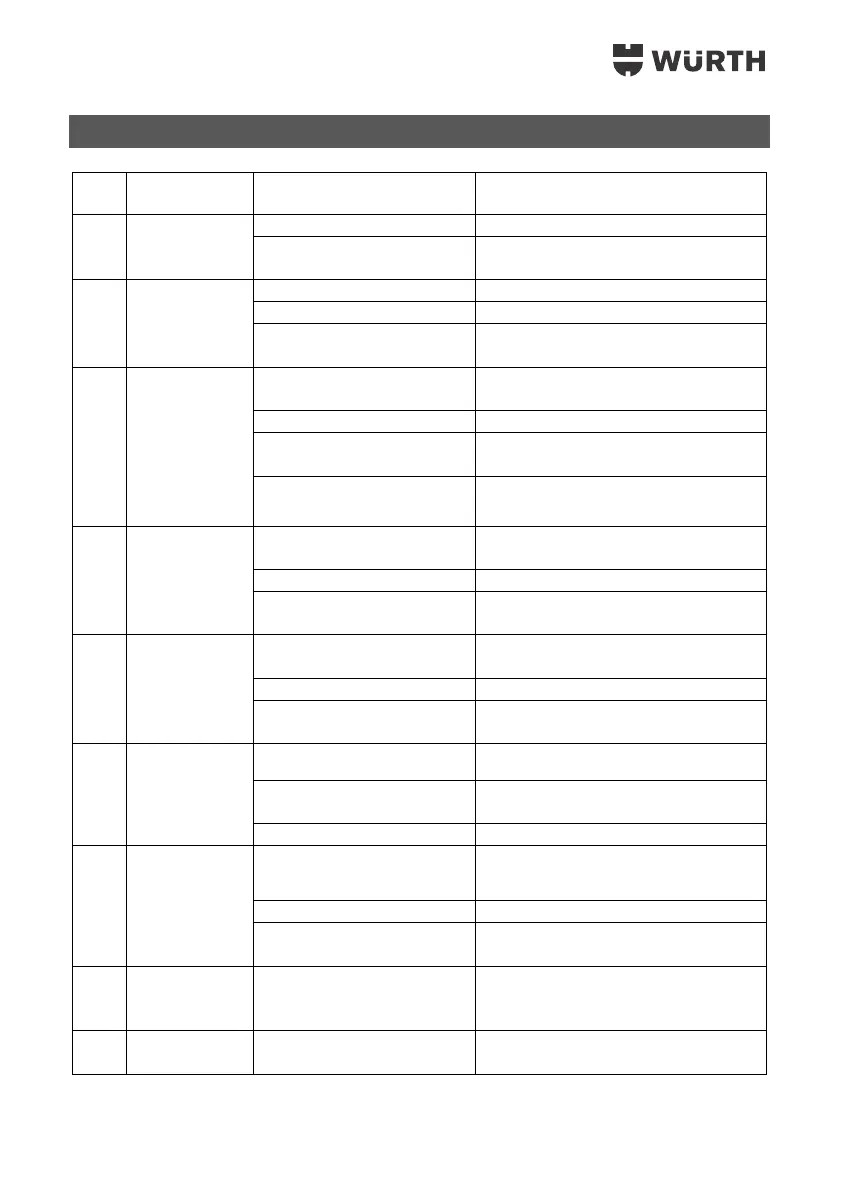

No. Breakdown Analysis Solutions

1

Cooling fan

Not work

Cooling fan broken Replace the fan

Cable broken/fallen off Find the disconnected wire and

Connect reliably

2

No piloting

high frequency

Torch switch broken Replace the torch

Main PC board broken Replace the PC board

Cable broken/fallen off Find the disconnected wire and

Connect reliably

3

No Argon

output

No Argon input Check the flow meter and resume

supplying gas to the welder

Main PC board broken Replace the PC board

Electromagnetism Valve

broken

Change the electromagnetism valve

Gas path blocked Clear the eyewinker and dredge the

gas path

4

Protection

Indicator On

Overheat inside the machine Become normal after the inside

temperature reduced

Thermal relay broken Replace the thermal rela

Over/Lack voltage more

Than 15%

Become normal after voltage o

5

Panel knob not

adjustable

Relevant potentiometer

broken

Replace the potentiometer

Main PC board broken Replace the PC board

Cable broken/fallen off Find the disconnected wire and

Connect reliably

6

No display on

the AMP meter

Digital Amp meter broken Change the meter

Cable broken/fallen off Find the disconnected wire and

Connect reliably

Main PC board broken Replace the PC board

7

Arc piloting not

smooth

rong connection between

torch and welder

Check and correct according the

manual

rgon not pure Use 99.99% pure Argon

Tungsten electrode or pin

broken

Use qualified Tungsten electrode

8 Power trip

First turning on after power

long time (2days more) off

Not fault, trip caused by the charging

filter capacitor in the main board,

return on the power switch

9 Others

Please contact with the

supplier/manufactuer

Loading...

Loading...