VESDA VLF-500-UL 7Ed Product Guide VESDA

44 www.xtralis.com

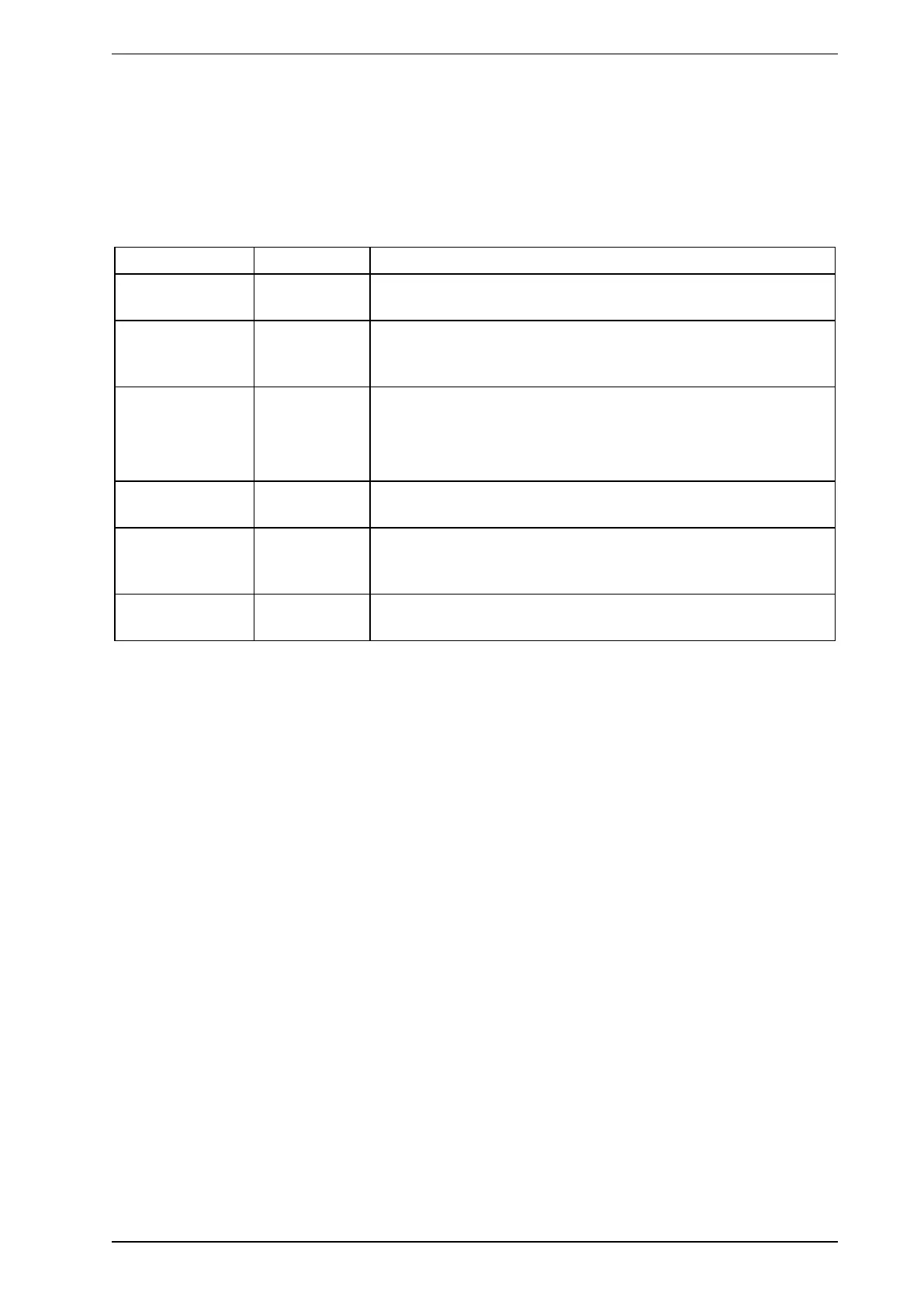

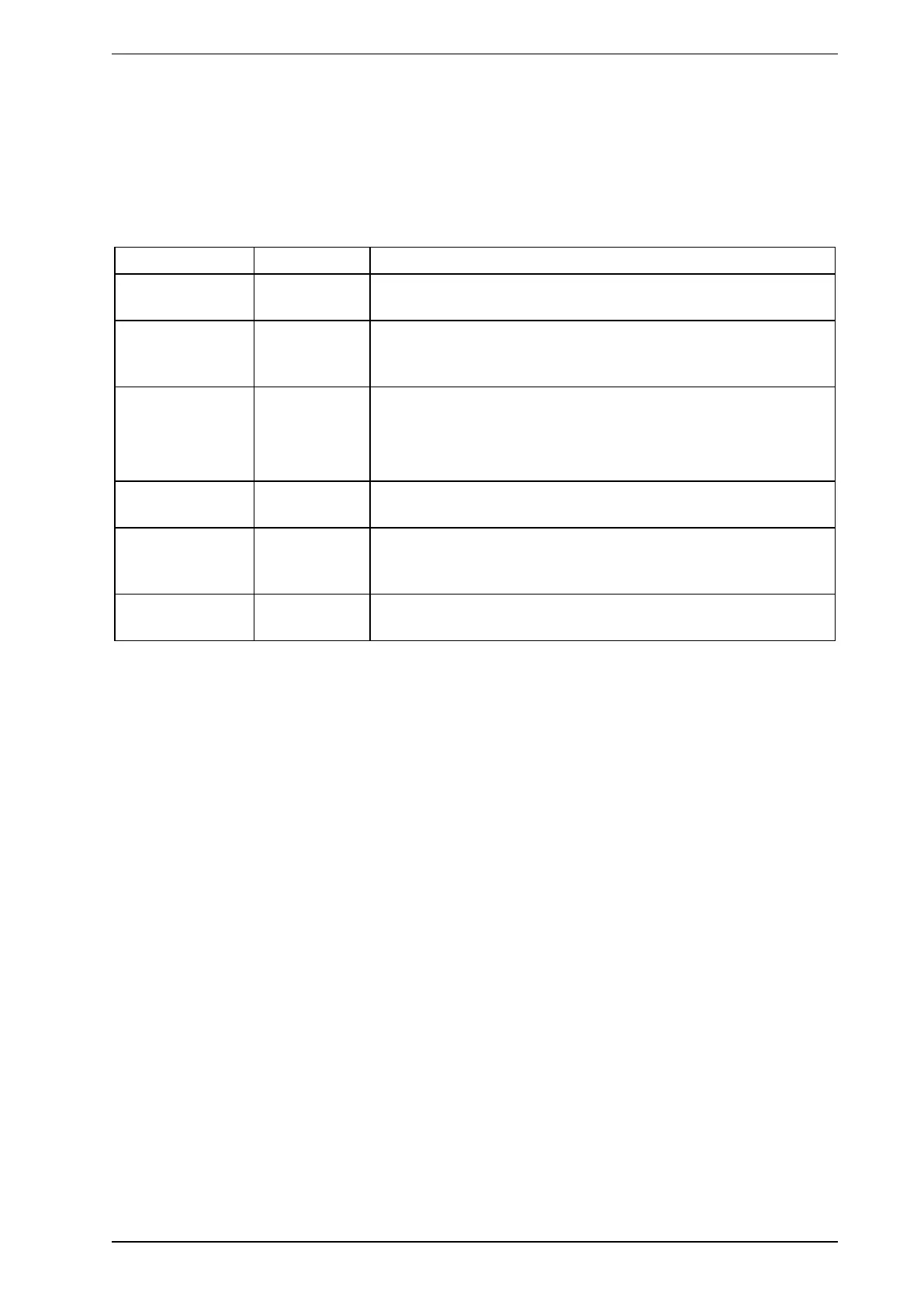

9.2 Maintenance Schedule

To maintain the VESDA VLF-500-UL in peak working order follow the maintenance standards for your region

and where no recommended standard exists see the table below. Please note, for environments that

experience high levels of contamination, the frequency of maintenance will need to be increased.

Maintenance should be conducted by a qualified service contractor.

Action Frequency Details

Check pipe

network

6 monthly Check pipe connections to ensure all pipe runs are intact and that

pipe supports and joints are firm.

Airflow Yearly Check air flow via Xtralis VSC software. Compare the current

reading with previous reading to determine if the flow rate has

reduced.

Smoke test Yearly Conduct smoke tests and verify detector performance (refer to the

VESDA System Design Manual).

Compare response times with those previously recorded and

investigate any discrepancies.

Check power

supplies

Yearly Test in accordance with suppliers instructions.

Filter replacement 2 Yearly Recommended change out period. The filter status can be checked

via Xtralis VSC software. Depending on the environment, the filter

may require more frequent checking.

Clean sampling

holes

As necessary If frequent low flow faults occur clean the sampling pipe network by

back flushing (refer to the VESDA System Design Manual).

Table 9-1: Maintenance schedule

Loading...

Loading...