6

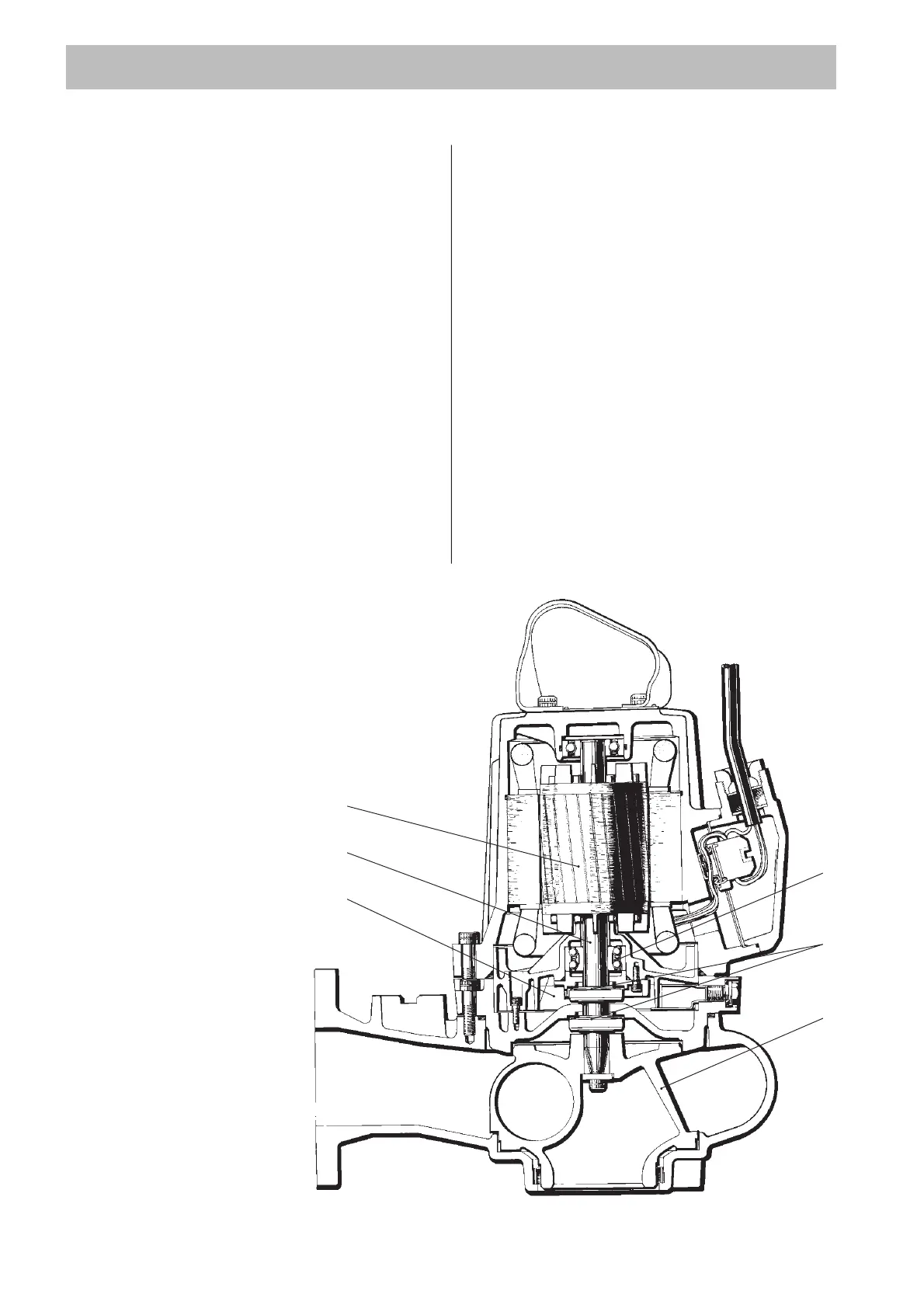

GENERAL DESIGN OF A FLYGT PUMP

Design

The pump is a submersible, electric motor-driven

product.

1. Impeller

The pump is available with a wide range of impellers

for different applications and capacities.

2. Shaft seals

The pump has two mechanical face seals – one inner

and one outer, with an intermediate oil housing.

3. Shaft

The shaft is delivered with the rotor as an integral part.

Shaft material: stainless steel.

4. Bearings

The support bearing of the rotor consists of a single-

row ball bearing.

The main bearing of the rotor consists of a two-row

angular contact ball bearing.

5. Oil housing

The oil lubricates and cools the seals and acts as a

buffer between the pump housing and the electric

motor.

6. Motor

Squirrel-cage 1-phase or 3-phase induction motor for

50 Hz or 60 Hz.

The motor can be started by direct on-line or star-delta

starting.

The motor can be run continuously or intermittently

with a maximum of 30 evenly spaced starts per hour.

Flygt motors are tested in accordance with IEC 34-1.

The stator is insulated in accordance with class H

(180°C, 360°F). The motor is designed to deliver its

rated output at ± 5% variation from the rated voltage.

Without overheating the motor, ± 10% variation from

the rated voltage can be accepted provided that the

motor does not run continuously at full load. The

motor is designed to operate at a voltage imbalance

of up to 2% between the phases.

Monitoring equipment

The stator incorporates thermal contacts connected in

series.

The pump can be equipped with sensors for sensing

water in the oil* and/or stator housing.

*Not applicable to Ex-approved pumps.

4

2

1

6

3

5

Loading...

Loading...