Frame, suspension and final drive 6*27

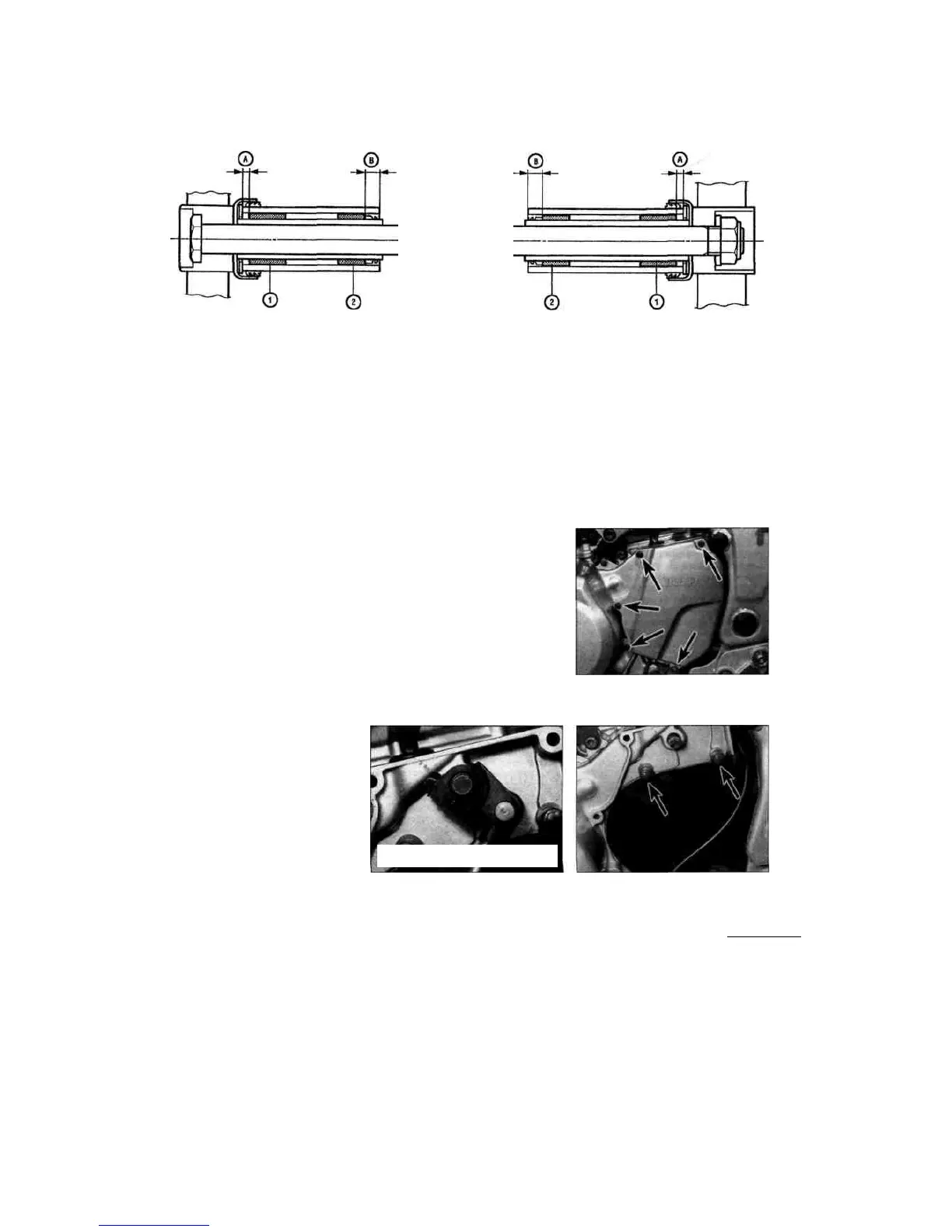

14.8 Swingarm bearing (1) and bush (2) installed depth

A 4 mm B 8 mm

in the Reference section for details of using a

drawbolt tool or bearing extractor with slide-

hammer attachment to remove the bearings and

bushes and install new ones. When installing the

new components note that they must be

positioned to a specific depth in the swingarm

housings (see illustration).

9 Measure the length of each bearing spacer

and the thickness of each washer and

compare them to the specifications, renewing

any component that is worn. Note: Worn

components will increase swingarm sidepiay.

10 Although it is possible to measure the

swingarm sidepiay with all components

assembled on the bike it is preferably to

calculate sidepiay by direct measurement of

the individual components. Done this way,

you will be able to install any shims required

as the swingarm is refitted. You will need a

vernier gauge to do this accurately. Measure

the width of the swingarm mounting boss on

the engine and call this dimension A. Record

the lengths of the two spacers measured in

Step 9 as dimensions B and C. Now measure

the overall length of the swingarm (from the

outside of one bearing housing to the outside

of the other) and record this as dimension D.

Record the thicknesses of the two washers

(added together) measured in Step 9 and

record this as dimension E. Compute

swingarm sidepiay by subtracting the

swingarm width and washer thicknesses from

the boss width and spacer lengths, thus:

Sidepiay = (A + B + C) - (D + E)

If the sidepiay is within the limit of 0.4 to 0.7 mm

no shims are required. If sidepiay exceeds 0.7

mm, fit one or two shims as required to bring

sidepiay within the specified limit. Shims are

available in 0.3 mm thicknesses. The shims

should be fitted between the cap and washer; if

two shims are required fit one on each side,

whereas if only one shim is required fit this on

the right-hand side.

11 Press the grease seals into their locations

in each side of the swingarm bearing

housings, renewing them if they are damaged or

deteriorated.

12 Lubricate the bearings, bushes and spacers

with lithium-based grease. Do not forget to install

the bearing spacer between the bearings in the

swingarm. Install the washers, shims (where

fitted) and caps on the outer ends of the

swingarm.

15 Drive chain - removal,

cleaning and installation

Endless type chain

Note: An endless chain has no riveted (soft) link -

all links and pins are the same. The chain fitted as

original equipment and supplied as a spare part

from Yamaha dealers is of the endless type.

Warning: NEVER install a drive

chain which uses a clip-type master

(split) link.

Removal

1 Remove the swingarm (see Section 13). Note

that if the front sprocket is being removed, the

sprocket nut should be slackened before

removing the swingarm, so that the rear brake

can be used so stop the sprocket turning (see

Section 16).

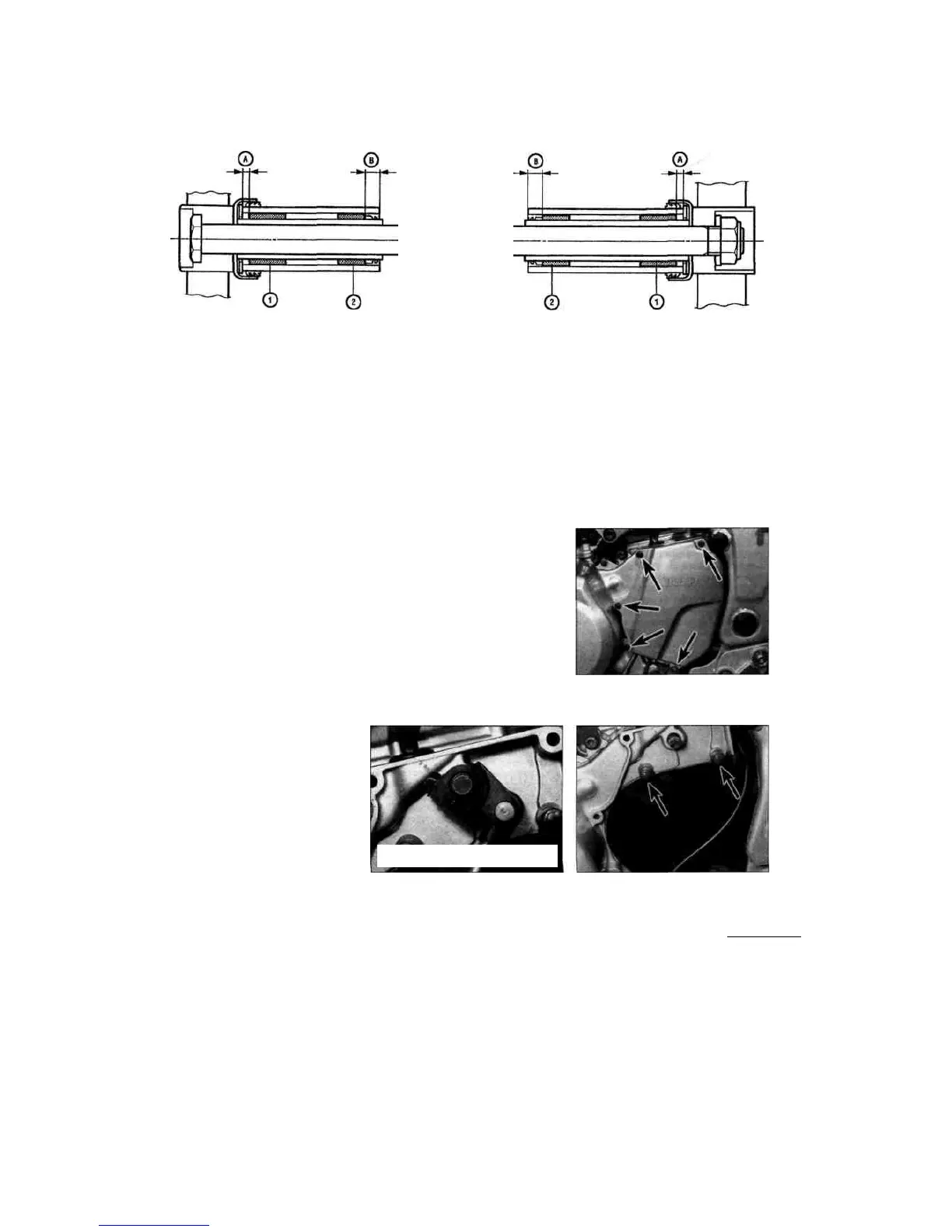

2 On TDM and XTZ models, unscrew the bolts

securing the outer front sprocket cover and

remove the cover (see illustration). Unscrew the

gearchange lever linkage arm pinchbolt and

remove the arm from the shaft, noting the

alignment of the punch mark with the slit in the

clamp (see illustration). If no mark is visible,

make your own before removing the arm so that

it can be correctly aligned with the shaft on

installation. Unscrew the bolts securing the inner

sprocket cover, on TDM models noting the clip

secured by the top rear bolt, and remove the

cover (see illustration).

3 On TRX models, unscrew the gearchange

15.2a Unscrew the bolts (arrowed) and

remove the cover

15.2c Unscrew the bolts (arrowed) and

remove the inner cover

6

Staned by Stalker

Loading...

Loading...