130

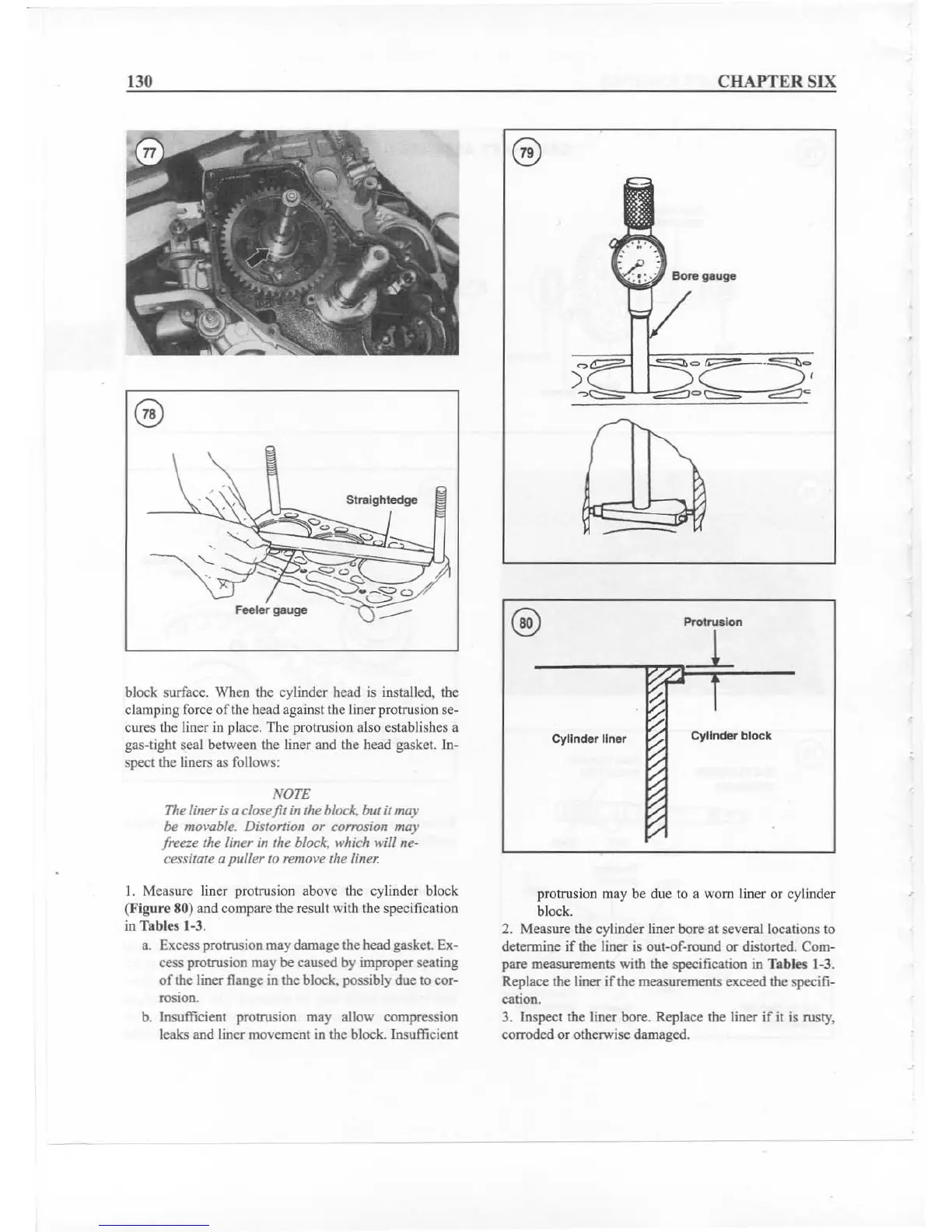

Straig

htedge

block surface. When the cylinder head is installed, the

clamping force

of

the head against the liner protrusion se-

cures the liner in place. The protrusion also establishes a

gas-tight seal between the liner and the head gasket. In-

spectthe liners as follows:

NOTE

The liner isa

close

fi t in the block, but it may

be movable. Distortion or corrosion may

freeze the liner in the block, which will ne-

cess itate a

puller

to remove the liner:

Cylinder

lin

er

CHAPTE R SIX

Bore gauge

Prol

l1J

slon

~

~F-"

i

c;::

~

~ Cylinder block

~

E::

~

~

V

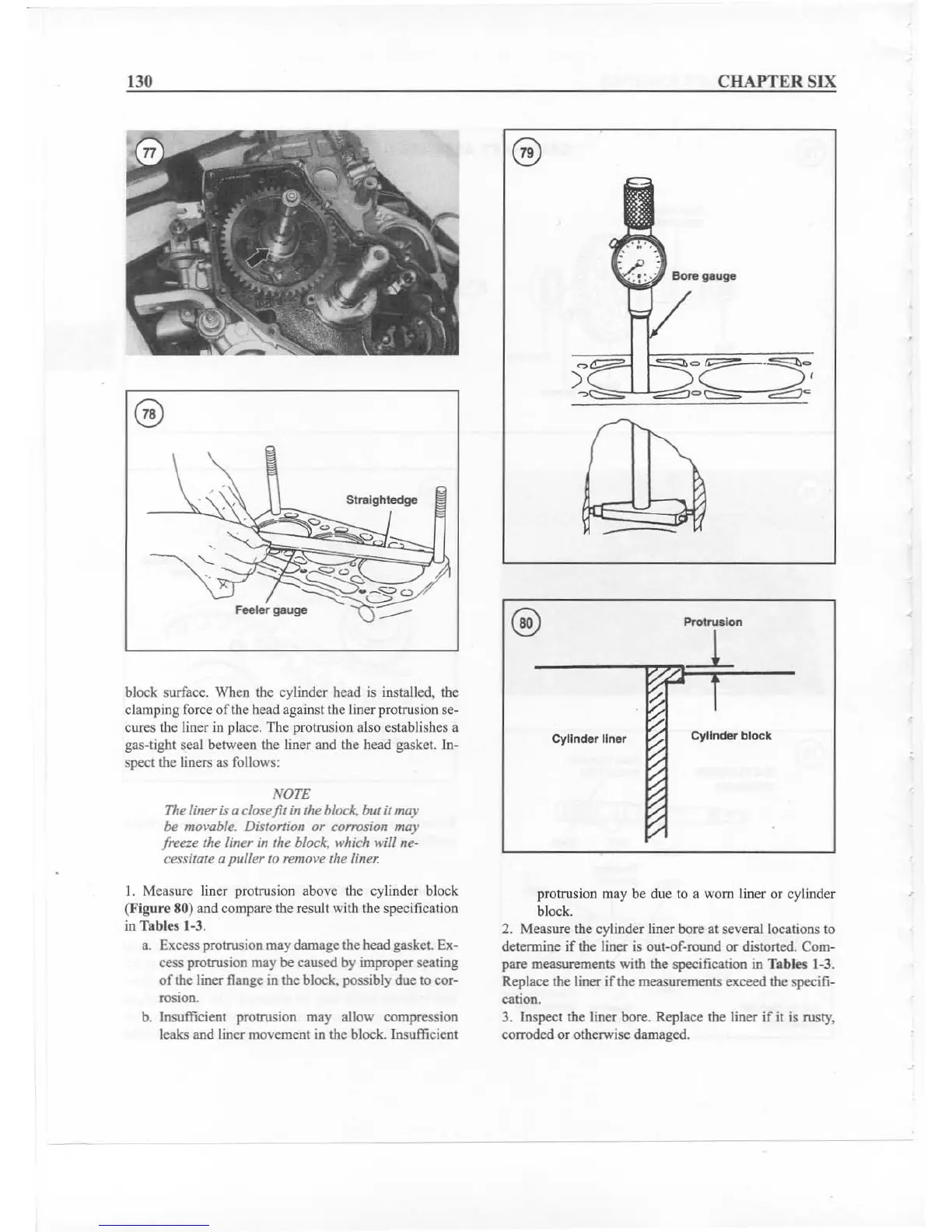

1. Measure liner protrusion above the cylinder block

(Figure SO)and compare the result with the specification

in Tab les 1-3.

a. Excess protrusion may damage the head gasket. Ex-

cess protrusion may

becaused by improper seating

of

the liner flange in the block. possibly due to cor-

rosion.

b. Insufficient protrusion may allow compression

leaks and liner movement in the block. Insufficient

protrusion may be due to a worn liner or cylinder

block.

2. Measure the cylinder liner bore at several locations to

determine

if

the liner is out

-of

-round or distorted. Com-

pare measurements with the

specification in Tables 1-3.

Replace the liner if the measurements exceed the

specifi-

cation.

3. Inspect the liner bore. Replace the liner if it is rusty.

corroded or otherwise damaged.

Loading...

Loading...