MUL

TIC

YLIN DER

ENG

INES

8

A

127

Inter-mediate

'l

ain Bearing

6

Width

I. Remove the intermediate bearing housing bolts

(Fi~

ure 68).

2. Separate the intermediate bearing housing halves from

the crank shaft.

3. Inspect the bearings for excessive wear and damage.

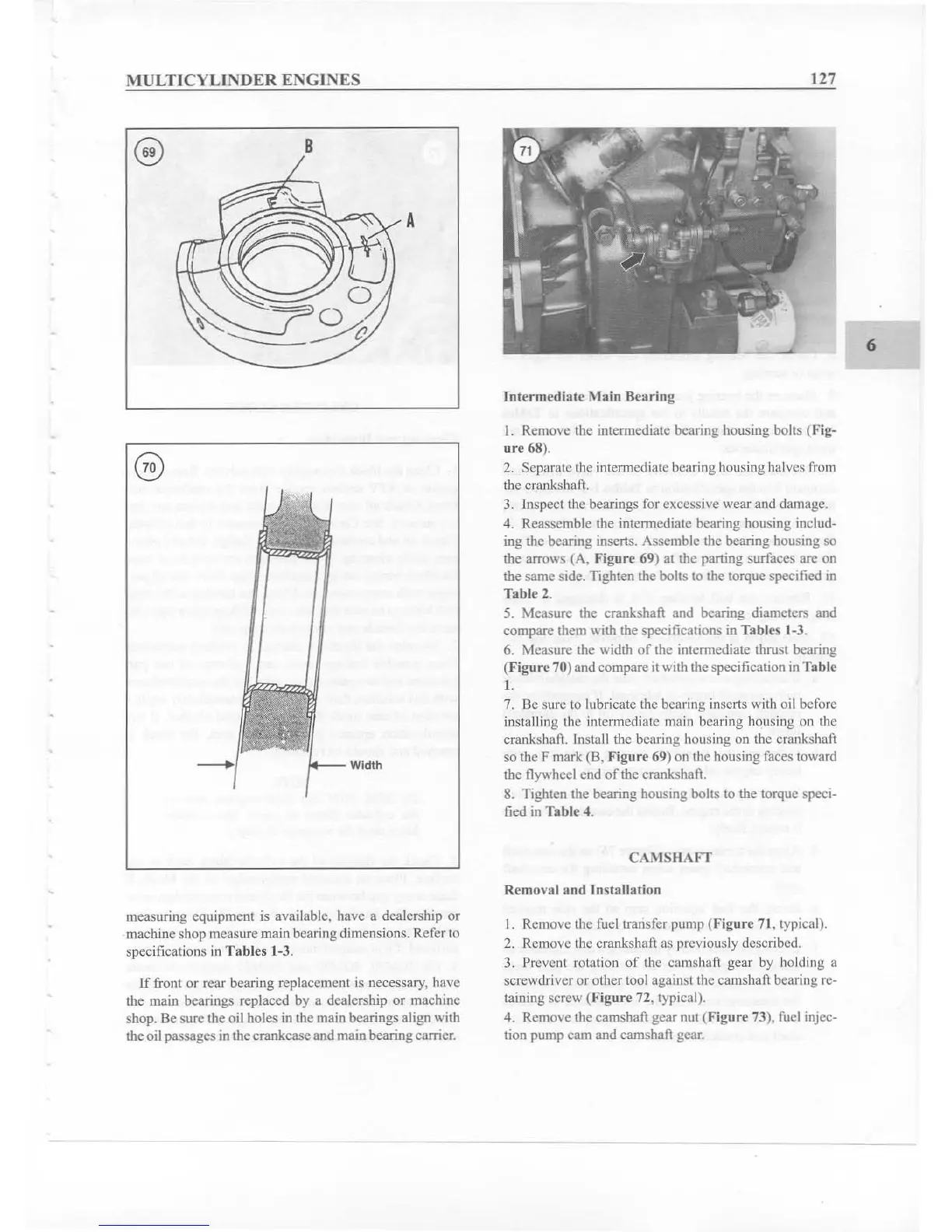

4. Reassemble the intermediate bearing housing includ-

ing the bearing inse

rt

s. Asse mble the bearing housing so

the arrows

(A.

Figure 69) at the parting surfaces are on

the same side.

Tighten the bolts to the torque specified in

Table 2.

5. Measure the crankshaft and bearing diameters and

compare them with the specifications in Tab les 1-3.

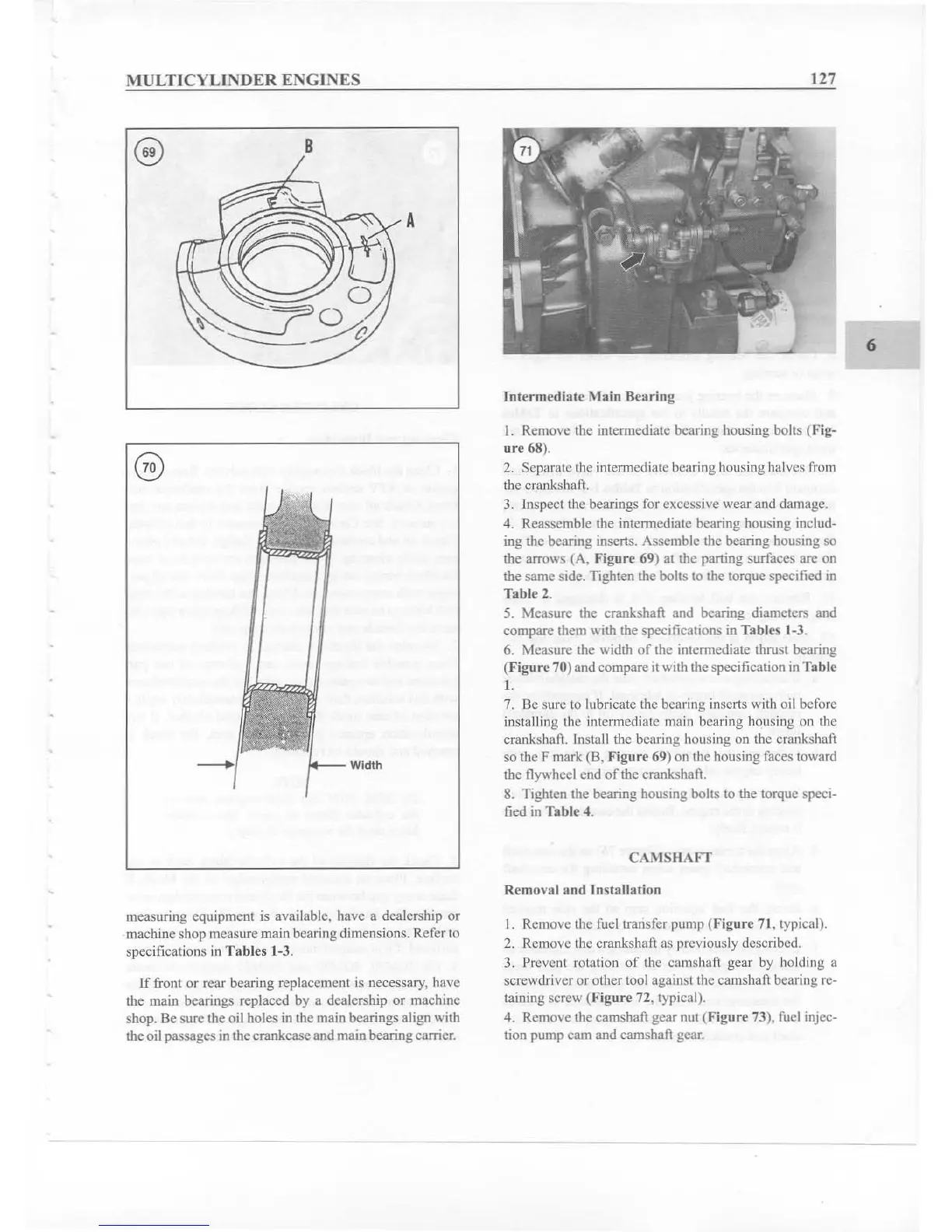

6. Measure the width

of

the intermediate thrust bearing

(Figure 70)and compare itwith the specification inTab le

I.

7. Be sure to lubricate the bearing inserts with oil before

installing the intermediate main bearing housing on the

crankshaft. Install the bearing housing on the crankshaft

so the F mark

(B, Fi

gur

e 69) on the housing faces toward

the flywheel end

of

the crankshaft.

8. Tighten the bearing housing bolts to the torque spcci-

fied in Table

4.

C":\

ISIiAfT

Removal

and

Installation

measuring equipment is available. have a dealership or

machine shop measure main bearing dimensions. R

ef

er to

specifications in Tables 1-3.

If

front or rear bearing rep lacement is necessary. have

the main bearings replaced by a dealership or machine

shop. Be sure the oil holes in the main bearings align with

the oil passages in the

cra

nkcase and mainbearing carrier.

I. Remove thc fuel transfer pump (Figure 71, typical).

2. Remove the crankshaft as previously described.

3. Prevent rotation

of

the camshaft gear by holding a

screwdriver or other tool against the camshaft bearing rc-

taining screw (Figure 72. typical).

4. Remove the camshaft gear nut

(Fi~

ure

73), fuel injec-

tion pump cam and camshaft gear.

Loading...

Loading...