152

seal properl y if reused. Always install new washers when

reconnecting a fitting.

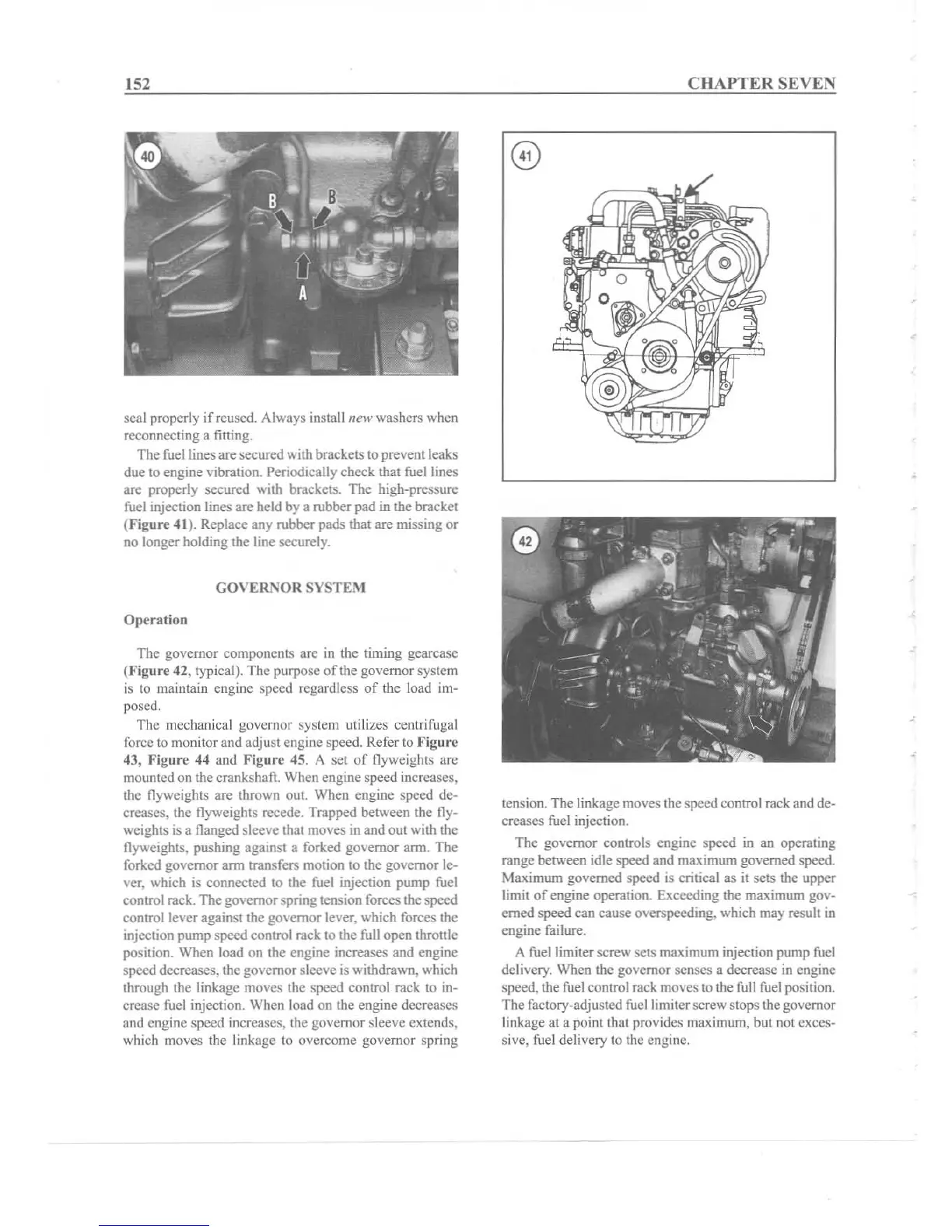

The fuel lines are secured with brackets to prevent leaks

due to

eng

ine vibration. Periodically check that fuel lines

are properly secured with brackets. The high-pressure

fuel injection lines are held by a rubber pad in the bracket

(Figure 41). Replace any rubber pads that are missing or

no longer holding the line securely.

GOVER:\OR

SYSTE:\I

Ope

rat

ion

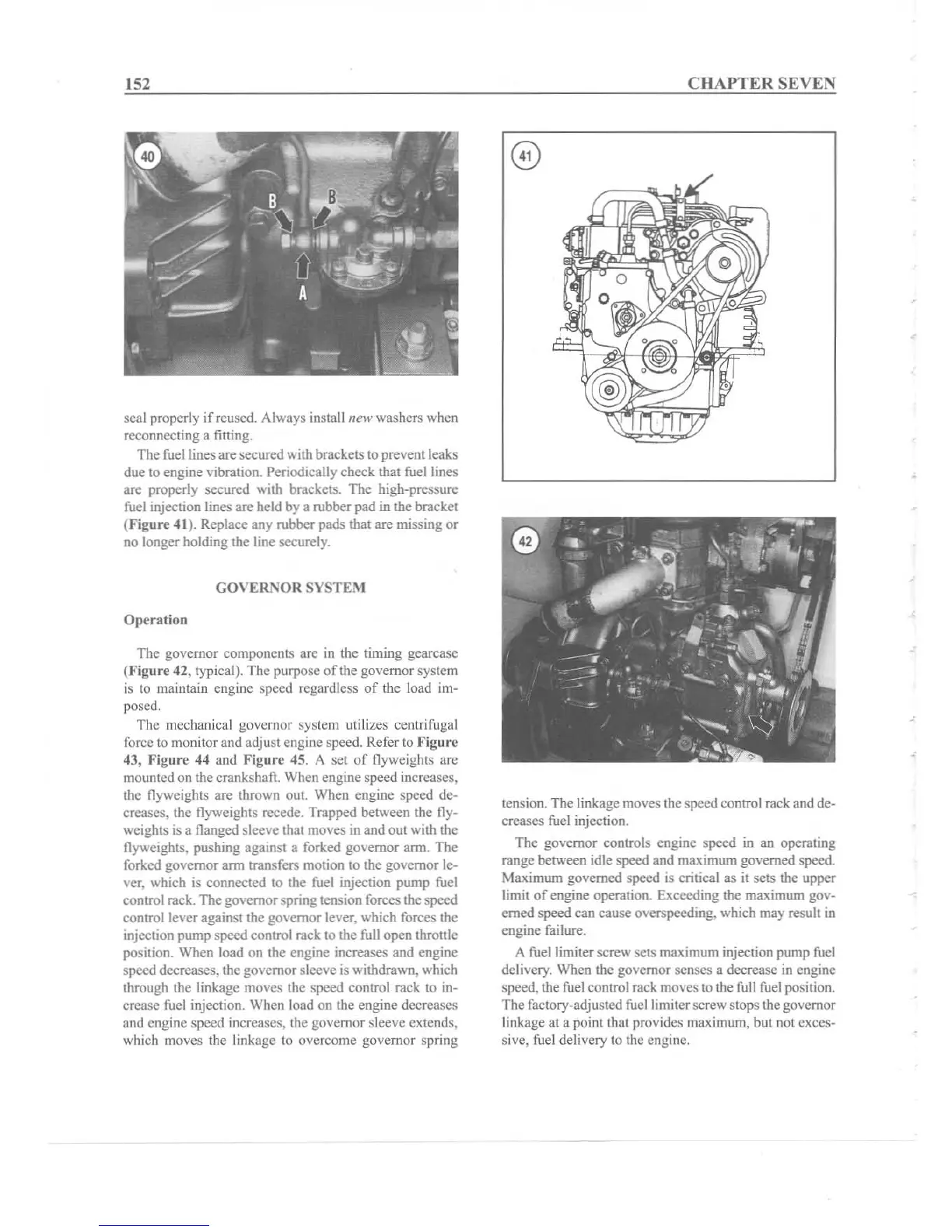

The governor components are in the timing gearcasc

(Flgure 42, typical). The purpose of the governor system

is to maintain engine speed regardless

of

the load im-

posed.

The mechanical governor system utilizes centrifugal

force 10 monitor

and

adjust engine speed. Refer to Fi2u rc

43. Figure 44 and Figure 45. A set

of

flyweights are

mountcd on the crankshaft. When engine speed increases,

the flyweights are thrown out. When engine speed de-

creases, the flyweights

recede. Trapped between the fly-

weights is a flanged sleeve that moves in and out with the

flyweights, pushing against a forked governor arm. The

forked governor arm transfers motion to the governor le-

ver, which is connected to the fuel injection pump fuel

control rack. The governor spring tension forces the

speed

control lever against the governor lever, which forces the

injection pump

speed control rack to the full open throttle

position. When load on the engine increases and engine

speed decreases, the governor sleeve is withdrawn, which

through the linkage moves the speed control rack to in-

crease fuel injection. When load on the engine decreases

and engine

speed increases. the governor sleeve extends,

which moves the linkage to overcome governor spring

CHAPTER

SEVEN

tension. The linkage moves the speed controlrack and de-

creases fuel injection.

The governor controls engine speed in an operating

range between idle speed and maximum governed speed.

Maximum governed speed is critical as it sets the upper

limit

of

engine operation. Exceeding the maximum gov-

erned speed can cause overspceding, which may result in

engine failure.

A fuel limiter screw sets maximum injection pump fuel

delivery. When the governor senses a decrease in engine

speed, the fuel controlrack moves to the full fuelposition.

The factory-adjusted fucllimiter screw stops the governor

linkage at a point that provides maximum, but not exces-

sive, fuel delivery to the engine.

Loading...

Loading...