174

20. Install the cam (5,

Figure

24) and the cam retaining

screw (6).

NOTE

Replace the

pump

impeller anytime it is re-

movedfrom the pump.

If

the original impel-

ler must be reused, make sure to install

it

in

the same rotational direction as originally

installed.

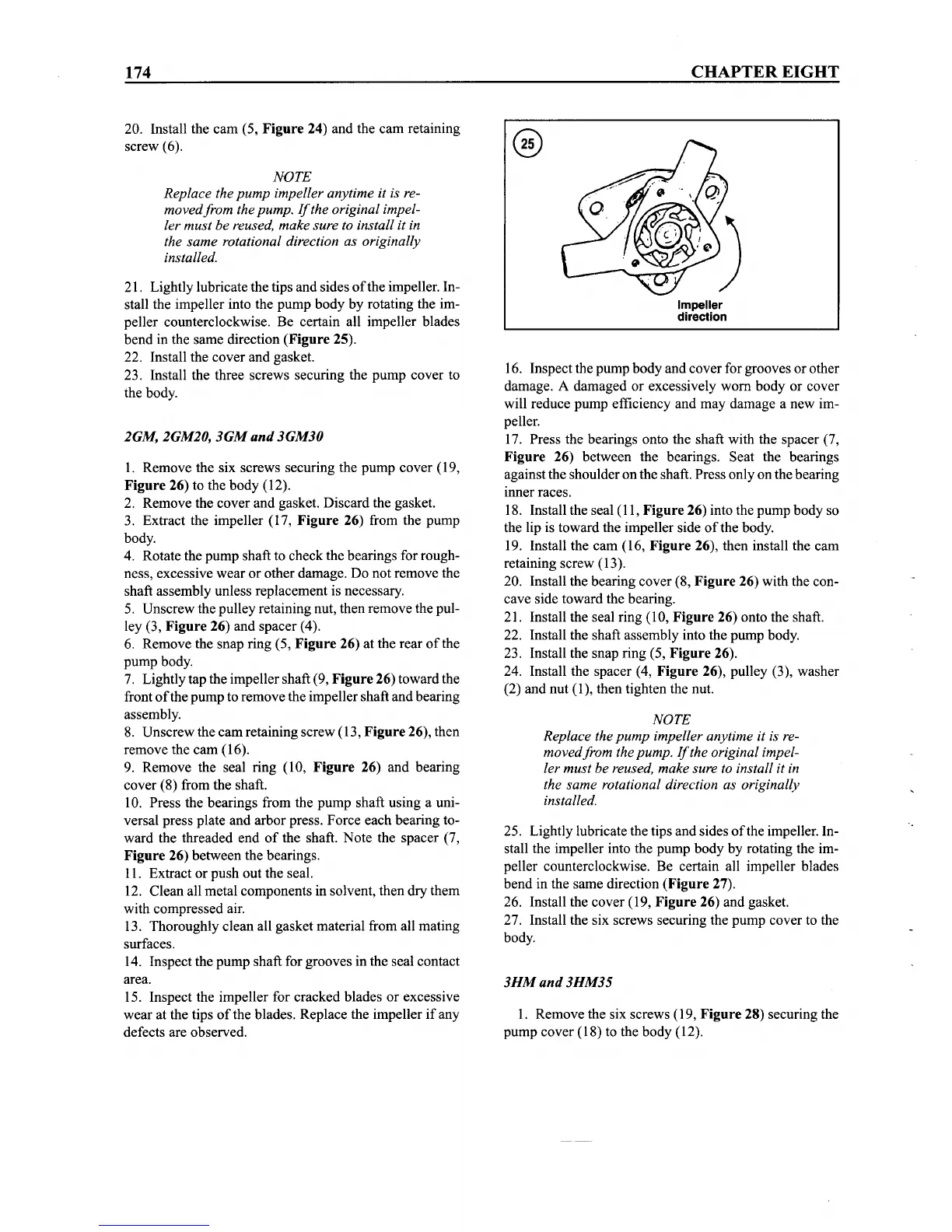

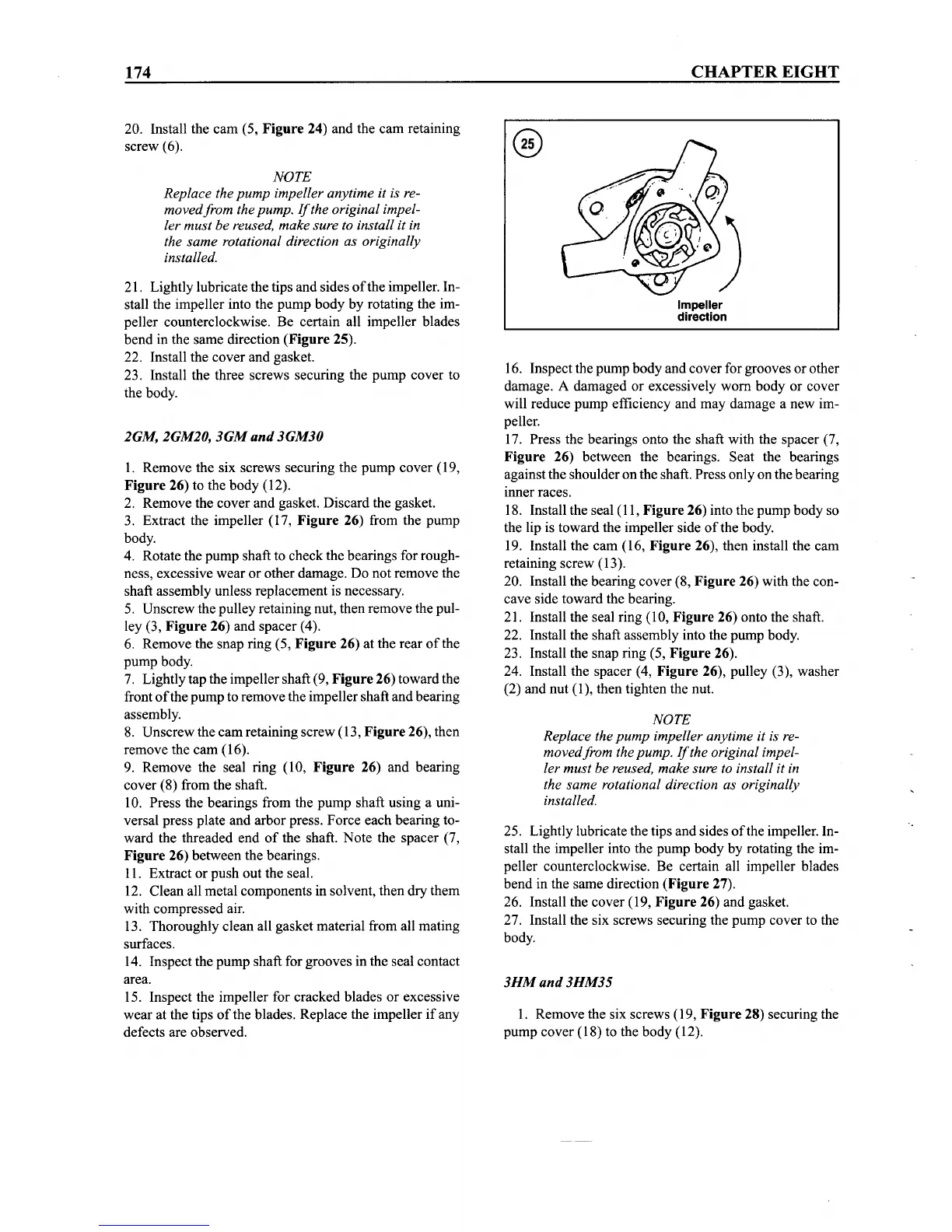

21. Lightly lubricate the tips and sides

of

the impeller. In-

stall the impeller into the pump body by rotating the im-

peller counterclockwise. Be certain all impeller blades

bend in the same direction (Figure 25).

22. Install the cover and gasket.

23. Install the three screws securing the pump cover to

the body.

2GM, 2GM20,

3GM

and

3GM30

1. Remove the six screws securing the pump cover (19,

Figure

26) to the body (12).

2. Remove the cover and gasket. Discard the gasket.

3. Extract the impeller (17,

Figure

26) from the pump

body.

4. Rotate the pump shaft to check the bearings for rough-

ness, excessive wear or other damage. Do not remove the

shaft assembly unless replacement is necessary.

5. Unscrew the pulley retaining nut, then remove the pul-

ley (3,

Figure

26) and spacer (4).

6. Remove the snap ring (5,

Figure

26) at the rear

of

the

pump body.

7. Lightly tap the impellershaft (9,

Figure

26) toward the

front

of

the pump to remove the impeller shaft and bearing

assembly.

8. Unscrew the cam retaining screw (13,

Figure

26), then

remove the cam (16).

9. Remove the seal ring (10,

Figure

26) and bearing

cover (8) from the shaft.

10. Press the bearings from the pump shaft using a uni-

versal press plate and arbor press. Force each bearing to-

ward the threaded end

of

the shaft. Note the spacer (7,

Figure

26) between the bearings.

11. Extract or push out the seal.

12. Clean all metal components in solvent, then dry them

with compressed air.

13. Thoroughly clean all gasket material from all mating

surfaces.

14. Inspect the pump shaft for grooves in the seal contact

area.

15. Inspect the impeller for cracked blades or excessive

wear at the tips

of

the blades. Replace the impeller if any

defects are observed.

CHAPTER

EIGHT

Impeller

direction

16. Inspect the pump body and cover for grooves or other

damage. A damaged or excessively worn body or cover

will reduce pump efficiency and may damage a new im-

peller.

17. Press the bearings onto the shaft with the spacer (7,

Figure

26) between the bearings. Seat the bearings

against the shoulder on the shaft. Press only on the bearing

mnerraces.

18. Install the seal (11,

Figure

26) into the pump body so

the lip is toward the impeller side

of

the body.

19. Install the cam (16,

Figure

26), then install the cam

retaining screw (13).

20. Install the bearing cover (8,

Figure

26) with the con-

cave side toward the bearing.

21. Install the seal ring (10,

Figure

26) onto the shaft.

22. Install the shaft assembly into the pump body.

23. Install the snap ring (5,

Figure

26).

24. Install the spacer (4,

Figure

26), pulley (3), washer

(2) and nut (1), then tighten the nut.

NOTE

Replace the

pump

impeller anytime

it

is re-

movedfrom the pump.

If

the original impel-

ler must be reused, make sure to install it in

the same rotational direction as originally

installed.

25. Lightly lubricate the tips and sides

of

the impeller. In-

stall the impeller into the pump body by rotating the im-

peller counterclockwise. Be certain all impeller blades

bend in the same direction (Figure 27).

26. Install the cover (19,

Figure

26) and gasket.

27. Install the six screws securing the pump cover to the

body.

3HM

and

3HM35

1. Remove the six screws (19,

Figure

28) securing the

pump cover (18) to the body (12).

Loading...

Loading...