212

1. Install the input shaft assembly in the transmission

case.

2. Position the

transmissi~n

case so the open end is up.

3. Install the outer bearing race on the input shaft tapered

bearing.

4. Measure the distance (A, Figure 30) in millimeters

from the mounting flange mating surface on the case to

the top

of

the bearing race. Record the measurement.

5. Measure the distance (B, Figure 31) from the mount-

ing flange mating surface to the bottom

ofthe

bearing race

bore for the input shaft bearing.

6. Subtract the A measurement from the B measurement.

7. From the result obtained in Step 6, subtract 0.0-0.05

mm. This result equals the thickness

of

the shim(s) that

must be installed in the bearing bore in the mounting

flange.

8. Install the shim(s) in the bearing bore in the mounting

flange, then press the bearing outerrace into the mounting

flange on top

of

the shims. Be sure the race is bottomed.

Output

Shaft

In the following procedure to adjust bearing preload,

the neutral position

of

the clutch cone must be established

for proper transmission operation. The desired clutch

cone groove centerline on Model KM2P is 48.3 mm from

the mating surface

of

the transmission case. On Model

KM3P the desired clutch groove centerline is 47.3 mm

from the mating surface

of

the transmission case.

NOTE

To perform the following bearing adjust-

ment procedure, the output shaft must be out

of

the case and the outer bearing races must

be on the bearings and not installed in the

case or mountingflange.

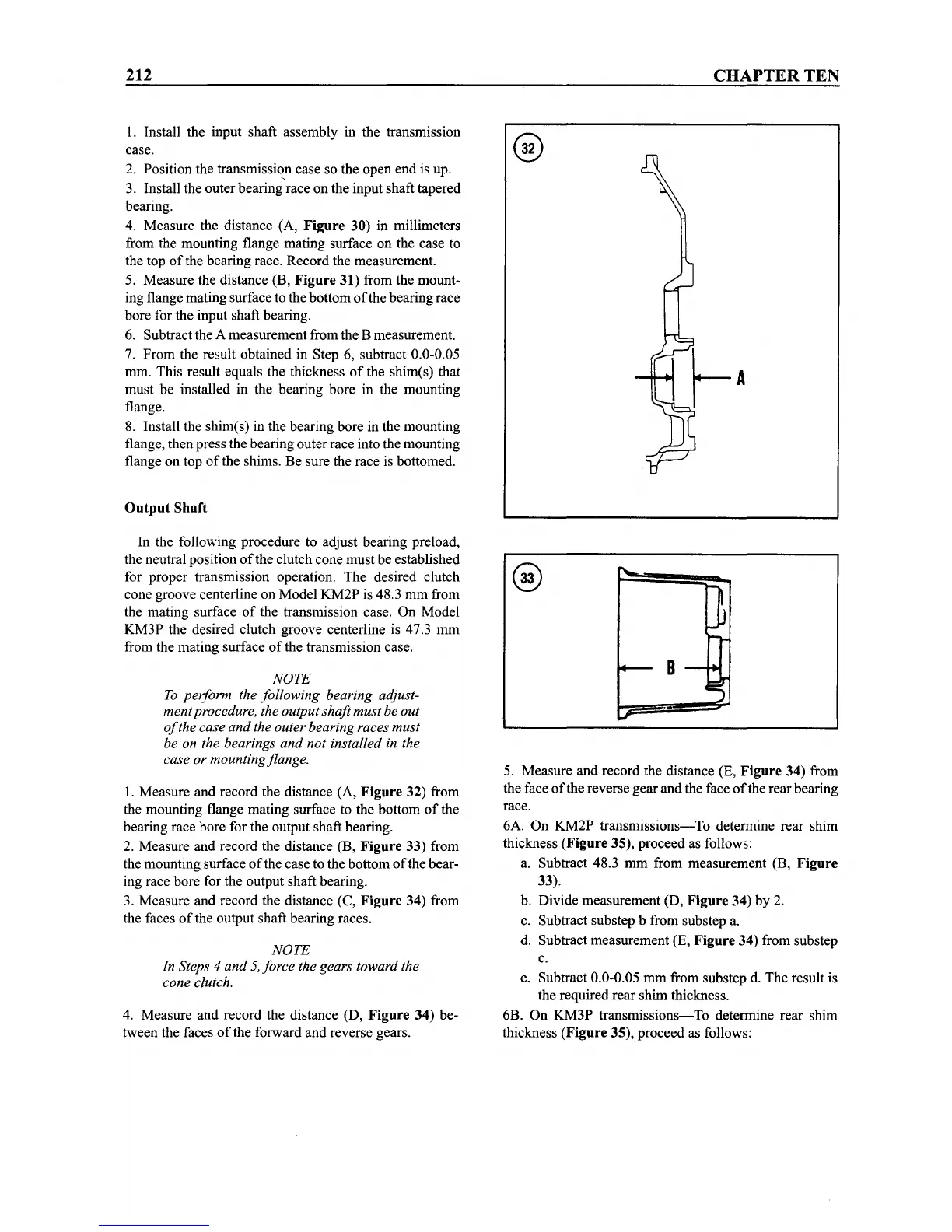

1. Measure and record the distance (A, Figure 32) from

the mounting flange mating surface to the bottom

of

the

bearing race bore for the output shaft bearing.

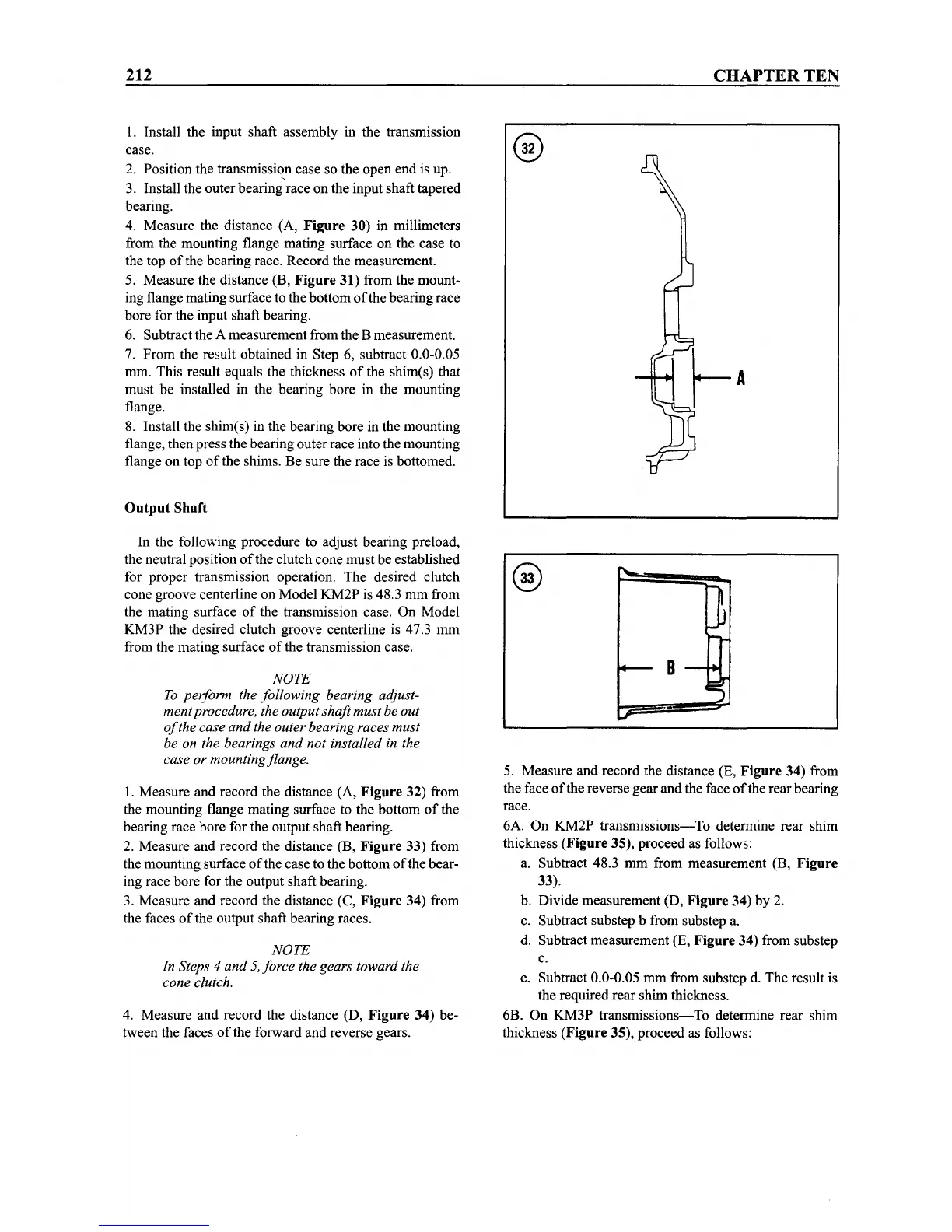

2. Measure and record the distance (B, Figure 33) from

the mounting surface

of

the case to the bottom

ofthe

bear-

ing race bore for the output shaft bearing.

3. Measure and record the distance (C, Figure 34) from

the faces

of

the output shaft bearing races.

NOTE

In Steps

4 and 5,force the gears toward the

cone clutch.

4. Measure and record the distance (D, Figure 34) be-

tween the faces

of

the forward and reverse gears.

CHAPTER

TEN

B

5. Measure and record the distance (E, Figure 34) from

the face

ofthe

reverse gear and the face

ofthe

rear bearing

race.

6A. On KM2P

transmissions-To

determine rear shim

thickness (Figure 35), proceed as follows:

a. Subtract 48.3 mm from measurement (B, Figure

33).

b. Divide measurement (D, Figure 34) by 2.

c. Subtract substep b from substep a.

d. Subtract measurement (E, Figure 34) from substep

c.

e. Subtract 0.0-0.05 mm from substep d. The result is

the required rear shim thickness.

6B. On KM3P

transmissions-To

determine rear shim

thickness (Figure 35), proceed as follows:

Loading...

Loading...