18

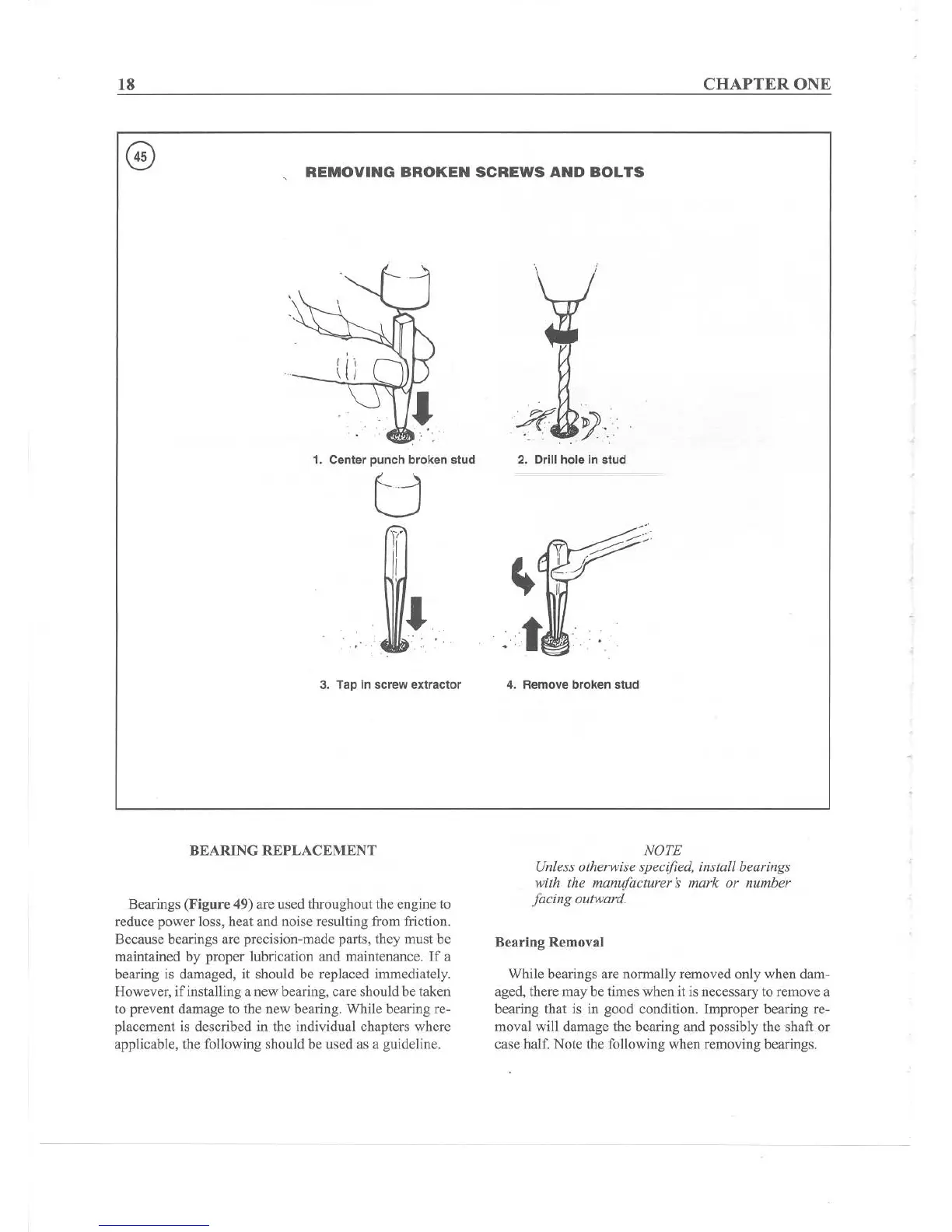

REMOVING

BROKEN

SCREWS

AND

BOLTS

CHAPTER

ONE

1. Center punch broken

stud

3. Tap In screw extractor

BEARING R

EPLAC

EMENT

Bearings (Fi gure 49) are used throughout the engine to

reduce power loss, heat and noise resulting from friction .

Because bearings are precision-made parts, they must be

maintained

by proper lubrication and maintenance.

If

a

bearing is damaged,

it should be replaced immediately.

However,

if

installing a

new

bearing, care should be taken

to prevent damage to the new bearing. While bearing re-

placement is described in the individual chapters where

applicable, the following should be used as a guideline.

!

2. D

rill

hole In

stud

4. Remove

broken

stud

NOTE

Unless otherwise specified, install bearings

with the manufacturer s

mark

or number

facing

outward.

Bearing Removal

While bearings are normally removed only when dam-

aged, there may be times when it is necessary to remove a

bearing that is in good condition. Improper bearing re-

moval will damage the bearing and possibly the shaft or

case half. Note the following when removing bearings.

Loading...

Loading...