40

from a pickup located in the oil pan, then forces oil 10the

necessary engine components.

The

oil pump is driven by

the crankshaft gear.

An oil pressure relief valve regulates oil pressure at

300-400 kPa (43-57 psi). When oil pressure exceeds the

desired pressure, the reliefvalve opens and expels oil into

the liming gearcase. A low oil pressure warning light on

the instrument panel and a warn ing alarm buzzer activate

if oil pressure is below 9.8 kPa

(IA

psi).

Refer

to Chapters Five. Six and Nine for service proce-

dures.

Oil

Pressure

Test

The engine is equipped with an oil pressure warning '

light and alarm thai arc activated

if

low oil pressure oc-

curs. To verify low oil pressure, pc

rf

onn

the following oil

pressu re test.

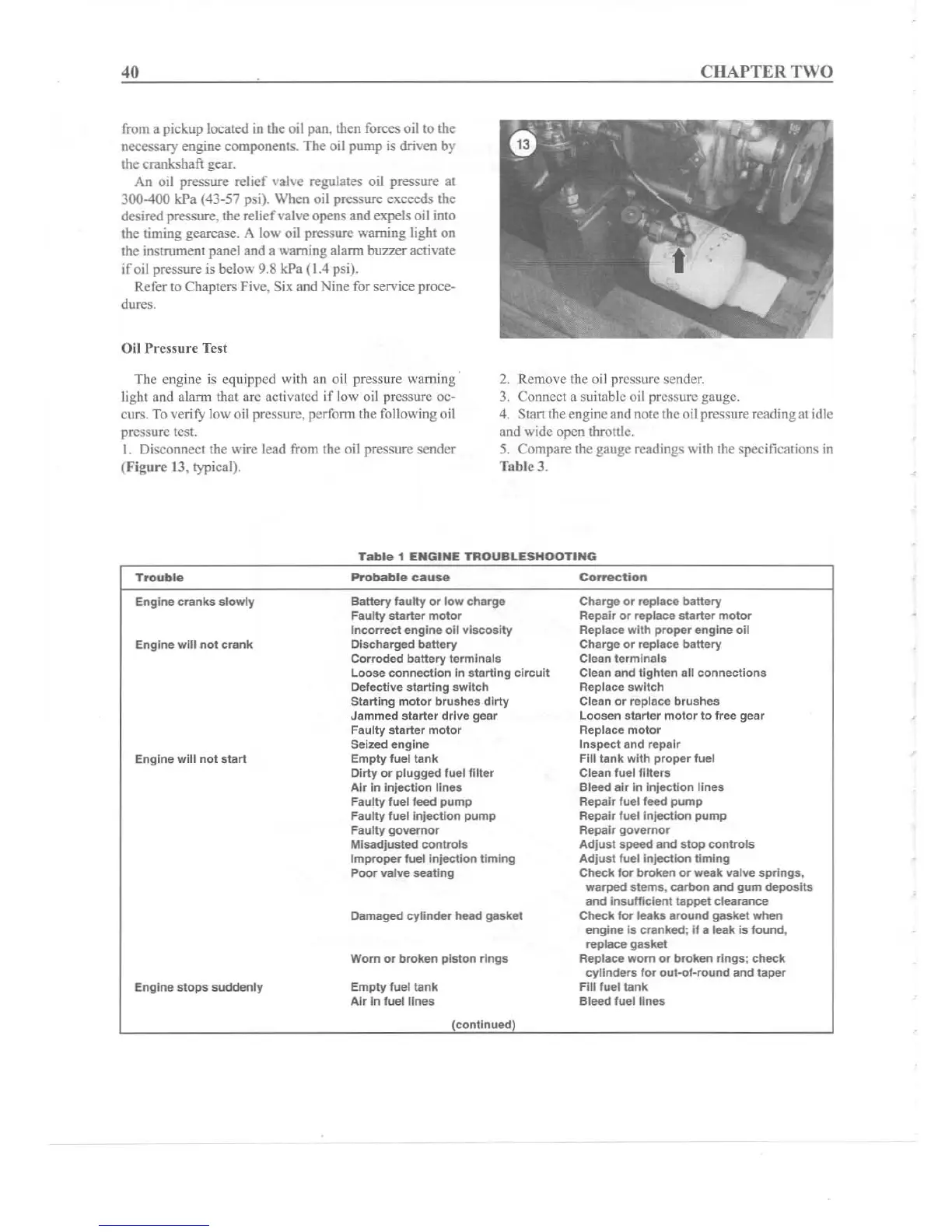

I. Disconnect the wire lead from the oil pressure sender

(

F

i

~ u

r

e

lJ

, typical).

C

HA

P

TE

R

TW

O

2. Remove the oil pressure sender.

3. Connect a suitable oil pressure gauge.

4. Start the engine and note the oil pressure reading at idle

and wide open throttle.

5. Compare the gauge readings with the speeilicat ions in

T

abl

e 3.

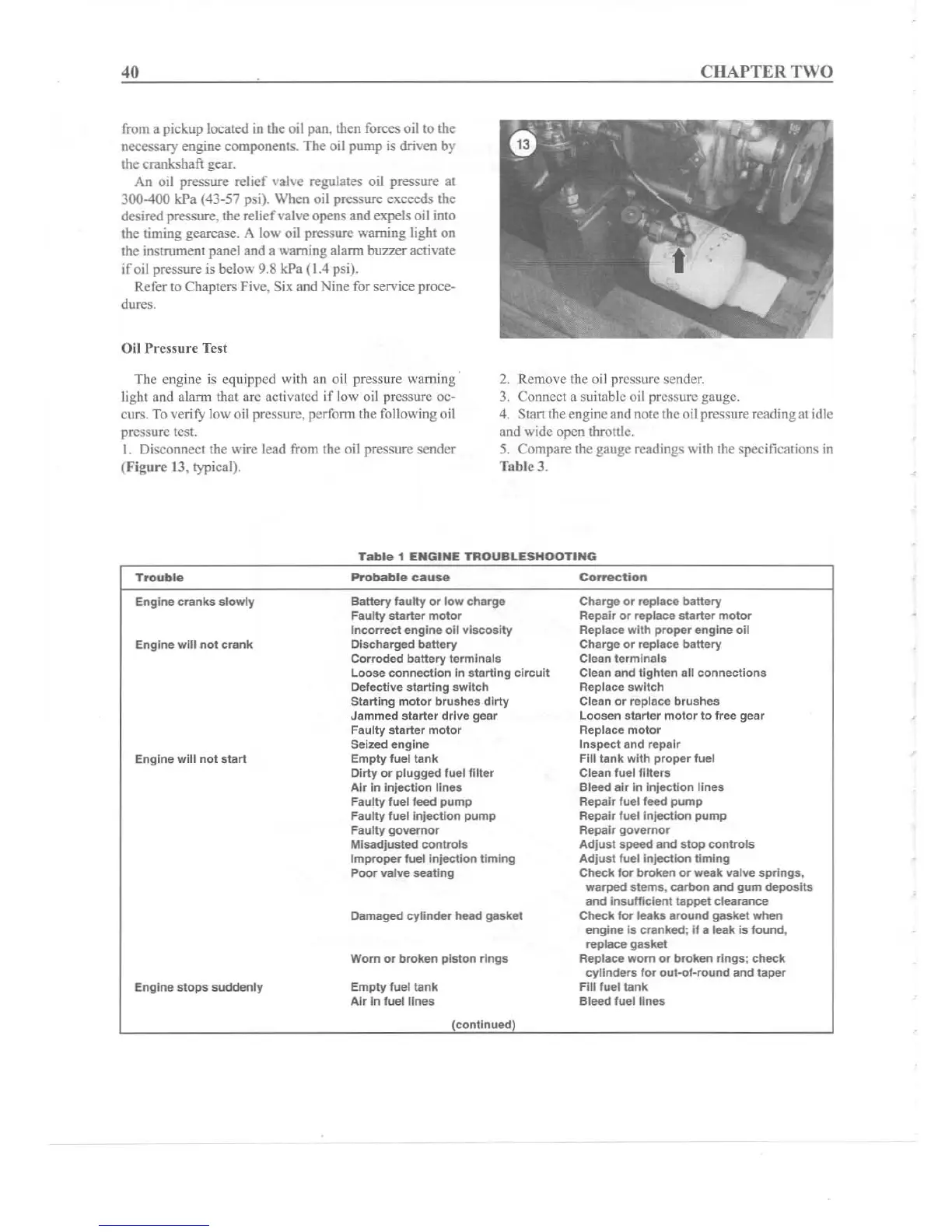

Table

1

ENGINE

TROUBLESHOOTING

Trouble

Engine cr

ank

s slowly

Eng ine

will

not

crank

Engine

will

not

start

Engine sto

ps

suddenly

Probable

cau

..

Battery

fa

ulty

or

~w

charge

Faulty

starter

m

otor

Incorrect

eng

ine

011

viscosity

Discharged

battery

Corroded

battery

termin

als

loose

connection

In starting ci r

cuit

Defective

starting

switch

Starting

motor

brush

es

dirty

Jammed

starter

drive

gear

Faulty

starter

molor

Seized

engine

Empty

fuel

tank

Dirty

or

plugged

tuer f

llte

r

Air

In

inject

ion

lin

es

Faulty

fuel

feed

pump

Faulty

tuel

lnJec:tlon pump

Faulty

go

vernor

Mlsad

ju

sted

controls

Im

proper

luel i

njectIo

n

timing

P

oor

valve

seating

Damaged

cylin

der head gasket

Worn or

broken

piston ring s

Empty

fuel tank

Air

in fuel lines

(

con

t

inued)

Correction

Charge

or re

plac

e

battery

Repair

01"

replace sta

rter

m

otor

Repl ace with p

rope

r

engi

ne

oil

Charge or replace battery

Clean t

ermi

nals

Clean and ti

ght

en

all

connections

Replace switch

Clean or replace bru ehee

loosen

starter

motor

to

Iree

gear

Replace

motor

In

spe

ct and rep

air

Fill tank with pro per luel

Clean fu

ell

ilters

Bleed air In Injection lines

Repair fuel feed pump

Repair luel Injec:tlon

pum

p

Repair govern

or

Adju st speed and st

op

co

ntrols

Adju st fuel inj

ect

ion

liming

C

hec

k

101"

b

roke

n

01"

_ak

valve

springs

,

wa

rped

stems,

carbon

and gum

depos

its

and

insu

ffic

ient tappet clearance

C

hec

k

101"

leaks arou nd gasket when

engine Is cranked; if a

leak

is

fou

nd,

replace gasket

Replace

wor

n

or

brOken rings; chec k

cyli nders for

out-o

f-rou

nd and taper

Fill luel tank

Bleed fuel lines

Loading...

Loading...