OPERATION, LUBRICATION, MAINTENANCE AND TUNE-UP

59

@

VALVE

CLEARANCE

ADJUSTMENT

(ALL

MODELS)

Adjusting screw

CAUTION

Always rotate the crankshaft in the normal

running direction (clockwise at crankshaft

pulley); otherwise the water

pump

impeller

will be damaged.

4. Rotate the crankshaft nut clockwise so the 1T mark on

the flywheel aligns with the reference pointer (B,

Figure

31) on the clutch cover. The piston must be on its com-

pression stroke.

NOTE

Some transmissions do not have an opening

in the clutch cover. Remove the starter to

view the timing marks on the flywheel (Fig-

ure 33).

IDLE

SPEED

ADJUSTMENT

(1GM

AND

1GM10

MODELS)

rough engine operation and possible engine damage, such

as burnt valves. Excessive valve clearance will reduce en-

gine performance. The recommended interval for valve

adjustment is after every 300 hours

of

operation. How-

ever, it is a good practice to check the valve clearances

during each tune-up.

The engine must be cold when adjusting valve clear-

ance. On multicylinderengines, the cylinder nearest the

flywheel is the number one cylinder.

1. Remove the rocker arm cover as described in Chapter

Five or Six.

2. Observe the flywheel (A,

Figure

31) through the open-

ing in the clutch cover. A cylinder is at top dead center

if

the mark on the flywheel is aligned with the reference

pointer (B) on the clutch cover.

3. Rotate the crankshaft with a wrench on the crankshaft

pulley retaining nut

(Figure

32).

..

,""\-"~'

,.....-

..

-<:

j-

..-

l ..

'--"~

Idle

speed

screw

NOTE

When thepiston is on its compression stroke

and

at top dead center, both valves will be

closed. This can be determined by the posi-

tion

of

the intake

and

exhaust rocker arms.

Both should have free play, which indicates

that the valves are closed.

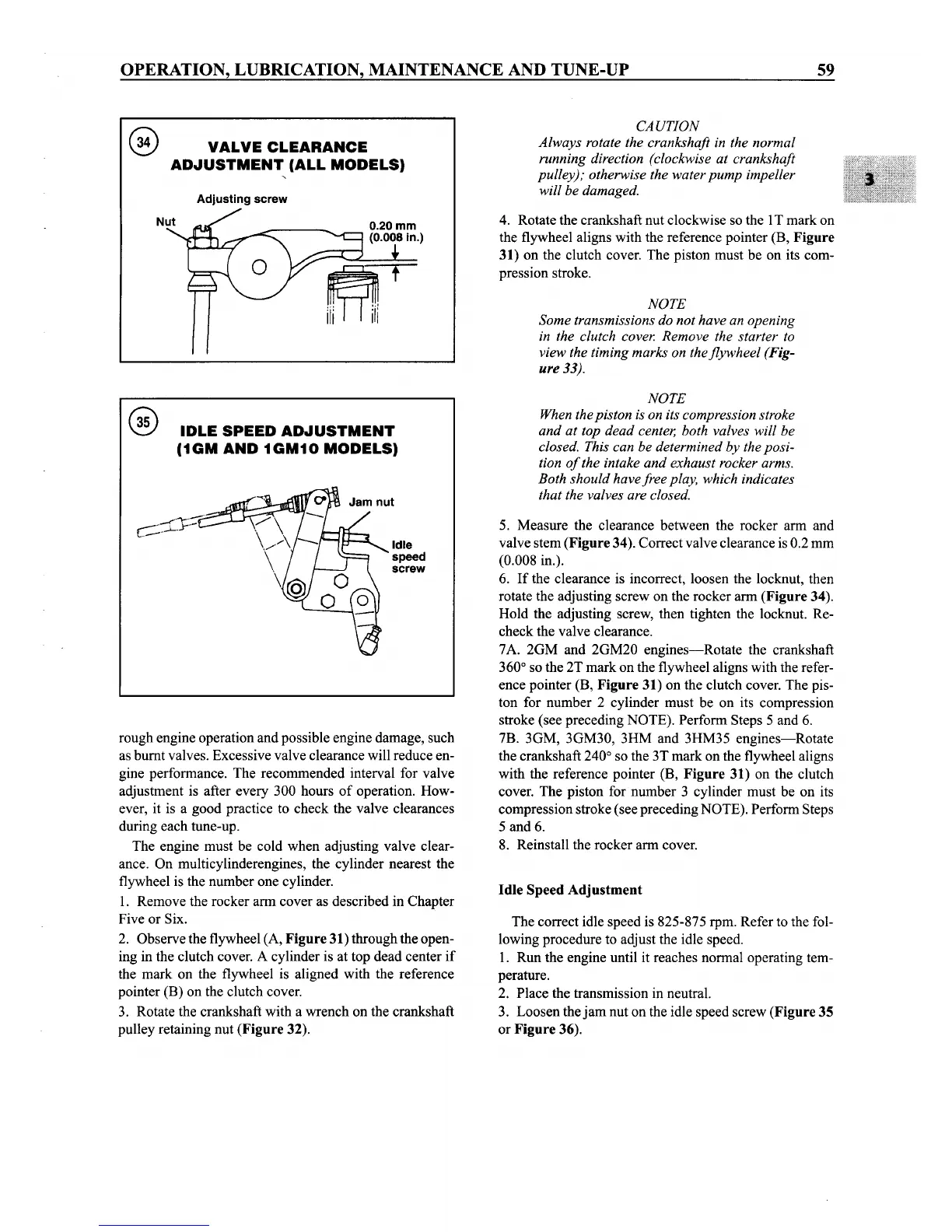

5. Measure the clearance between the rocker arm and

valve stem

(Figure

34). Correct valve clearance is 0.2 mm

(0.008 in.).

6.

If

the clearance is incorrect, loosen the locknut, then

rotate the adjusting screw on the rocker arm

(Figure

34).

Hold the adjusting screw, then tighten the locknut. Re-

check the valve clearance.

7A. 2GM and 2GM20

engines-Rotate

the crankshaft

360

0

so the 2T mark on the flywheel aligns with the refer-

ence pointer (B,

Figure

31) on the clutch cover. The pis-

ton for number 2 cylinder must be on its compression

stroke (see preceding NOTE). Perform Steps 5 and 6.

7B. 3GM, 3GM30, 3HM and 3HM35

engines-Rotate

the crankshaft 240

0

so the 3T mark on the flywheel aligns

with the reference pointer (B,

Figure

31) on the clutch

cover. The piston for number 3 cylinder must be on its

compression stroke (see preceding NOTE). Perform Steps

5 and 6.

8. Reinstall the rocker arm cover.

Idle

Speed

Adjustment

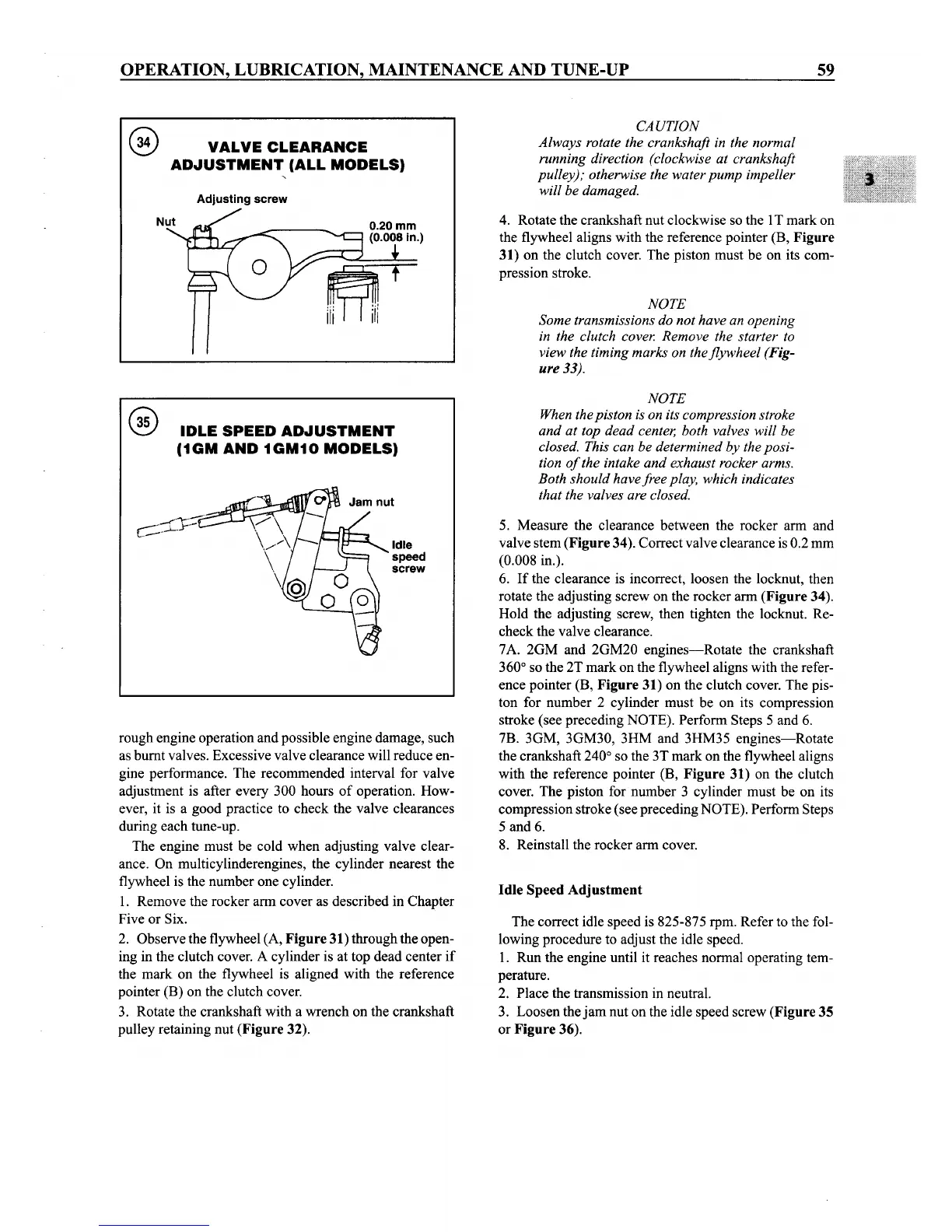

The correct idle speed is 825-875 rpm. Refer to the fol-

lowing procedure to adjust the idle speed.

1. Run the engine until it reaches normal operating tem-

perature.

2. Place the transmission in neutral.

3. Loosen the

jam

nut on the idle speed screw

(Figure

35

or

Figure

36).

Loading...

Loading...