SINGLE-CYLINDER

ENGINES

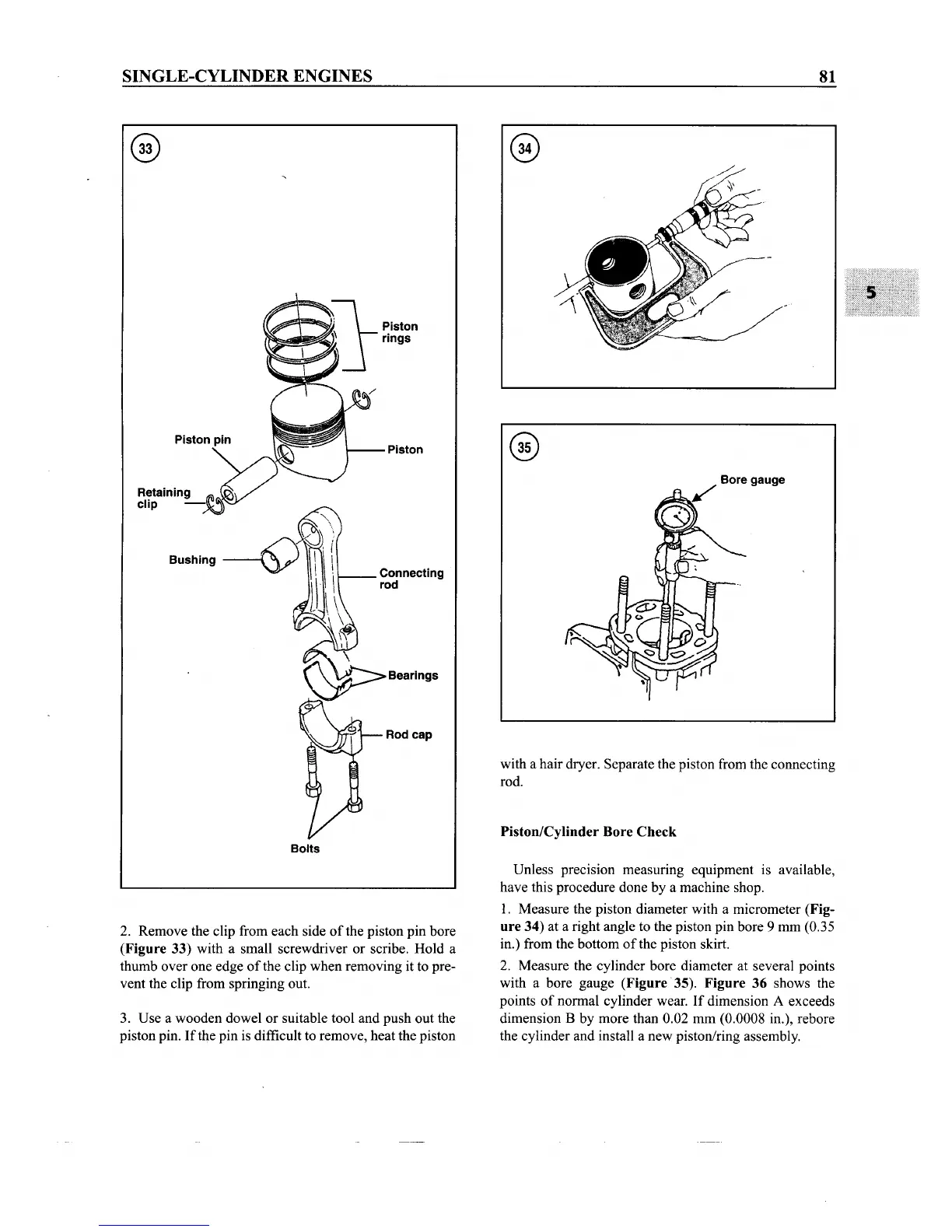

Piston

Connecting

rod

Bearings

Rod cap

Bolts

2. Remove the clip from each side

of

the piston pin bore

(Figure 33) with a small screwdriver or scribe. Hold a

thumb over one edge

of

the clip when removing it to pre-

vent the clip from springing out.

3. Use a wooden dowel or suitable tool and push out the

piston pin.

If

the pin is difficult to remove, heat the piston

81

with a hair dryer. Separate the piston from the connecting

rod.

Piston/Cylinder Bore

Check

Unless precision measuring equipment is available,

have this procedure done by a machine shop.

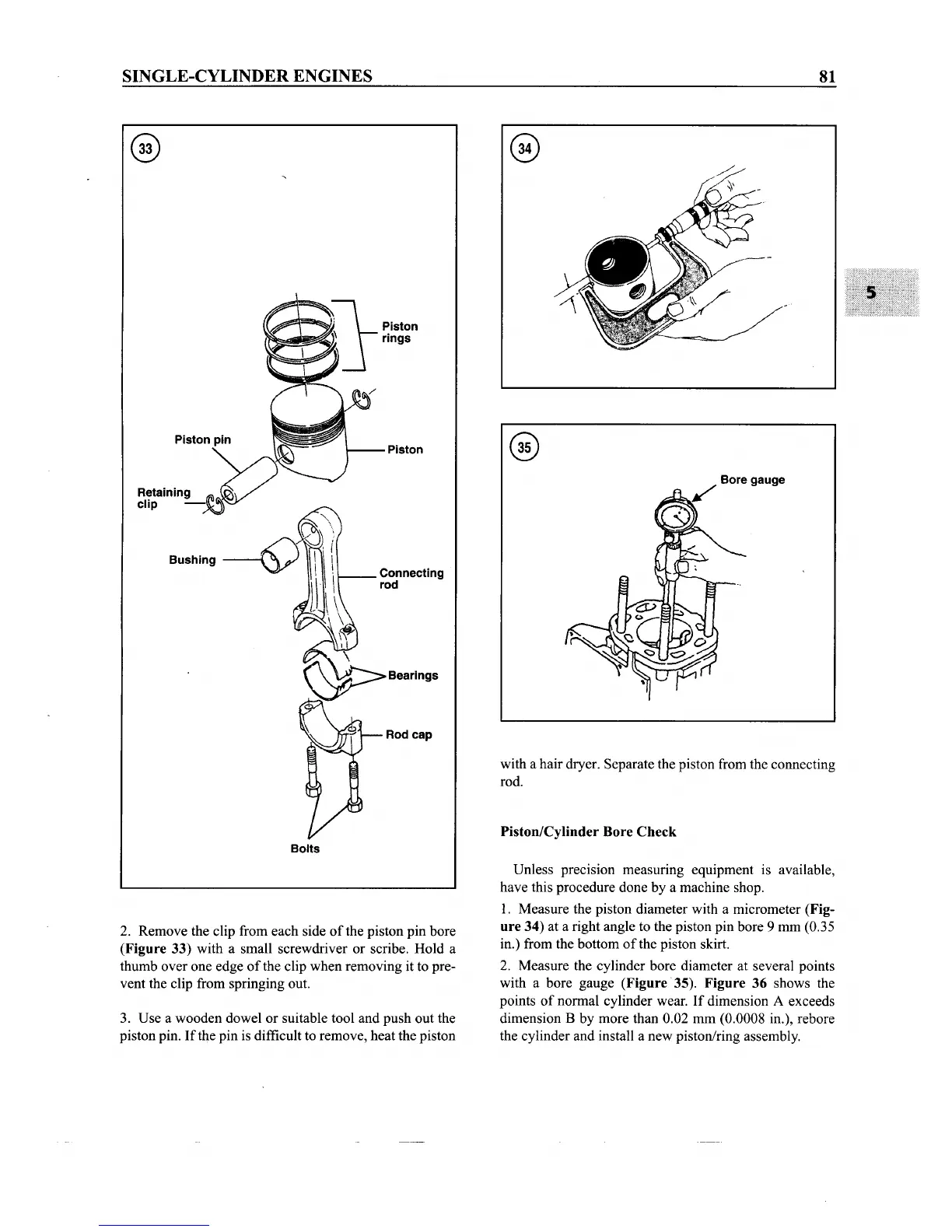

1. Measure the piston diameter with a micrometer (Fig-

ure

34) at a right angle to the piston pin bore 9 mm (0.35

in.) from the bottom

of

the piston skirt.

2. Measure the cylinder bore diameter at several points

with a bore gauge (Figure 35). Figure 36 shows the

points

of

normal cylinder wear.

If

dimension A exceeds

dimension B by more than 0.02 mm (0.0008 in.), rebore

the cylinder and install a new piston/ring assembly.

Loading...

Loading...