88

CHAPTER

FIVE

/

/

/

Outer rotor

Inner

rotor

/ J

~

;;~:J-k';:-

-

Feeler gauge

9. Installation is the reverse

of

removal. Tighten the oil

pump retaining screws to the tightening torque specified

in Tabl e 2. Make sure the governor flyweight assembly is

positioned on the locating pins

(Figure

60). Tighten the

crankshaft nut to the torque specified in Table 2.

Disassembly, inspection

and

reassembly

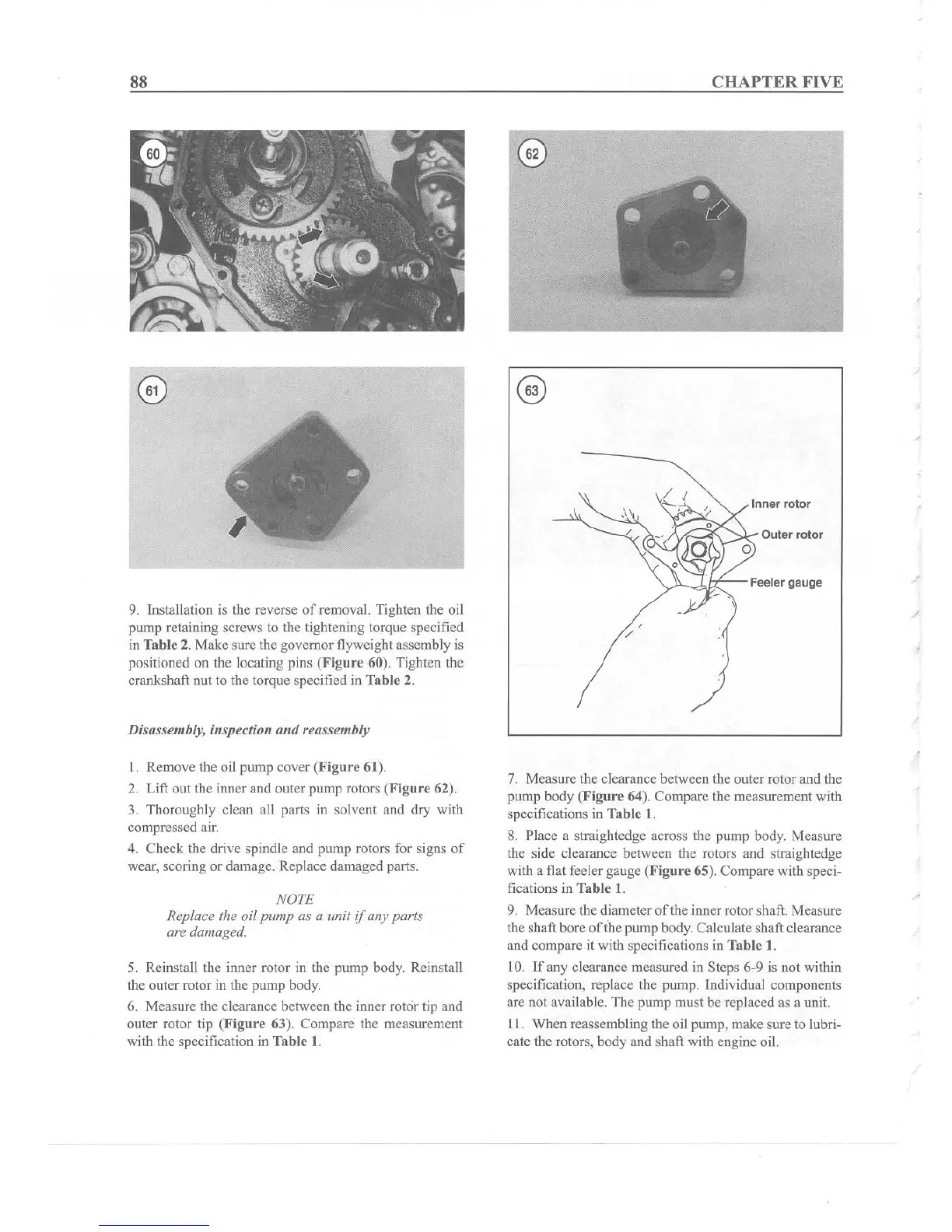

1. Remove the oil pump cover

(Fig

ure

61).

2. Lift out the inner and outer pump rotors (F

igure

62).

3. Thoroughly clean all parts in solvent and dry with

compressed air.

4. Check the drive spindle and pump

rotors for signs

of

wear, scoring or damage. Replace damaged parts.

NOTE

Replace the oil

pump

as a unit

if

any parts

are damaged.

5. Reinstall the inner rotor in the pump body. Reinstall

the outer rotor in the pump body.

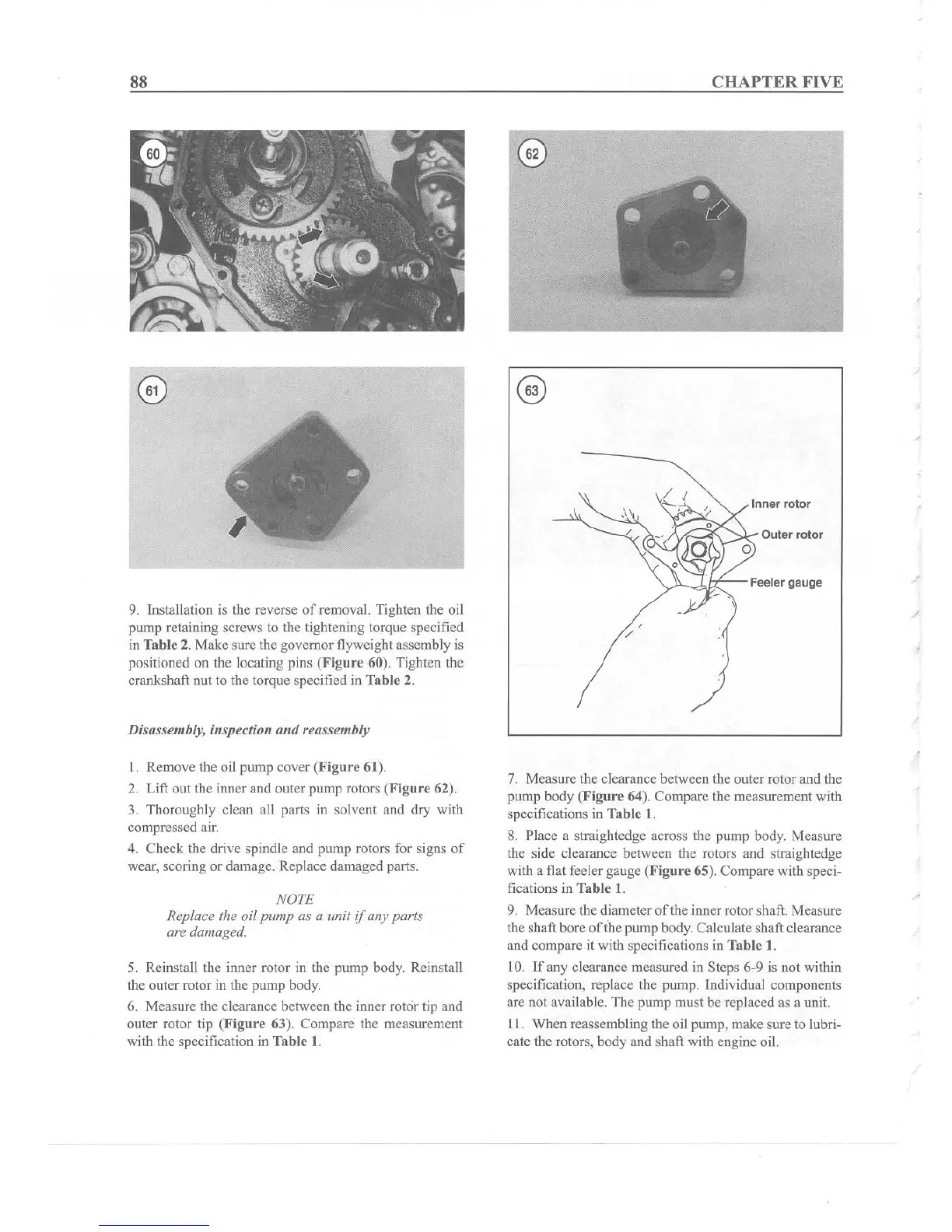

6. Measure the clearance between the inner

rotor tip and

outer rotor tip

(Figure

63). Compare the measurement

with the specification in

Tab

le 1.

7. Measure the clearance between the outer rotor and the

pump body

(Figur

e 64). Compare the measurement with

specifications in

Table I.

8. Place a straightedge across the pump body. Measure

the side clearance between the rotors and straightedge

with a flat feeler gauge (Fig

ure

65). Compare with speci-

fications in Table

I.

9. Measure the diameter

of

the inner rotor shaft. Measure

the shaft bore

of

the pump body. Calculate shaft clearance

and compare it with specifications in

Tab

le 1.

10. If any clearance measured in Steps 6-9 is not within

specification, replace the pump. Individual components

are not available. The pump must be replaced as a unit.

11

. When reassembling the oil pump, make sure to lubri-

cate the rotors, body and shaft with engine oil.

Loading...

Loading...