56

flush it down a drain or

pour

it on the

ground. Put it in suitable containers and

dispose

of

it according to local regulations.

CAUTION

Be careful not to spill antifreeze on painted

surfaces, as it may damage the surface.

Wash any spilled antifreeze immediately

with soapy water, then rinse the area thor-

oughly with clean water.

Flushing

and

refillingfreshwater coolant system

Use the following procedure to flush and refill the

freshwater coolant system. Refer to the preceding section

to flush the seawater portion

of

a freshwater coolant sys-

tem.

Replace the coolant in the freshwater coolant system af-

ter every 500 hours

of

operation or annually, whichever

occurs first.

CAUTION

Perform the following procedure when the

engine is cold.

1. Remove the pressure fill cap (Figure 24).

NOTE

Position the drain hoses in suitable contain-

ers to catch coolant when draining the cool-

ant from the exhaust manifold and engine.

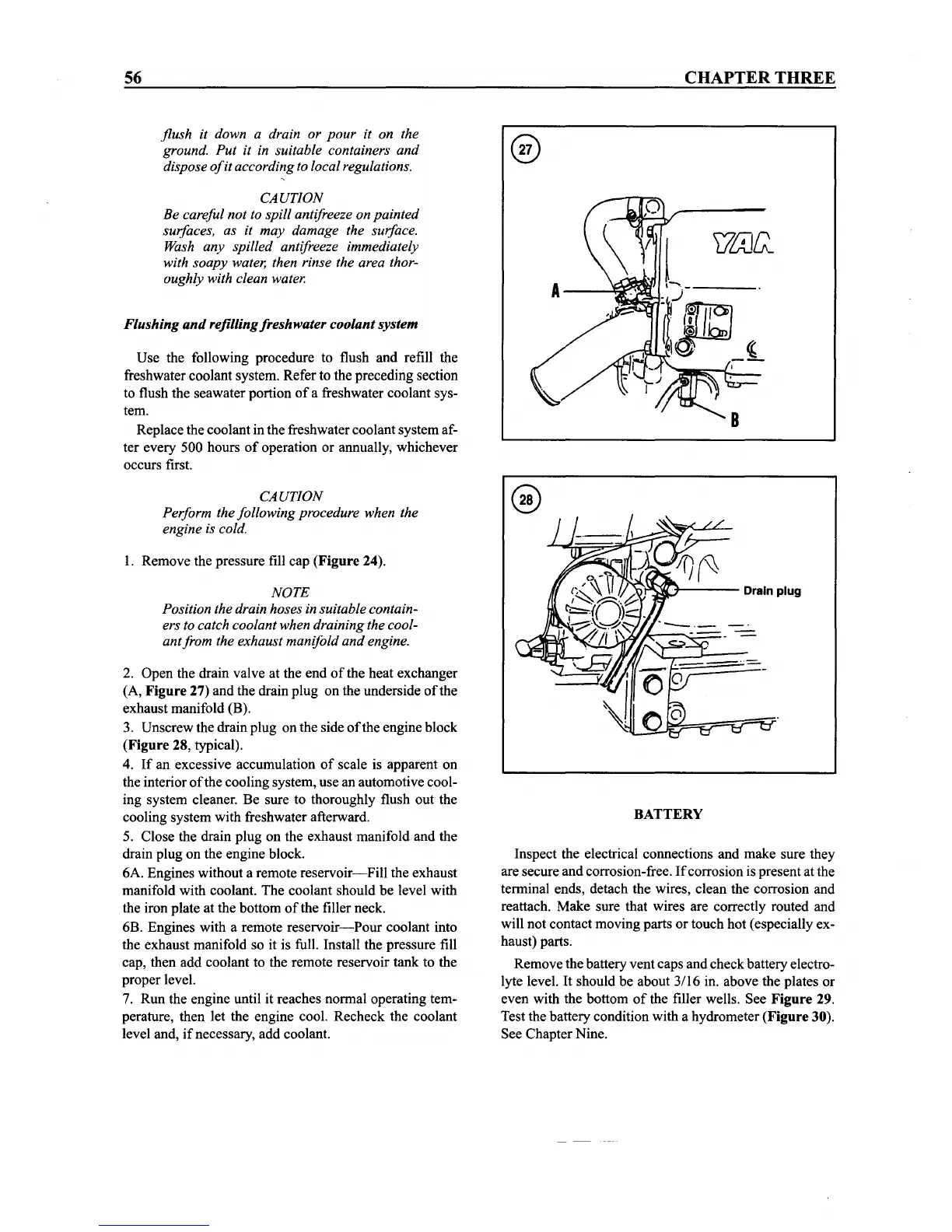

2. Open the drain valve at the end

of

the heat exchanger

(A, Figure 27) and the drain plug on the underside

of

the

exhaust manifold (B).

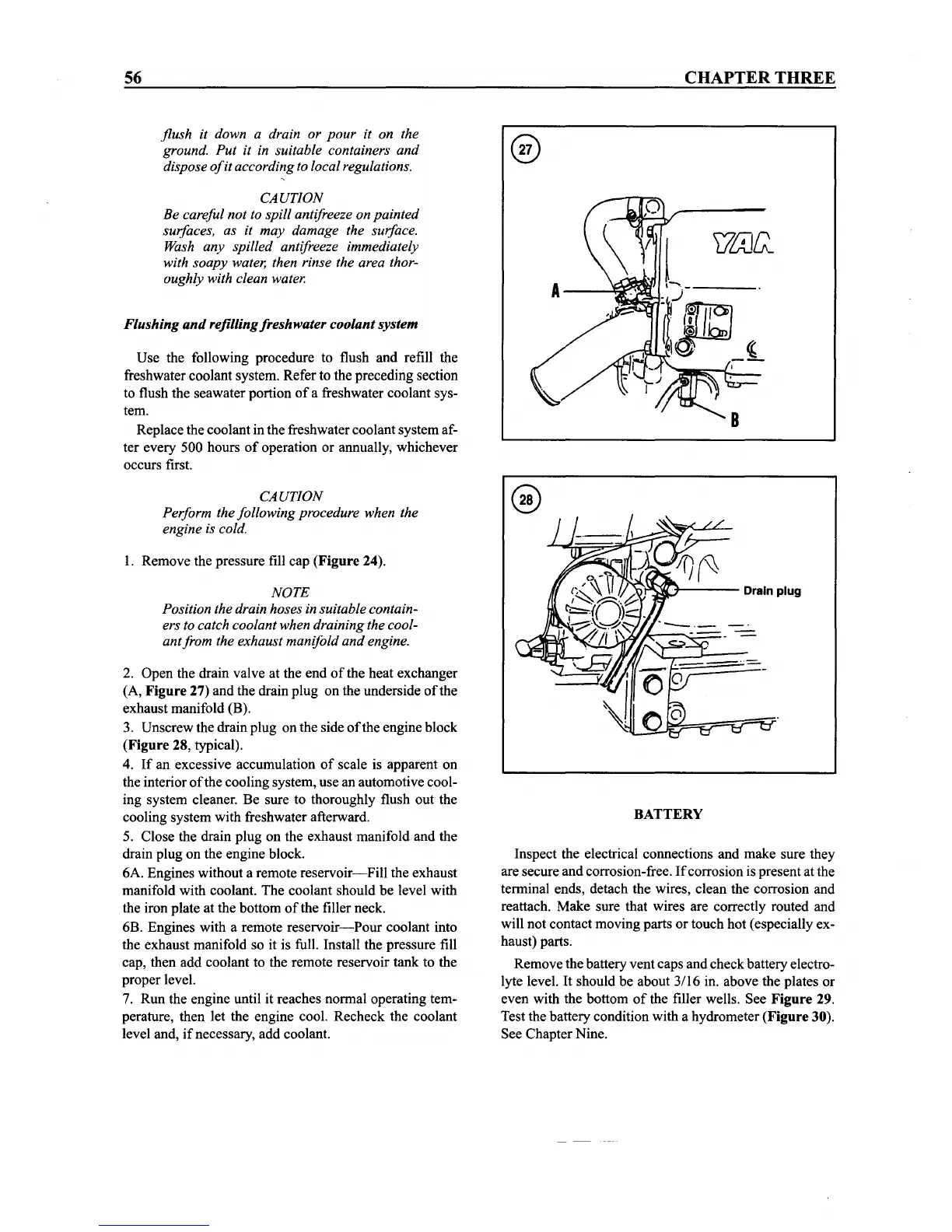

3. Unscrew the drain plug on the side

of

the engine block

(Figure 28, typical).

4.

If

an excessive accumulation

of

scale is apparent on

the interior

ofthe

cooling system, use an automotive cool-

ing system cleaner. Be sure to thoroughly flush out the

cooling system with freshwater afterward.

5. Close the drain plug on the exhaust manifold and the

drain plug on the engine block.

6A. Engines without a remote

reservoir-Fill

the exhaust

manifold with coolant. The coolant should be level with

the iron plate at the bottom

of

the filler neck.

68.

Engines with a remote

reservoir-Pour

coolant into

the exhaust manifold so it is full. Install the pressure fill

cap, then add coolant to the remote reservoir tank to the

proper level.

7. Run the engine until it reaches normal operating tem-

perature, then let the engine cool. Recheck the coolant

level and,

if

necessary, add coolant.

CHAPTER

THREE

~)y;;:1r~"":""_-

Drain plug

BATTERY

Inspect the electrical connections and make sure they

are secure and corrosion-free.

If

corrosion is present at the

terminal ends, detach the wires, clean the corrosion and

reattach. Make sure that wires are correctly routed and

will not contact moving parts or touch hot (especially ex-

haust) parts.

Remove the battery vent caps and check battery electro-

lyte level.

It

should be about 3/16 in. above the plates or

even with the bottom

of

the filler wells. See Figure 29.

Test the battery condition with a hydrometer (Figure30).

See Chapter Nine.

Loading...

Loading...