Chapter 2 Basic Engine

6. Connecting Rod

M4LHA Seri.

6-3

Piston

pin

bushing

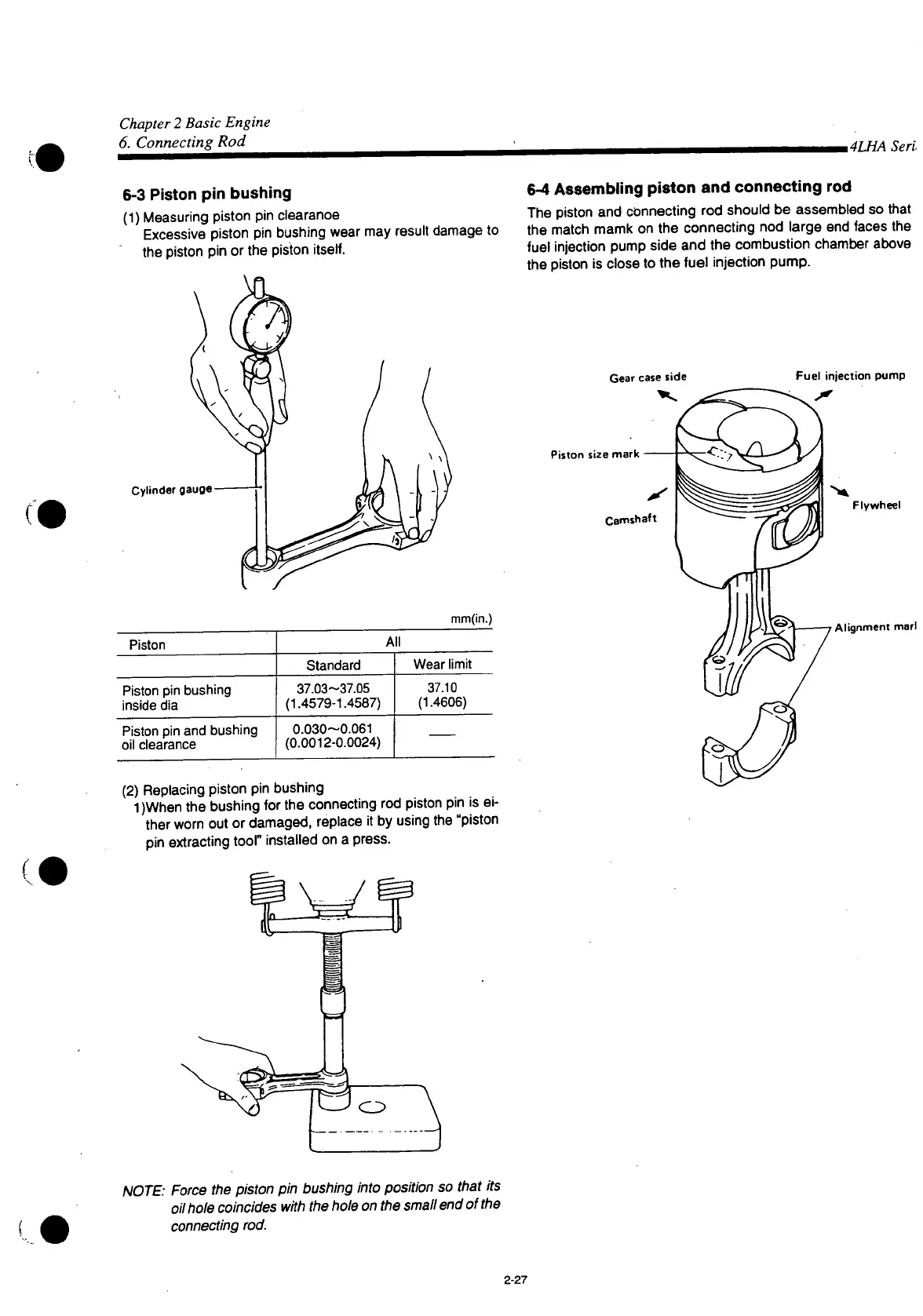

(1)

Measuring

piston pin clearanoe

Excessive

piston pin bushing wear may result damage to

the piston pin or the piston

itself.

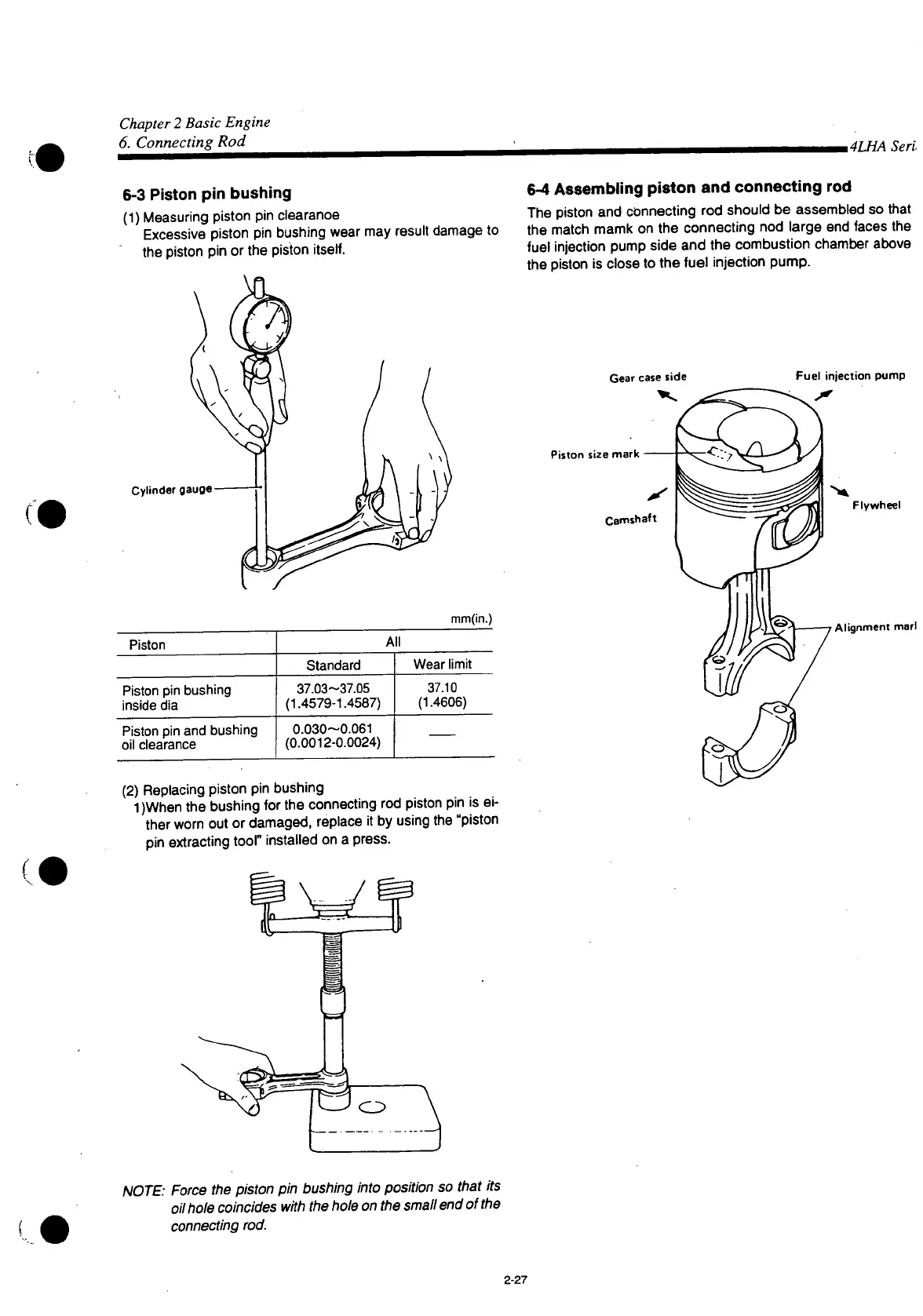

6-4 Assembling

piston

and

connecting

rod

The

piston and connecting rod should be

assembled

so

that

the match mamk on the connecting nod large end

faces

the

fuel injection pump

side

and the combustion chamber above

the piston is

close

to the fuel injection pump.

Cylinder

gauge

Gear

case

side

Fuel

injection pump

Piston

size

mark

mm(in.)

Piston

All

Standard

Wear

limit

Piston

pin bushing

inside

dia

37.03-37.05

(1.4579-1.4587)

37.10

(1.4606)

Piston

pin and bushing

oil clearance

0.030-0.061

(0.0012-0.0024)

(2)

Replacing

piston pin bushing

1)When the bushing for the connecting rod piston pin is ei-

ther worn out or

damaged,

replace it by using the "piston

pin extracting tool" installed on a

press.

Flywheel

Alignment marl

NOTE: Force the piston

pin

bushing into position

so that its

oil

hole coincides with the hole on the small end

of the

connecting rod.

2-27

Loading...

Loading...