Chapter 3 Fuel Injection Equipment

8. Troubleshooting

4LHA Series

8.

Troubleshooting

8-1

Troubleshooting

of

Fuel

Injection

Pump

Complete

repair

means

not

only

replacing

defective

parts,

but

finding

and

eliminating

the

cause

of the

trou-

ble as

well.

The

cause

of the

trouble

may not

necessarily

be in the

pump

itself,

but may be in the

engine

or the

fuel

system.

If the

pump

is

removed

prematurely,

the

true

cause

of the

trouble

may

never

be

known.

Before

removing

the

pump

from

the

engine,

at

least

go

through

the

basic

check

points

given

here.

8-2

Major

Faults

and

Troubleshooting

Basic

check

points

•

Check

for

breaks

or oil

leaks

throughout

the

fuel

system,

from

the

fuel

tank

to the

nozzle.

•

Check

the

injection

timings

for all

cylinders.

Are

they

correctly

adjusted?

Are

they

too

fast

or too

slow?

•

Check

the

nozzle

spray.

•

Check

the

fuel

delivery.

Is it in

good

condition?

Loosen

the

fuel

pipe

connection

at the

injection

pump

inlet,

and

test

operate

the

fuel

feed

pump.

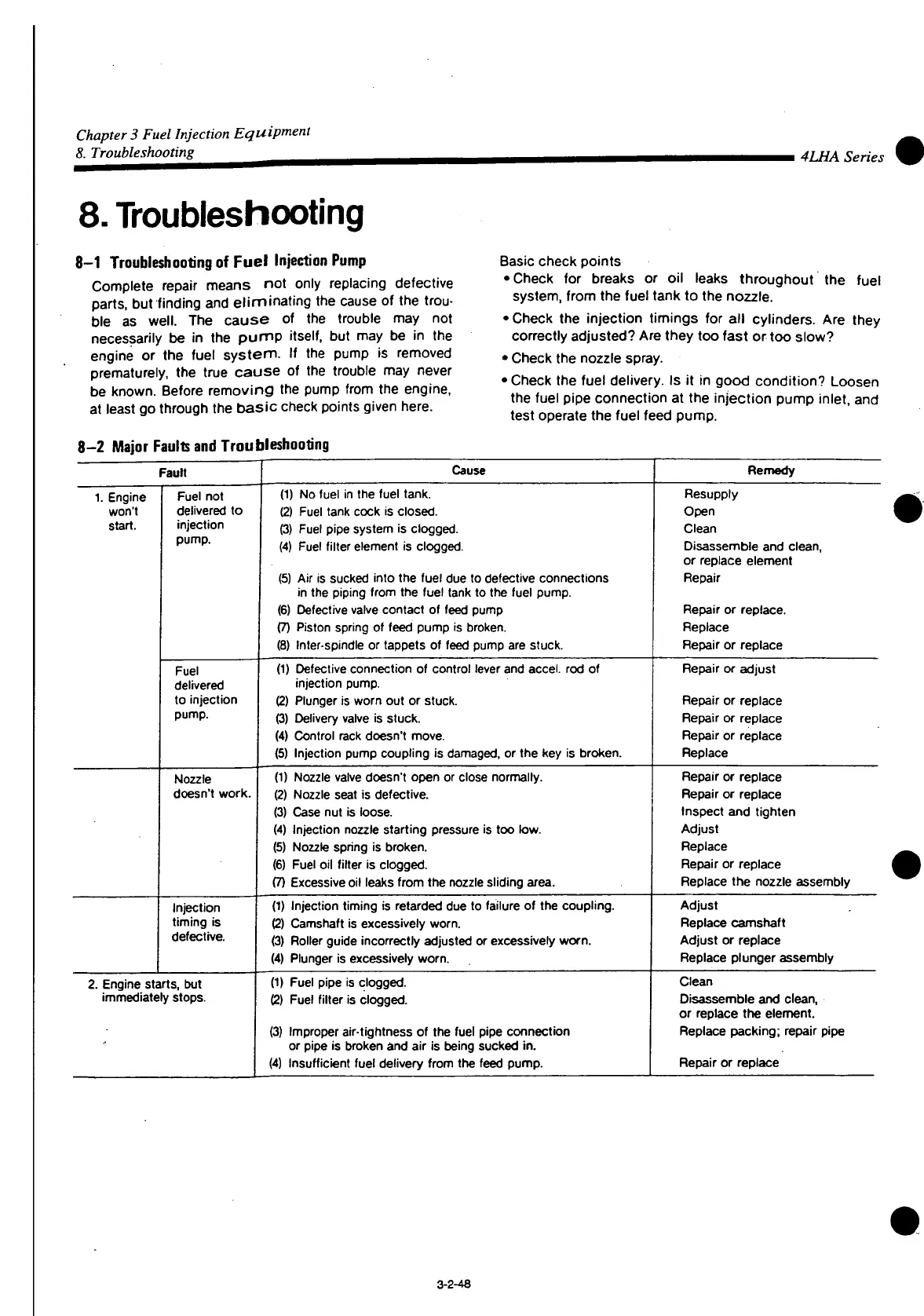

Fault

Cause

Remedy

1. Engine

won't

start.

Fuel

not

delivered to

injection

pump.

(1) No fuel in the fuel tank.

12) Fuel tank cock is closed.

(3) Fuel pipe system is clogged.

(4) Fuel

filter

element is clogged.

(5) Air is sucked

into

the fuel due to defective connections

in the piping from the fuel tank to the fuel pump.

(6) Defective valve contact of feed pump

(7) Piston spring of feed pump is broken.

(8) Inter-spindle or tappets of feed pump are stuck.

Resupply

Open

Clean

Disassemble

and clean,

or replace element

Repair

Repair

or replace.

Replace

Repair

or replace

1. Engine

won't

start.

Fuel

delivered

to injection

pump.

(1) Defective connection of control lever and

accel.

rod of

injection pump.

(2) Plunger is worn out or stuck.

(3) Delivery valve is stuck.

(4) Control rack doesn't move.

(5)

Injection

pump coupling is damaged, or the key is broken.

Repair

or adjust

Repair

or replace

Repair

or replace

Repair

or replace

Replace

Nozzle

doesn't work.

(1) Nozzle valve doesn't open or close normally.

(2) Nozzle seat is defective.

(3)

Case

nut is loose.

(4)

Injection

nozzle starting pressure is too low.

(5) Nozzle spring is broken.

(6) Fuel oil

filter

is clogged.

(7)

Excessive

oil leaks from the nozzle sliding area.

Repair

or replace

Repair

or replace

Inspect and tighten

Adjust

Replace

Repair

or replace

Replace

the nozzle assembly

Injection

timing is

defective.

(1)

Injection

timing is retarded due to failure of the coupling.

(2) Camshaft is excessively worn.

(3) Roller guide incorrectly adjusted or excessively worn.

(4) Plunger is excessively worn.

Adjust

Replace

camshaft

Adjust or replace

Replace

plunger assembly

2.

Engine starts, but

immediately stops.

(1) Fuel pipe is clogged.

(2) Fuel

filter

is clogged.

(3) Improper air-tightness of the fuel pipe connection

or pipe is broken and air is being sucked in.

(4) Insufficient fuel delivery from the feed pump.

Clean

Disassemble

and clean,

or replace the element.

Replace

packing; repair pipe

Repair

or replace

3-2-48

Loading...

Loading...