1.5 Motoman Safety

1-9

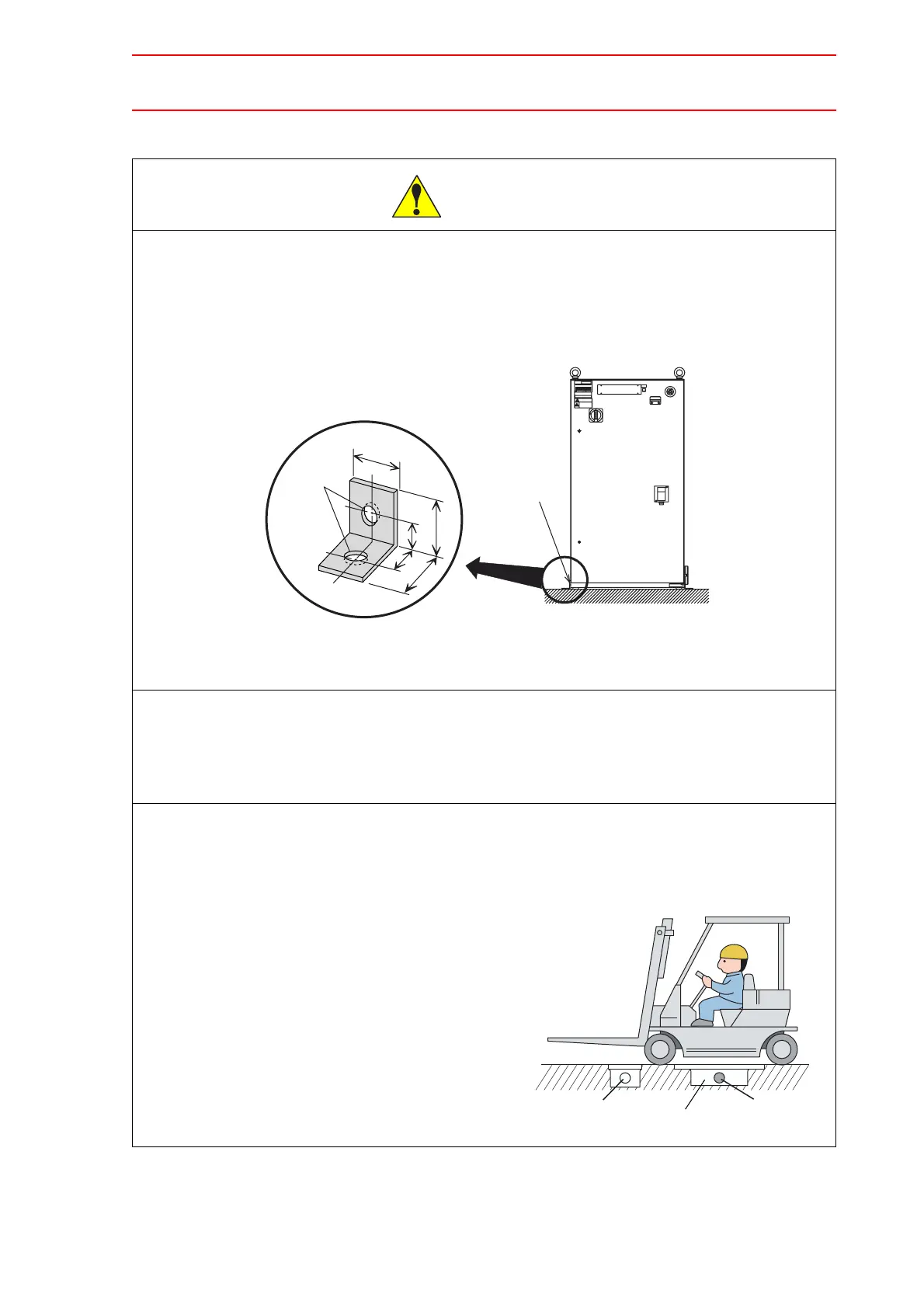

• Secure the position of the NX100 after setting up.

Attach the NX100 to the floor or rack, etc., using the screw holes on the bottom of the

NX100.

Failure to observe this caution could lead to injury or equipment damage if the NX100

should shift or fall.

• Be familiar with the connection diagram before wiring the NX100, and

perform the wiring in accordance with the connection diagram.

There is a danger of equipment damage or injury due to miswiring and unexpected move-

ment of the equipment.

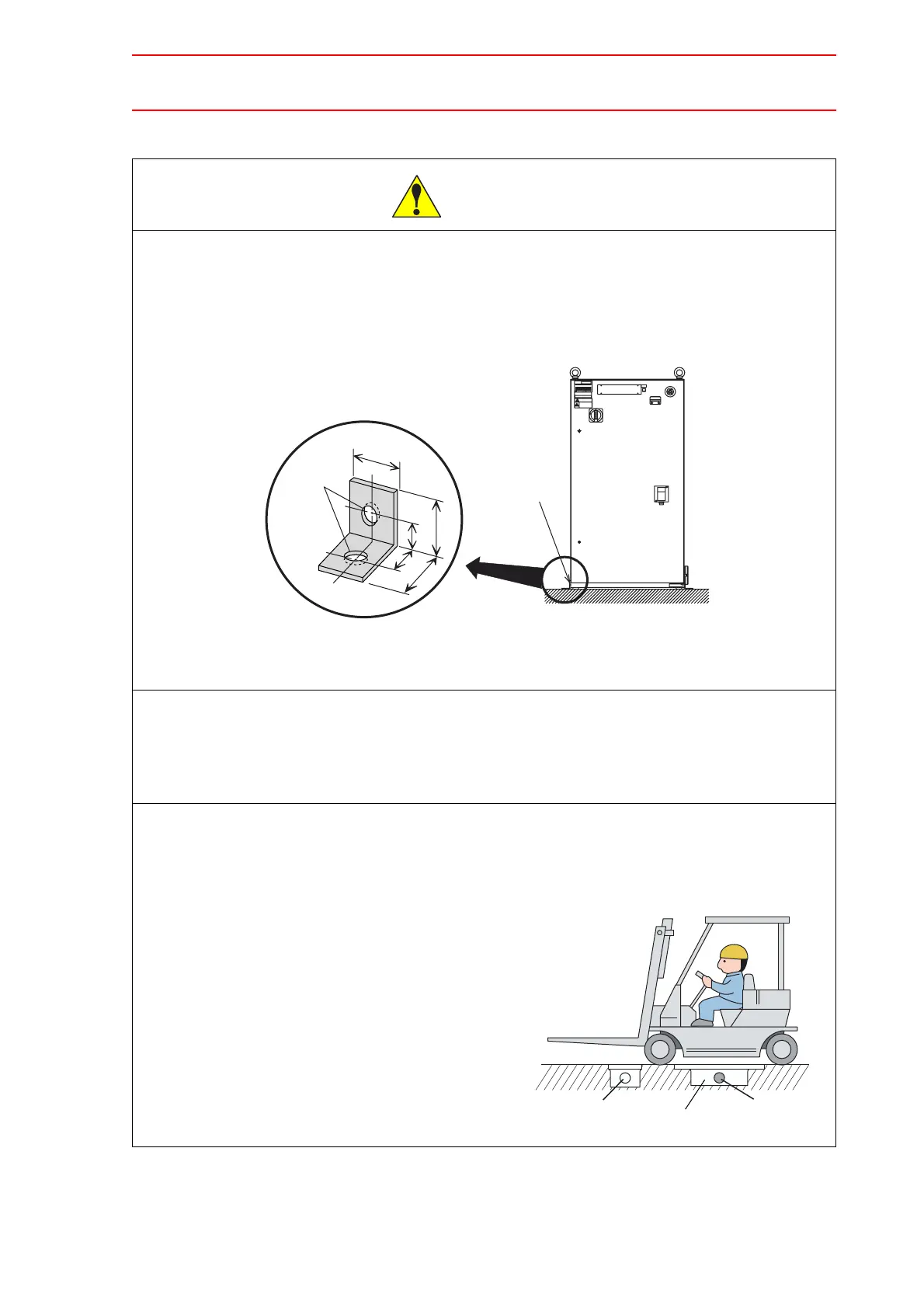

• Take precautions when wiring and piping between the NX100, manipula-

tor, and peripheral equipment. Run the piping, wiring, or cables through

a pit or use a protective cover, so that they are not stepped on by per-

sonnel or run over by the forklift.

CAUTION

Tapped!Holes!for

M10!Screws!on!

the!NX100!Side

40

30

50

30

50

(mm)

2-12!mm

diameter!

holes

kA

kVA

NJ2533-1

MADE!IN!JAPAN

TYPE

480V

SERIAL!No.

DATE

50/60Hz

INTERRUPT!CURRENT

POWER!SUPPLY

NX100/

ERCR-

3PHASE

NX100

NJ1530

ORDER NO.

SHOULD HAVE SAME ORDER NUMBER.

THE MANIPULATOR AND CONTROLLER

ENABLE

PLAY!!!MODE

WARNING

High!Voltage

with!power!ON.

Do!not!open!the!door

ON

O

F

F

M

E

N

C

G

R

E

O

S

T

P

E

Y

SAFETY

FIRST

Piping

Lead

Cable!Channnel

Operators and other personnel may stumble on

exposed wiring or piping. Cable damage can

cause unexpected manipulator motion resulting

in injury or property damage.

Loading...

Loading...