WFC- SC(H) Series .Installation

- 4 -

service, the Yazaki chiller-heater will not perform correctly on a continuous basis

without proper maintenance. Furthermore, always avoid placing the cooling tower at a

lower level than the chiller-heater. Such designs invariably lead to problems with

maintaining pumping stability.

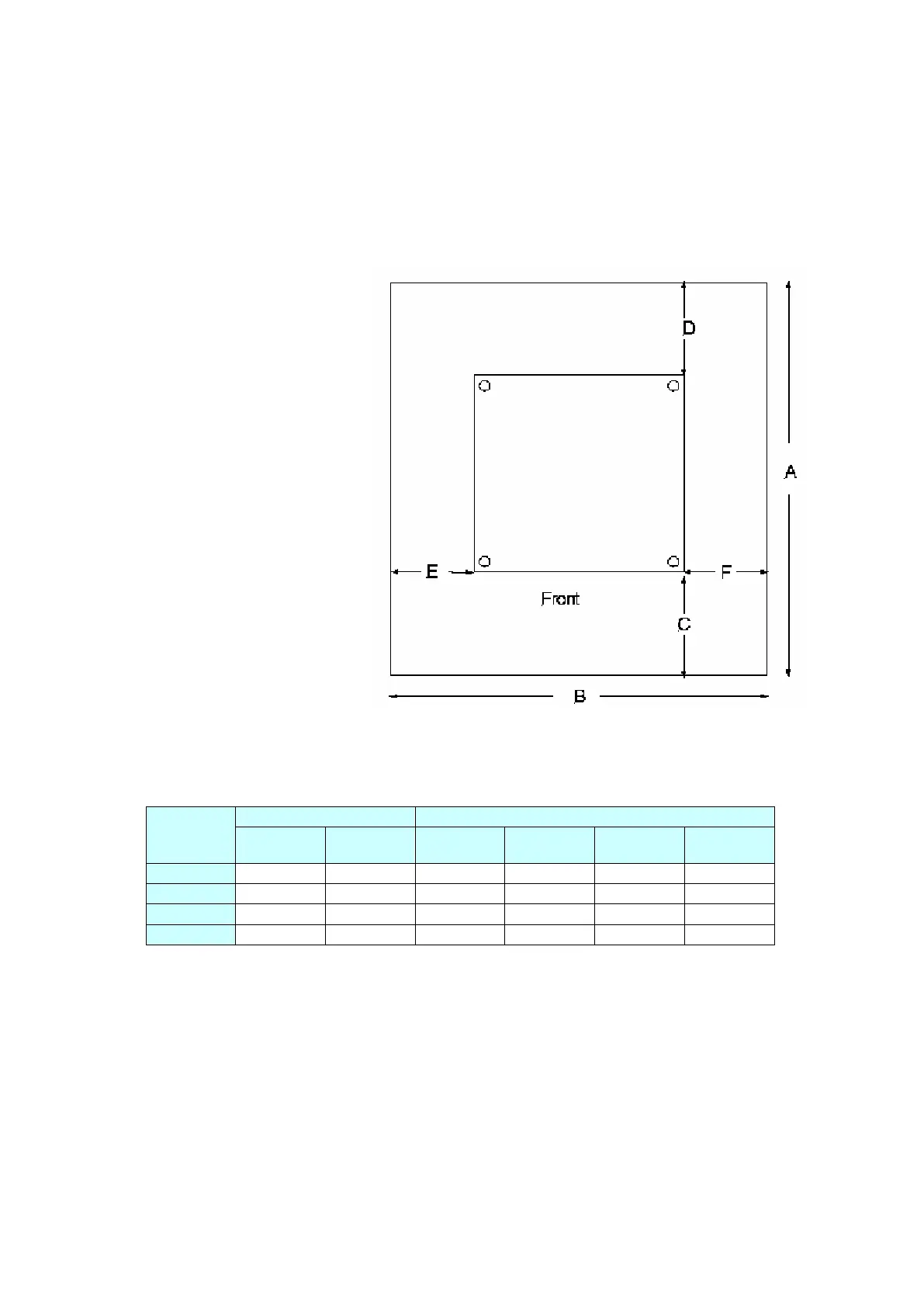

3.2 Minimum Maintenance Clearances

The minimum space and

clearance requirements

shown in figure 3 must be

provided around each

chiller-heater unit to

facilitate installation,

commissioning and

procedures in maintenance.

The clearances shown in the

table below apply to the CH-

K 30 through to the CH-

K100 machines. If the

system is a multi-module

configuration where chiller-

heaters will be placed side-

by-side, the clearances

recommended must still

apply. If the recommended

service clearances cannot be

provided as indicated, the

chiller-heater should not be

installed.

Figure 3

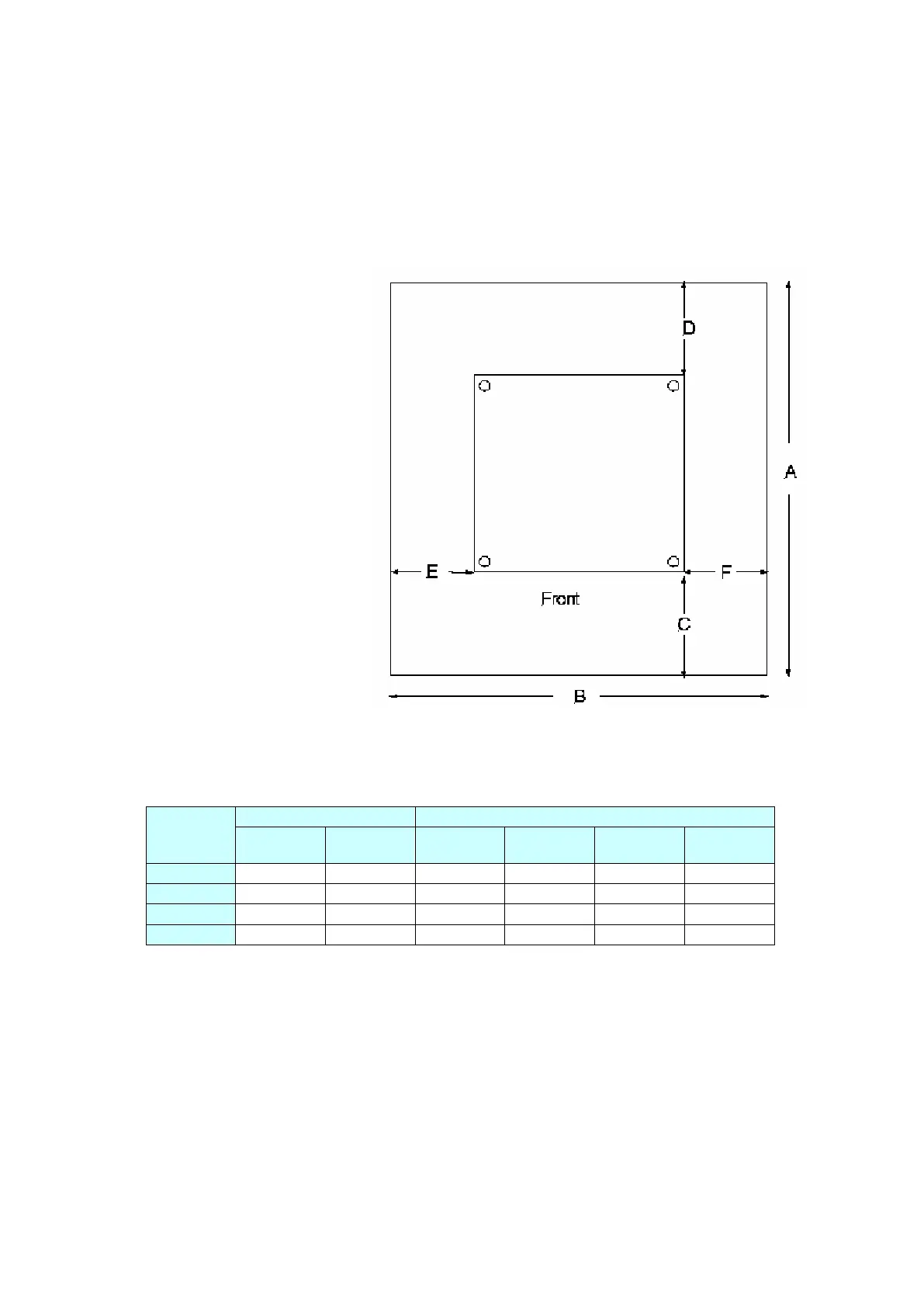

Table of Clearances

Installation Area Maintenance Clearances

Model

WFC-SC(H)

A

B

Front

C

Back

D

Left side

E

Right side

F

10

3,575 2,885 1,000 1,000 700 700

20

3,540 2,860 1,000 1,000 700 700

30

3,780 3,180 1,000 1,000 700 700

50

4,060 3,185 1,000 1,000 700 700

3.3 Foundation

Mount the absorption chiller-heater on a level foundation constructed of non-

combustible materials, capable of supporting the operating weight of the machinery.

This particularly applies to roofs, if that is where installation is contemplated.

Be sure the roof is able to support the chiller-heater, cooling tower, pumps and

associated piping (refer Section 1. Specifications for details). It is additionally

important that, if the equipment is to be placed on the roof of a building, it should be

located in a well drained area and at least two meters from the edge. A suitable

Loading...

Loading...