12

IM 12D06D05-01E

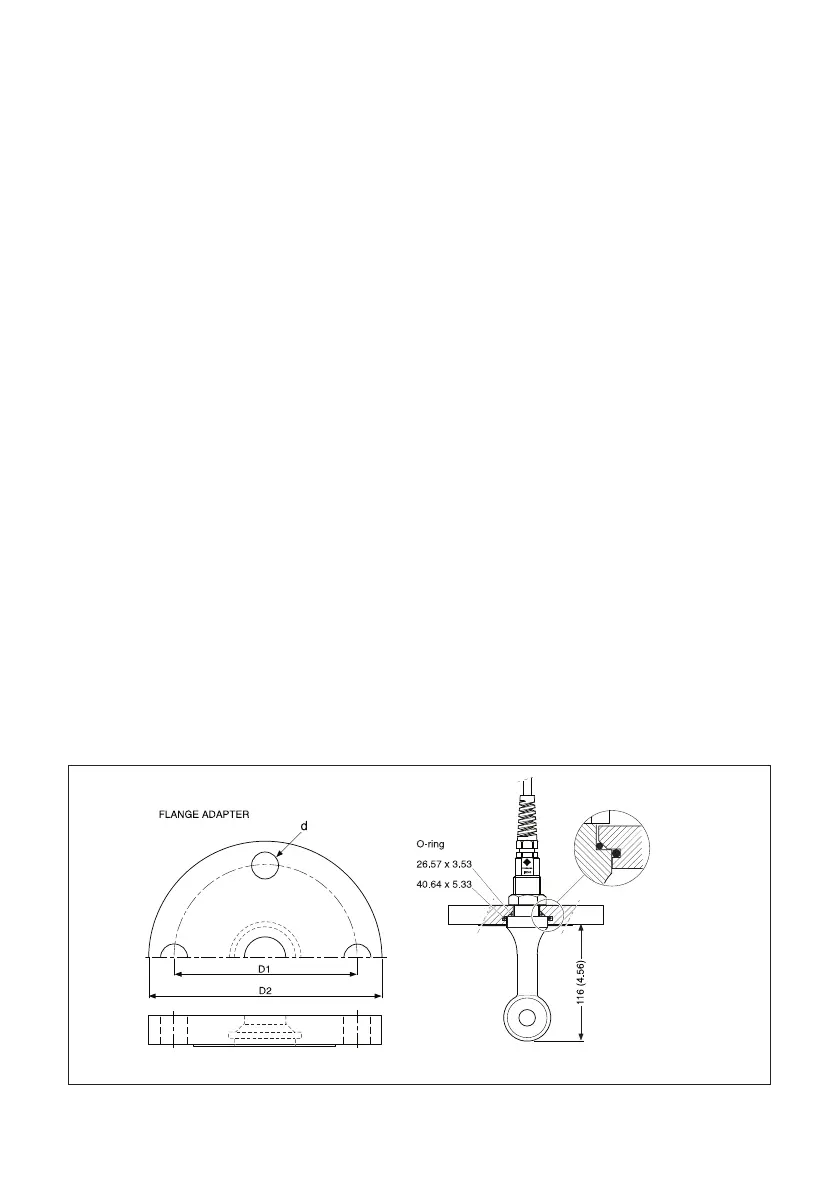

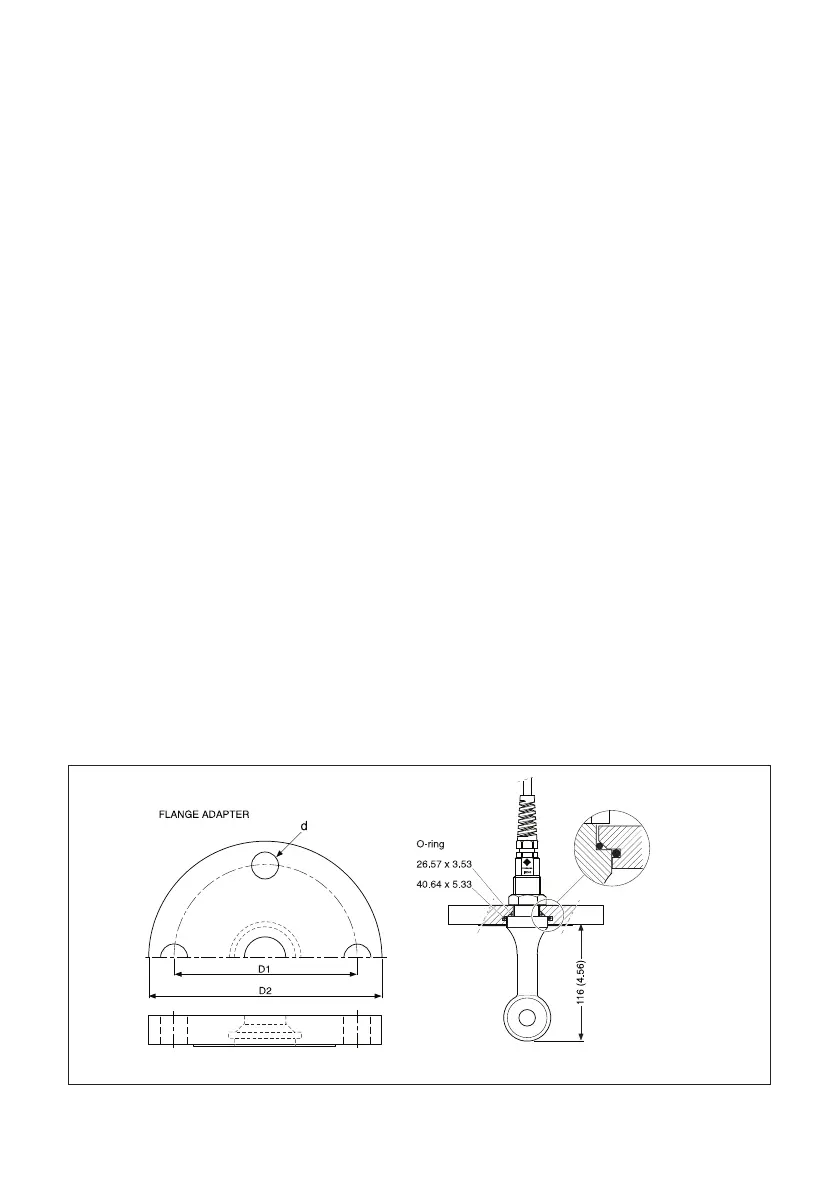

Figure 3-9a. Dimensions

It is necessary to use screening/shielding on

the output signal cables. Terminal 63 is used to

connect the shielding.

3-6. Wiring the sensor

3-6-1. General precautions

The sensor cable transmits low voltage, high

frequency signals and should be installed

separately from any high voltage, high cur rent

and/or power switching cables. This is to avoid

any unintentional cross talk or other kind of

interference of the conductivity meas ure ment.

3-6-2. Connecting the sensor cable to the

converter

1. To access terminals remove the front cov-

eroftheEXAxtISC450Gbyreleasingthe

4captivescrews.

2. Loosenthecableglandandpullthecable

in the connection compartment.

3. The sensor leads are numbered and the

leads must be connected to the ter mi nals

with the corresponding number, re fer to

Fig.3-4:thetemperaturecompensator

with 11/12

- the drive coil with 15/16

- the receive coil with 13/17

Terminal14isforconnectionoftheshield.

4. ScrewthecableglandtighttoensureIP66

(NEMA4X)environmentalprotection.An

optional protection hose (flexible con duit)

is available for additional me chan i cal pro-

tec tion of the sensor cable.

3-6-3. Installation of the sensor

TheModelISC40isa“doughnut”shapedsen-

sor. Preferably, the process will flow through

the hole of the donut with the temperature com-

pensatorup-stream.Forminimalobstructionof

the flow and for accurate measurement without

the need for calibration of the cell constant, the

process will flow freely around the doughnut,

allowingaminimumdistanceof25mm(1”)

between doughnut and process piping (d).

The sensor is provided with a gasket and

retainingnut.Thisallows“bulkheadmounting”

in tank wall or standard flange through a hole of

27mm(1.1”)diameter(A).Theinsertionis125

mm under the flange.

Two flats are provided with wrench size 20 mm

(0.8”)toalloweasymountingandalignmentof

the sensor. The model identification on one flat

alignswiththe“up-stream”positionofthesen-

sor.ForOn-linemountingadaptersareavail-

ableforstandard2”processconnection(Gas

thread,NPT,ANSI-flange,DIN-flange).

Forby-passmeasurementflowfittingsare

available in polyporpylene, polyvinylidene flour-

ideandStainlessSteel.

Formeasurementsinopenductsorvesselsan

immersionfittinginCPVCorStainlessSteelis

available.

Foreasywiringthesensormustbelocated

within5m(15”)fromtheconverterusingthe

integral sensor cabling.

Loading...

Loading...