24

IM 12D06D05-01E

5-6. mA output setup

The general procedure is to first define the

function (control, output, simulate, off) of the

output and second the process parameter

associated to the output. Available process

parametersdependonselected“sensortype”

and“measurementsetup”.

Off :Whenanoutputissetoffthe

output is not used and will give an

outputof4mA.

Control : A selection of P- PI- or PID control

Manual :Staticoutputrequiredtomaintain

reset equilibrium state with setpoint.

Direction : Direct

If the process variable is too high

relativetotheSP,theoutputof

the controller is increased (direct

action).

: Reverse

If the process variable is too high

relativetotheSP,theoutputofthe

controller is decreased (reverse

action).

Output :

Linearornonlineartableoutput.

The table function allows the configu-

ration of an output curve by 21 steps

(5%intervals).Inthemainmenu

concentration can be selected to set

the concentration range.

Simulate :Percentageofoutputspan.

Normal span of outputs are limited

from 3.8 to 20.5 mA

Failsafe :ContactS4isprogrammedasa

fail-safe contact.

BurnLoworHighwillgiveanoutputof3.6

resp.21mAincaseofFailsituation.

Note! When leaving Commissioning, Hold

remains active until switched off

manually. This is to avoid inappropriate

actions while setting up the

measurement.

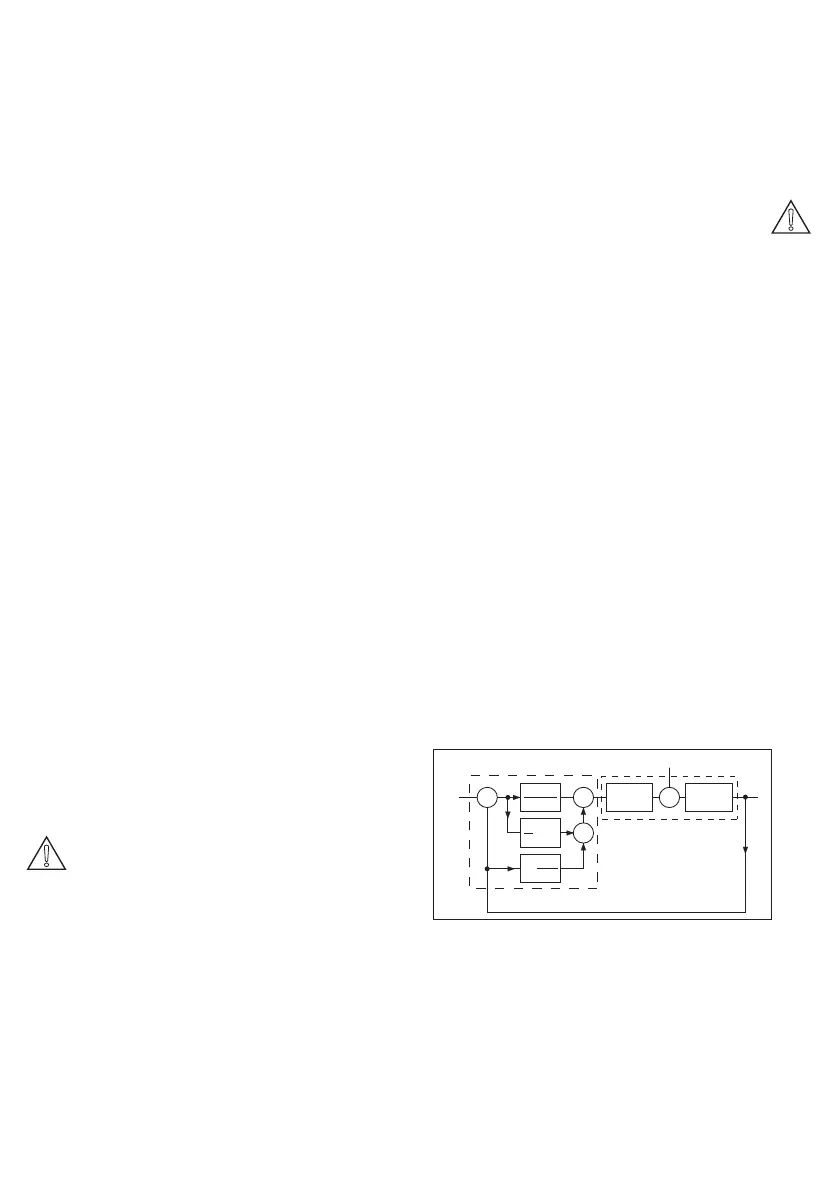

Proportional control

Proportional Control action produces an output

signal that is proportional to the difference

betweentheSetpointandthePV(deviationor

error). Proportional control amplifies the error to

motivate the process value towards the desired

setpoint. The output signal is represented as a

percentageofoutput(0-100%).

Proportional control will reduce but not

eliminate the steady state error. Therefore,

proportional Control action includes a Manual

Reset. The manual reset (percentage of output)

is used to eliminate the steady state error.

Note! Any changes (disturbances) in the

process will re-introduce a steady state

error.

Proportional control can also produce exces-

sive overshoot and oscillation. Too much gain

may result in an unstable- or oscillating proc-

ess. Too little gain results in a sustained steady

state error. Gain = 1/Range. [PV units]

Integral Control

Integral control is used to eliminate the steady

state error and any future process changes.

It will accumulate setpoint and process (load)

changes by continuing to adjust the output

untiltheerroriseliminated.Smallvaluesof

integral term (I-time in seconds) provide quick

compensation,butincreaseovershoot.Usually,

the integral term is set to a maximum value that

provides a compromise between the three sys-

tem characteristics of: overshoot, settling time,

and the time necessary to cancel the effects of

static loading (process changes). The integral

term is provided with an anti windup function.

When the output of PI portion of the controller

isoutsidethecontrolrange(lessthan-5%or

greaterthan105%),theI-partisfrozen.

SP

PV

e

+

-

+

+

+

+

+

-

e

Range

ºe dt

1

T

i

T

d

dPV

dt

Process

Controller

Actuator

Process

Figure 5-1. Control Diagram

Derivative control

The control acts on the slope (rate of change)

of the process value, thereby minimizing

overshoot.Itprovides“rate”feedback,resulting

in more damping. High derivative gains can

increase the rizing time and settling time. It is

difficult to realize in practice because differen-

tiationleadsto“noisy”signals.

Loading...

Loading...