52

IM 12D06D05-01E

APPENDIX 3

Calibration solutions for conductivity

Note!

This section should be read in conjunction with the calibration section (Chapter 6) and the mainte-

nance section (Chapter 7). The calibration (cell constant) of a sensor does not change unless the

sensor is damaged.

Itcanalsoappeartochangebecauseofcoatingoftheelectrodes,orpartialblockage.Because

these changes should be handled as described in the maintenance section, it does not make

sensetoregularlyrecalibratetheISC450G.

A calibration check, however, is another matter. When the objective is clearly defined as a diagnos-

tic exercise a regular check can bring an extra level of security and confidence to the measure-

ment.

Sensordamage,and/orcoatingscanbedifficulttoseeandthecalibrationcheckcanconfirmtheir

presence, by a deviation from the known solution conductivity. The remedial action should be to

clean the sensor, and carefully check for blockage or damage (not simply to recalibrate).

Higher conductivity solutions should be used where possible. The lower the conductivity of the test

solution, the easier it is to contaminate. Carbon dioxide from the air can be quickly absorbed to

causeanerror.Allcontainersmustbesuitablyclean,andallmaterialssuitablypure.Outsideofa

well-equipped laboratory these conditions are hard to meet.

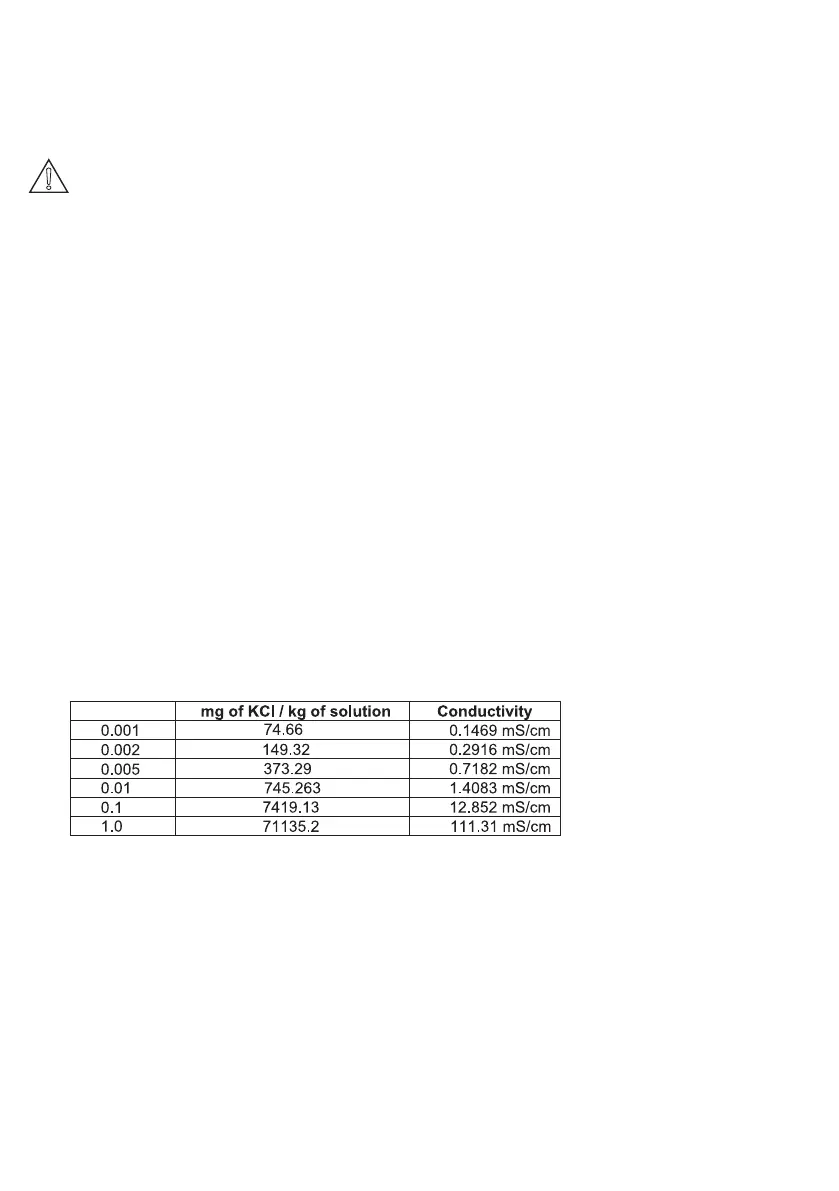

EXAxtISC450GisprogrammedwiththefollowingtableofconductivityofPotassiumChloride

(KCl)solutionsat25°C.ThisisusedintheAutomaticCellConstantsettingcalibrationfeature.

(Seechapter6oncalibration)ThetableisderivedfromtheStandardslaiddownin“International

RecommendationNo.56oftheOrganisationInternationaledeMétrologieLegale”.

Table 11-2. KCl values at 25 °C

Loading...

Loading...