<4. Applications>

4-10

TI 11M12A01-01EAll Right Reserved Copyright © 2004, Yokogawa Electric Corporation

Mar. 14, 2017-00

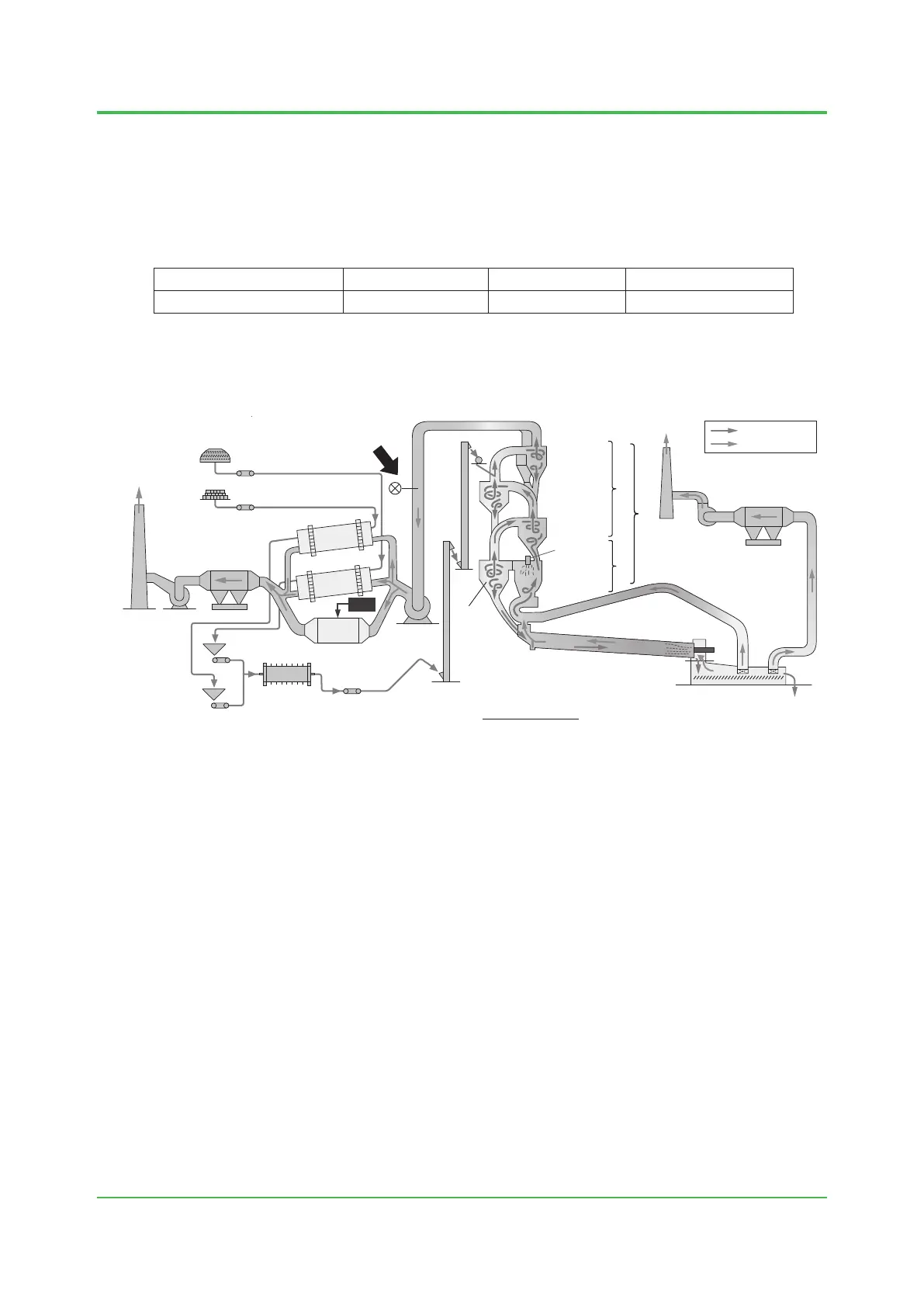

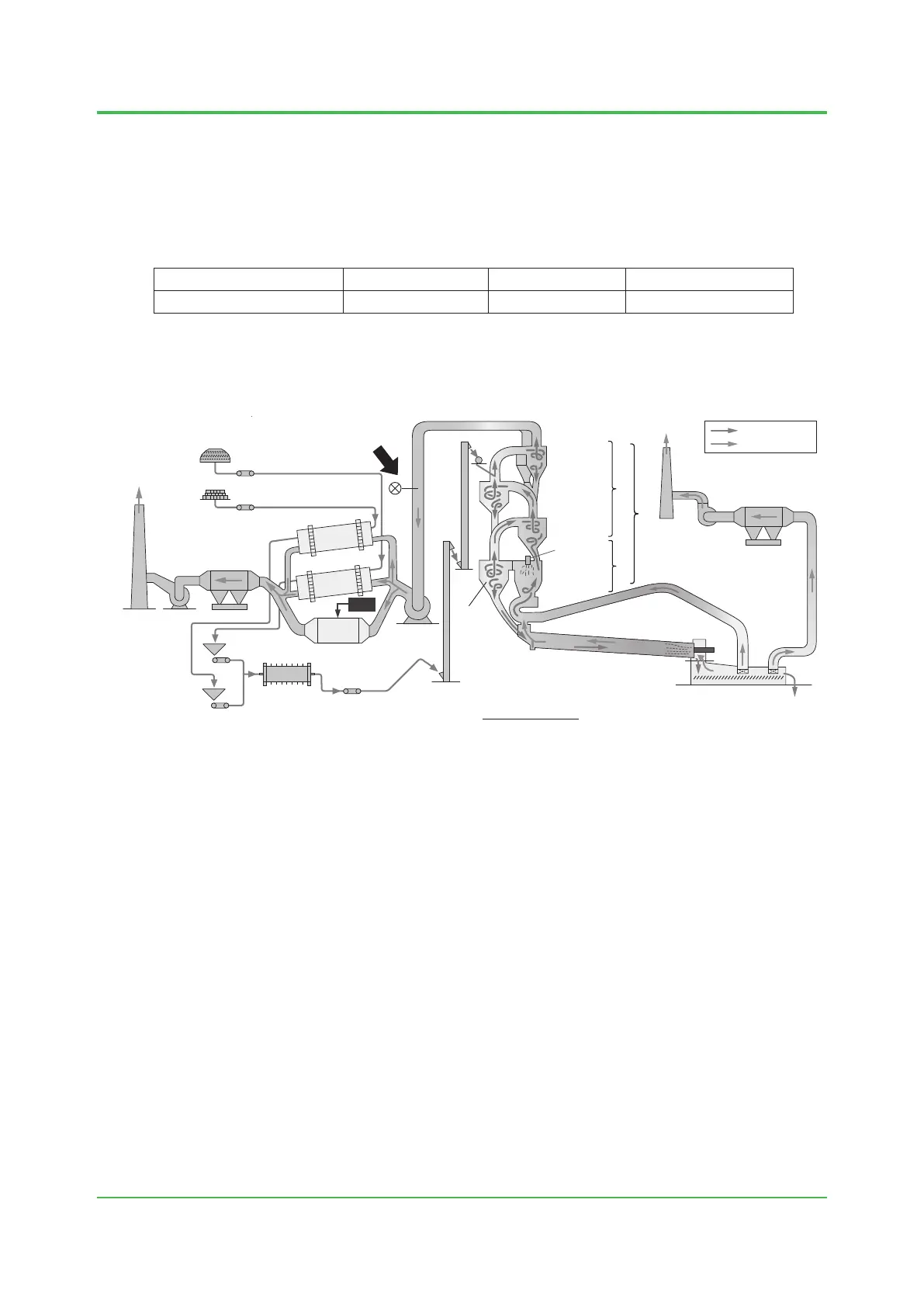

(2) Cement kiln (cyclone outlet gas)

Cement production consumes approximately 100 liters or more of fuel (heavy oil) per ton of

cement. Thus, combustion management by means of zirconia oxygen analyzers has become a

critical element.

There are cases in which O

2

, CO, and CO

2

measurements are performed using a sampling

system at the kiln outlet.

Sample point System type Detector Objective

Cyclone outlet L2, L3 D4, (D3) Combustion monitoring

Cement kiln

Gas temperature: 350 to 400°C

Gas pressure: –3 to 5 kPa

Dust: ≧200 g/Nm

3

CO: ≧0.2%

F0410.ai

NSP Cement Kiln

Exhaust Gas

Stack

Clay

Limestone

Limestone

dryer

Clay

dryer

Water

Stabilizer

Mill

: Material flow

: Gas flow

Burner

Air-draft

Combustion

Furnace

Bucket Elevator

Rotary kiln

Exhaust gas

Electric Precipitator

Cooler

Exhaust

Burner

Clinker cooler

Clinker

Electric Precipitator

Stage 4

Cyclone

Stage 1

Cyclone

Stage 2

Cyclone

Stage 3

Cyclone

SP

FF

SF

Secondary Air Duct

Loading...

Loading...