<2. Installation Guide>

2-2

TI 11M12A01-01EAll Right Reserved Copyright © 2004, Yokogawa Electric Corporation

Mar. 14, 2017-00

Installation Site of the Converter (in case of ZR402G)

1. Allows the operator to easily read the display and operate the keys.

2. Easy access for inspection and maintenance.

3. Ambient temperature does not exceed 55°C, and temperature variations are minimal.

4. Humidity is moderate (40 to 75% RH) and no corrosive gases are present.

5. Minimum vibration.

6. Near to the detector.

7. Not exposed to direct sun light.

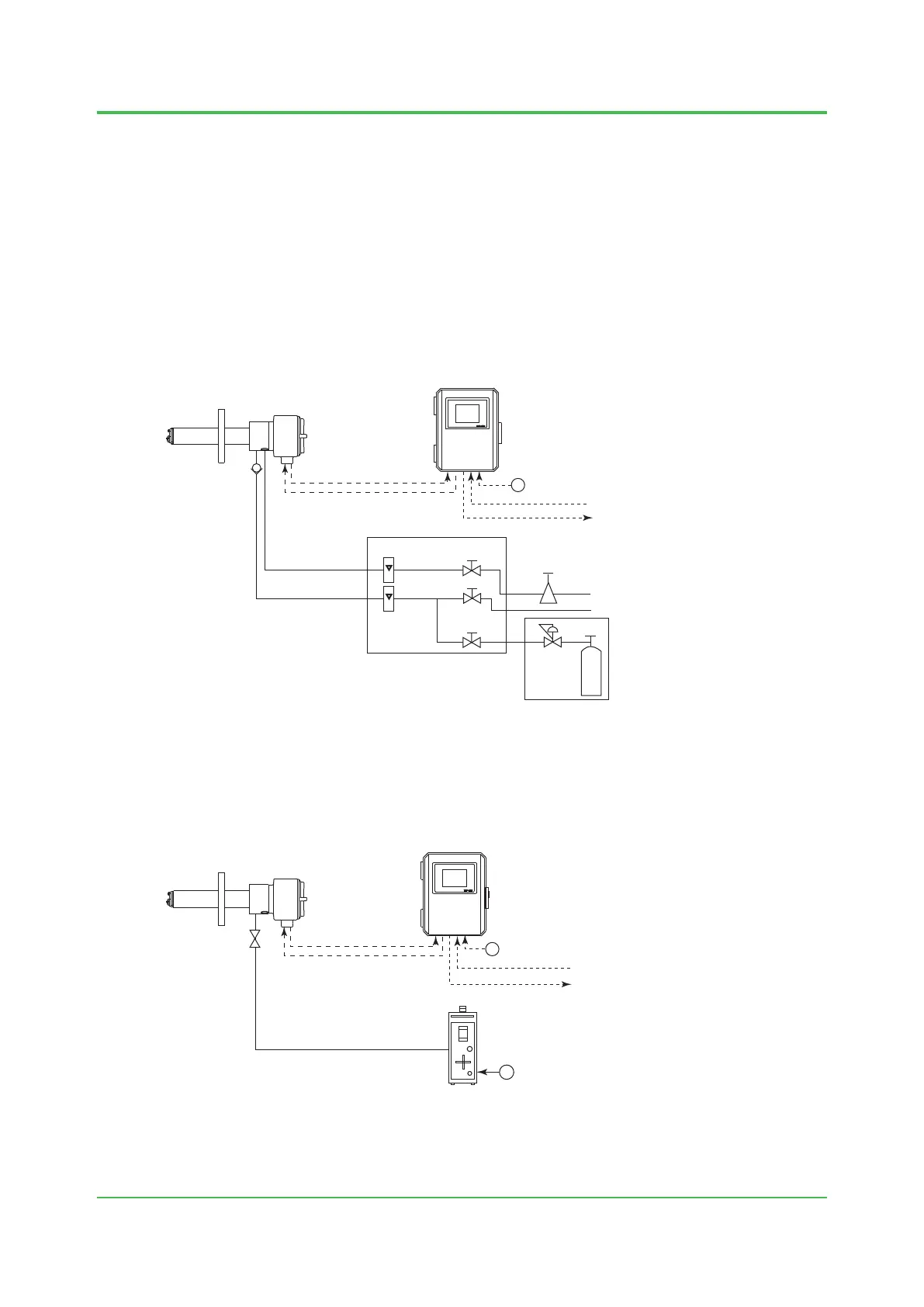

Instrument air is used as the reference gas

EXA

ZR402G

~

ZR402G Converter

Check valve

or Stop valve

ZA8F Flow Setting Unit

ZR22G Detector

100 to

240 V AC

Air Set

Instrument air

Calibration gas

Reference gas

Flowmeter

Needle

valve

Zero gas cylinder

Span gas

Contact input

Analog output, contact output

(Digital output HART)

Signal

(6-core shield cable)

Heater (2-core)

F0202.ai

1) Install the stop valve or check valve securely so that the gas does not leak.

2) Use the ZA8F flow setting unit and zero gas cylinder.

3) Use a shielded cable for the signal line.

Regulator

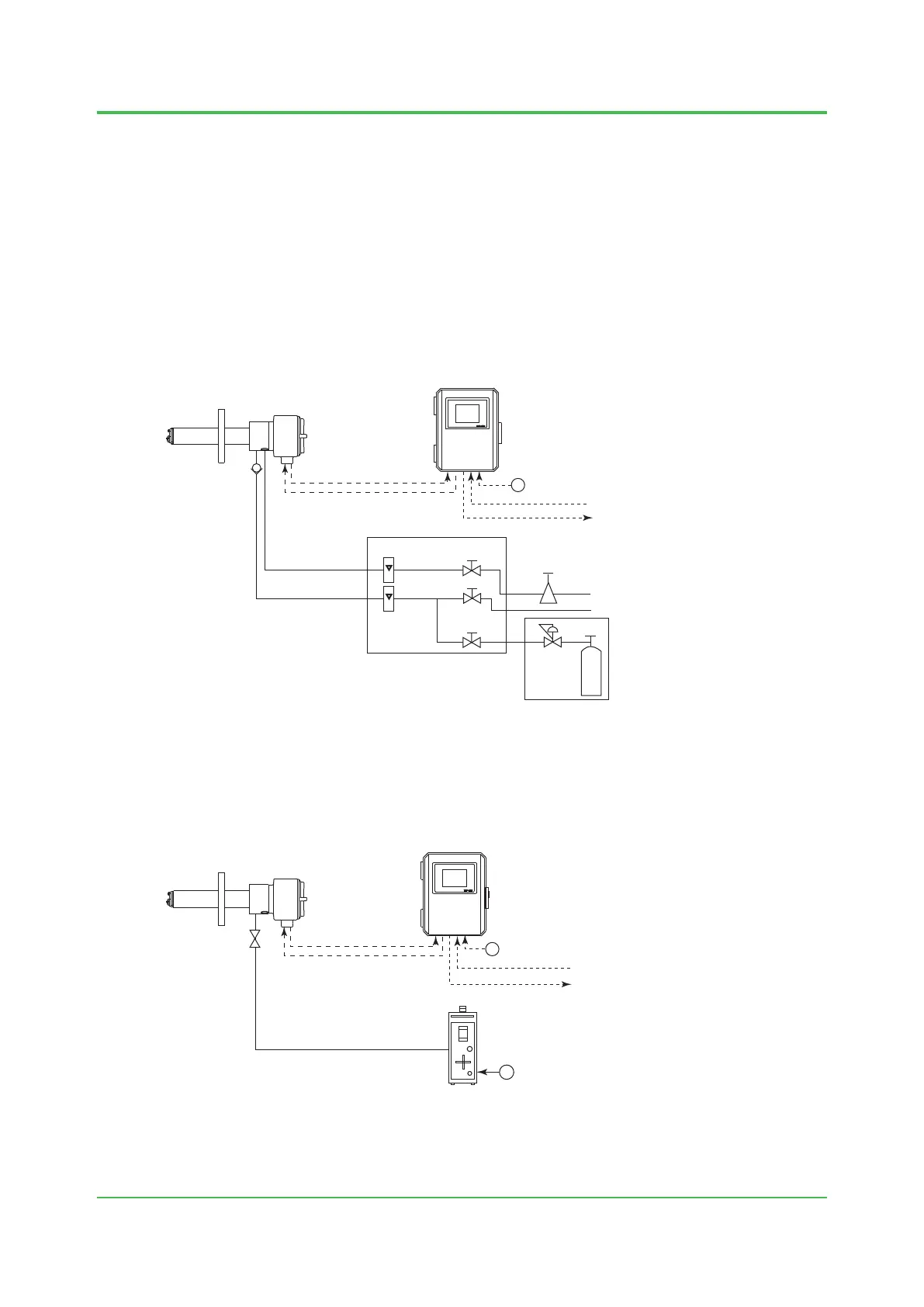

Ambient air is used as the reference gas

EXA

ZR402G

F0203.ai

~

~

ZR22G Detector

1) Install the stop valve securely so that the gas does not leak.

2) Use the ZO21S standard gas unit.

3) Use a shielded cable for the signal line.

ZR402G Converter

Stop valve

Calibration gas

ZO21S Standard gas unit

100 to

240 V AC

Contact input

Analog output, contact output

(Digital output HART)

Signal

(6-core shield cable)

Heater (2-core)

Loading...

Loading...