IM 12B07D02-01E

Installation and wiring 3-7

3-5. Wiring the sensor system

3-5-1. Impedance measurement jumper settings

NOTE:

It is important to decide first which application and which settings are appropriate for the

installation. This decision is best made before the jumpers are installed, because the cables will

rest beside the jumpers in their installed positions.

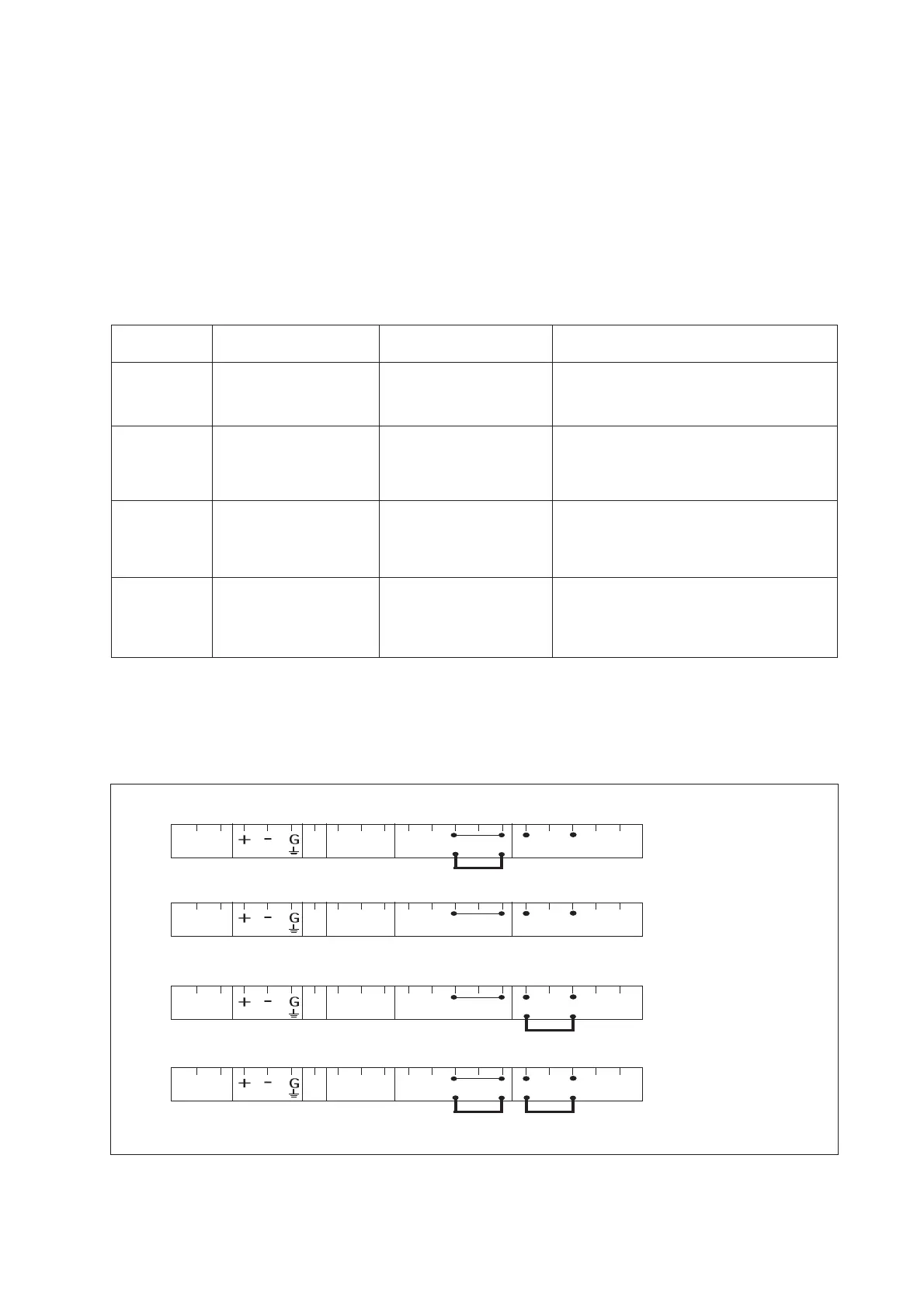

Table 3-1. Impedance measuring jumpers

Figure no. Jumper Settings Jumper Settings Application & Sensor Connections

Input #1 Input #2

1 High Impedance Low Impedance Normal pH sensors

Glass sensor on Input #1

Reference sensor on Input #2

2 High Impedance High Impedance Special electrodes using

2 glass sensors

(e.g. Pfaudler 18)

3 Low Impedance High Impedance ORP (pH compensated) and/or rH

metal sensor on Input #1

pH glass (as reference) on Input #2

4 Low Impedance Low Impedance ORP (Redox measurement)

metal sensor on Input #1

Normal reference on Input #2

For convenience insulated jumper links are provided. Ordinary wire links can also be used, and are just

as effective.

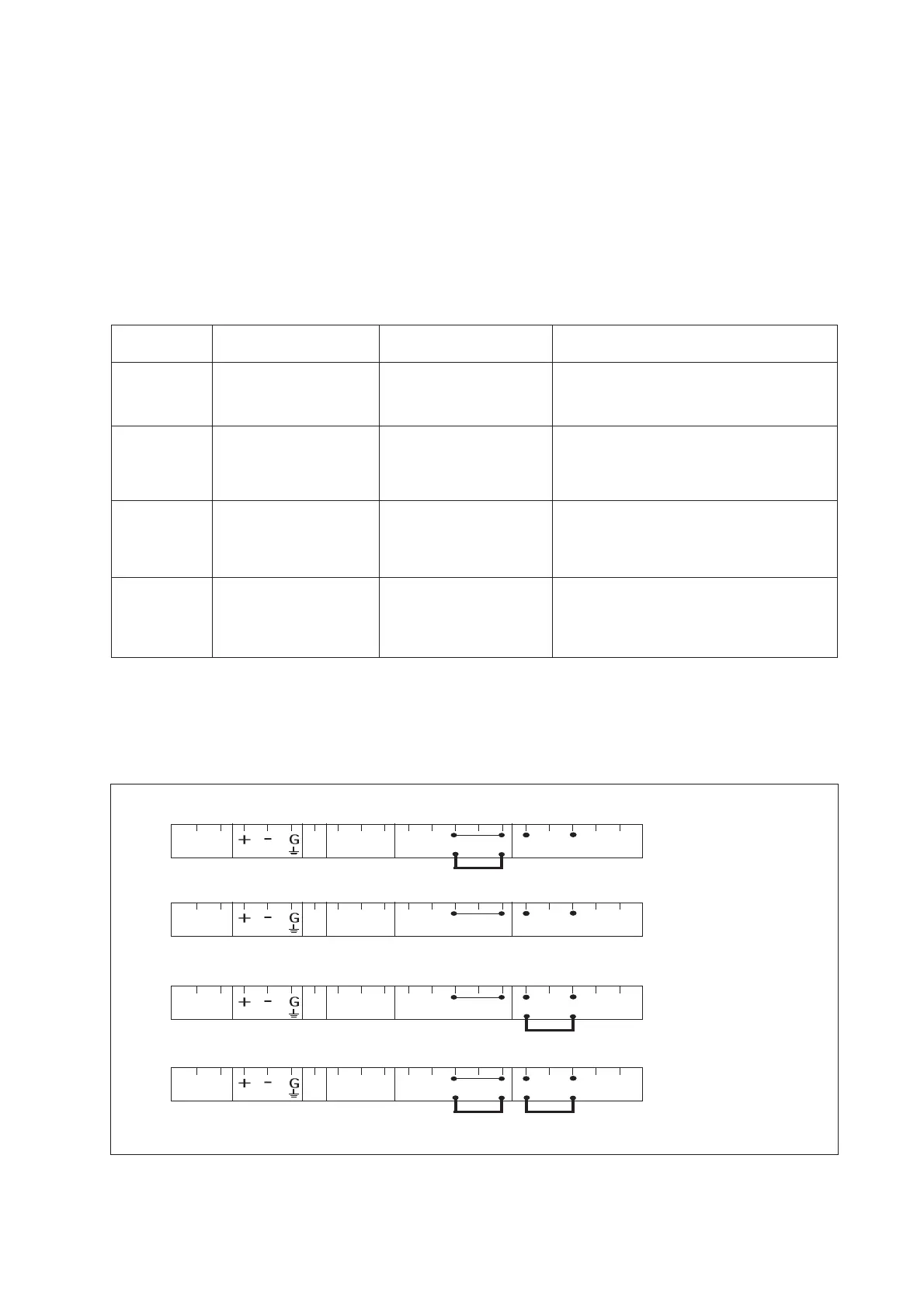

The following four jumper figure illustrations (figure 3-8) show the jumper positions related to the figure

numbers in the above table.

11 12 14 17 13 15 16

HIGH IMPLOW IMP

SUPPLY TEMP LE

INPUT 2

INPUT 1

11 12 14 17 13 15 16

HIGH IMPLOW IMP

SUPPLY TEMP LE INPUT 2 INPUT 1

11 12 14 17 13 15 16

HIGH IMPLOW IMP

SUPPLY TEMP LE

INPUT 2

INPUT 1

11 12 14 17 13 15 16

HIGH IMPLOW IMP

SUPPLY TEMP LE

INPUT 2 INPUT 1

1

2

3

4

Setting on shipment

Fig. 3-8. Jumper positions

Loading...

Loading...