IM 01C50B01-01E

6-1

6. MAINTENANCE

6. MAINTENANCE

6.1 General

Each component of this instrument is configured in

units to make maintenance easier.

This chapter contains disassembly and assembly

procedures associated with calibration, adjustment and

part replacement required for maintenance of the

affected instrument.

IMPORTANT

1. Maintenance of this instrument should be

performed in a service shop where the neces-

sary tools are provided.

2. Handling the CPU assembly

Some of the parts contained in the CPU

assembly are susceptible to static electricity

damage. Before performing maintenance, use

a ground wrist band or other antistatic mea

sures, and avoid touching the electronic

components and circuits with bare hands.

When removed from the instrument, keep the

CPU assembly in an antistatic bag.

6.2 Calibration

This instrument is fully factory-tested and is guaran-

teed for the intended accuracy, eliminating the need for

calibration. When calibration needs to be varified, the

following equipment and calibration procedure is

recommended.

6.2.1 Selection of Equipment for Calibra-

tion

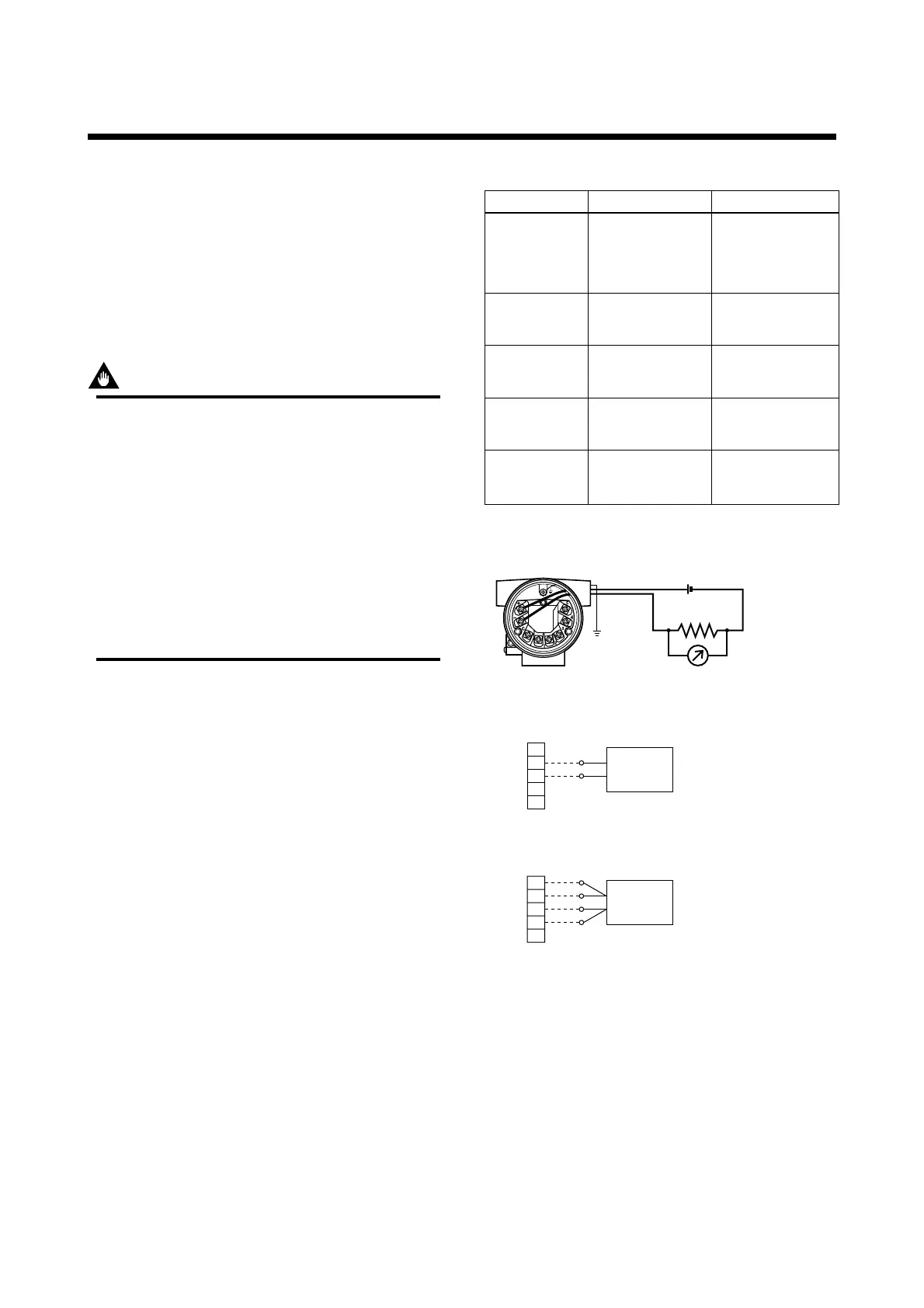

Table 6.1 lists the equipment required for calibration.

The calibration equipment traceable to a verifying

agency standard should be used.

6.2.2 Calibration Procedure

To conduct calibration required to evaluate the uncer-

tainty while using the instrument, follow the steps

below:

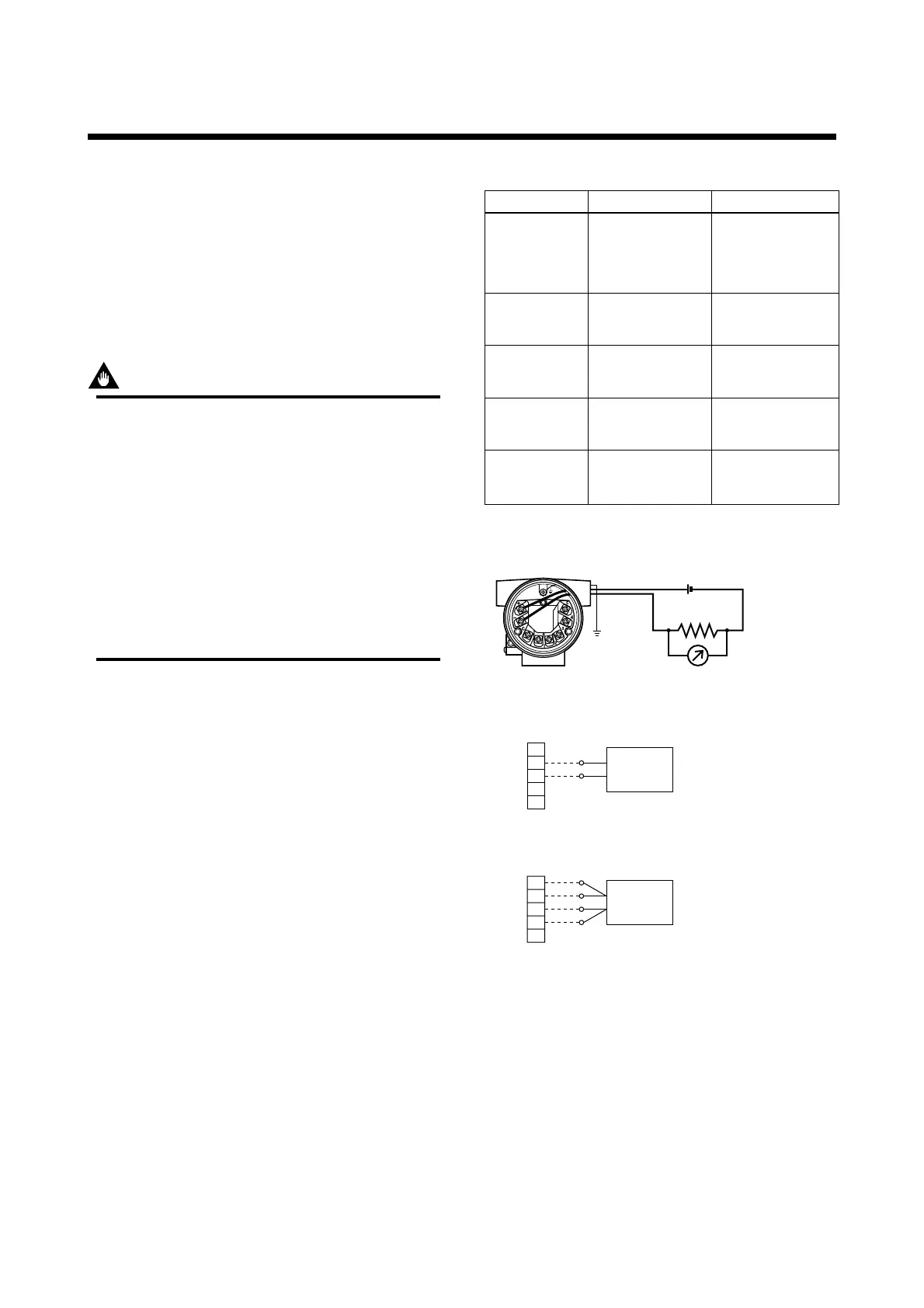

1. In accordance with the example wiring shown in

Figure 6.1, connect each equipment and initiate

warm up. Lay wiring on the input side according to

the sensor to be used.

Table 6.1 Calibration Equipment List

T0601.EPS

Power supply

2792 type standard

resistor

(250⍀ ±0.005%)

Voltmeter

Universal

calibrator

Variable resistor

SDBT, SDBS

type distributor

Model 1271 digital

multimeter

(accuracy: ±0.002%)

Model 9100 type

Load resistance

4 to 20mA DC

(Output voltage:

26.5±1.5V, drop by

internal 250⍀

resistance included)

For 4 to 20mA DC

For 4 to 20mA DC

signal

For calibration of

DC voltage and

thermocouple

For calibration of

thermometer resistor

(RTD) input

Name Recommended Remark

279301 type 6-dial

variable resistor

(accuracy: ±0.005%)

F0601.EPS

1

2

3

4

5

1

2

3

4

5

(A)

(B)

(B)

(A)

a. Wiring of power supply and output

b. Example of wiring for thermocouple

or DC voltage input

(when 1 input type is used)

+ Output signal

–

Load

resistance

DC voltage generator

Voltmeter

c. Example of wiring for thermometer

resistor 4-core type

(when 1 input type is used)

Variable resistor

(+)

(–)

Figure 6.1 Example of Wiring for Calibration Equipment

2. For DC voltage input

With a voltage generator, deliver input signals

corresponding to 0, 25, 75, or 100% of the input

span to the temperature transmitter. Measure the

resulting input signal with the voltmeter (digital

multimeter) and check the output value relative to

the input value.

Loading...

Loading...