IM 01C50B01-01E

6-2

6. MAINTENANCE

3. For thermocouple input

Since this instrument is equipped with a reference

junction compensating function, use a reference

junction compensating function in universal

calibrator in order to compensate for this function

upon calibration. According to the reference

milivolt table for thermocouple, obtain milivolt

corresponding to 0, 25, 50, 75, or 100% of the

span, and use that power as the input value, then

deliver it from the universal calibrator to the

temperature transmitter. Measure the resulting

output signal with the voltage meter (digital

multimeter) and check the output value relative to

the input value.

4. Thermometer resistor (RTD)

Using a thermometer resistor as input, calibration of

the temperature transmitter is carried out via a 4-

core wire connection.

As defined the reference resistor value table of the

thermometer resistor (RTD), obtain resistance

values corresponding to 0, 25, 50, 75 or 100% of

the span, and use the obtained resistance as the

input value, then deliver it to the temperature

transmitter by means of a variable resistor. Measure

the resulting output signal with the voltmeter

(digital multimeter) and check the output value

relative to the input value.

5. In Steps 2 through 4, if the output signal deviates

from the given range of accuracy when a given

input signal is delivered, adjust the output using the

handheld terminal. For details of how to adjust the

output, refer to the additional references, “BRAIN

Protocol” IM 01C50T03-01E or “HART Protocol”

IM 01C50T01-01E and the instruction manual for

each terminal.

6.3 Disassembly and Assembly

This section details the procedure for part replacement

or disassembly and assembly of each component

depending on the maintenance process.

Before starting disassembly and assembly work, turn

off the power, and use a tool suited to the associated

work.

Table 6.2 lists the tools required for disassembly and

assembly of the instrument.

Table 6.2 Tools for Disassembly and Assembly

T0602.EPS

Tool name Quantity Remark

Phillips screwdriver 1

Standard screwdriver 1

Hexagonal wrench 1

Crescent wrench 1

Torque wrench 1

Box wrench 1 For M10 screw

Box screwdriver 1

Forceps 1

CAUTION

Precautions for CENELEC and JIS Flame-

proof Type Transmitters

• For a withstand flameproof type transmitter, as

a rule, move the transmitter to a non-hazardous

location, then proceed with maintenance and

restore the instrument to the original condition.

• For a withstand CENELEC and JIS flameproof

type transmitter, turn the lock bolt (hexagon

socket bolt) clockwise with a wrench for hexa-

gon head, unlock and remove the cover. When

installing the cover, it is the must to turn the

lock bolt counterclockwise and lock the cover

(locked to a torque of 0.7 Nm).

• For a withstand flameproof type transmitter, in

no case should the user be allowed to modify

the transmitter. Therefore, no user is allowed to

add a built-in indicator, or use the transmitter

with the indicator removed. Contact us for any

modification.

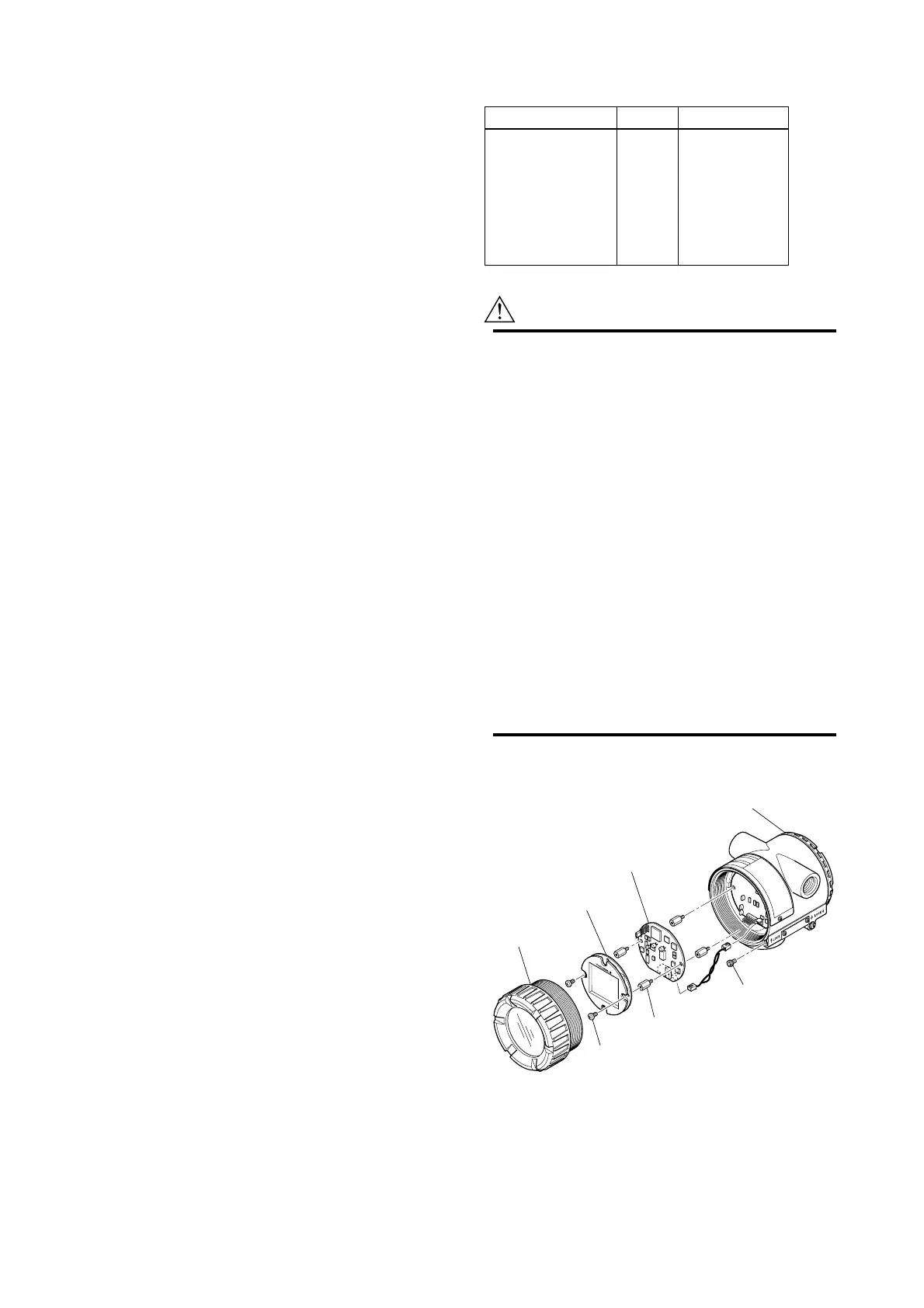

F0602.EPS

Ter minal cover

Lock bolt

CPU assembly

Stud bolt

Mounting screw

Amp. Cover

LCD board

(with indicator)

Figure 6.3 Mounting and Removal of Built-in Indicator

and CPU Assembly

Loading...

Loading...