FORM 160.54-M1(503)

175

YORK INTERNATIONAL

26

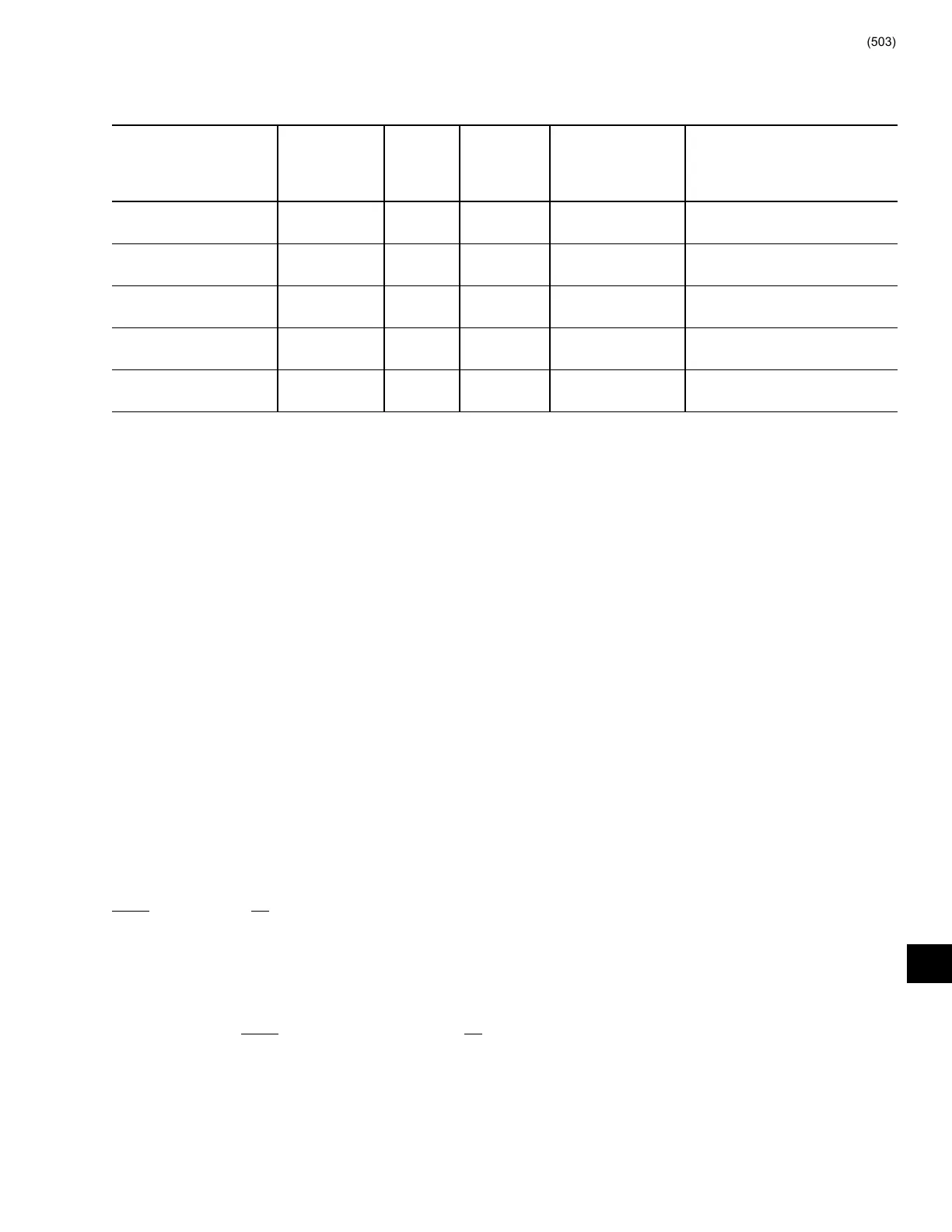

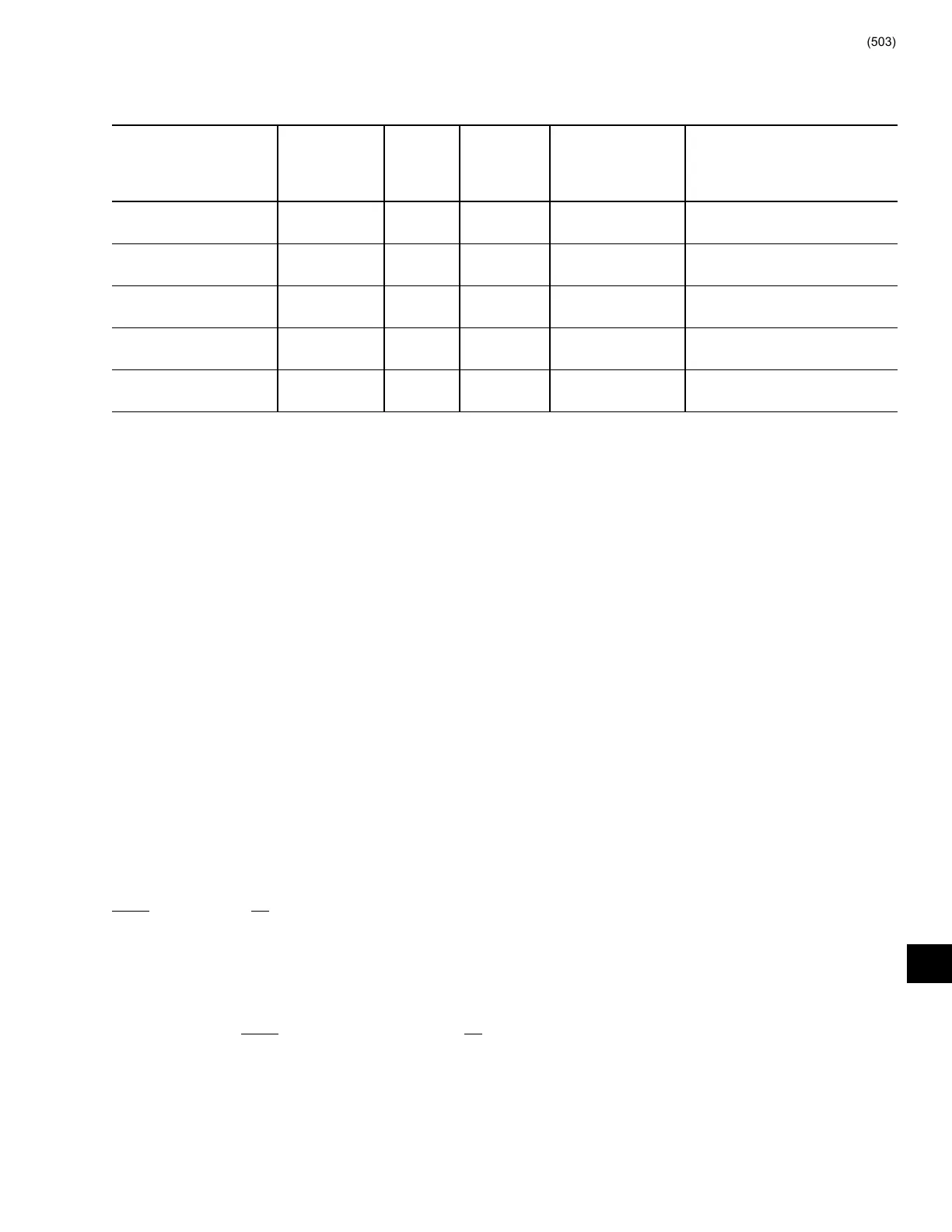

Chiller Mod –

Compressor

Proxmity

Sense

Oil

Heater

Output*

Level

Control

Period

Default

Flow

Switch

“Oil-Variable Speed

Pump Pressure Setpoint

Not Achieved” Threshold*

“Mod C, D, E –

G, H, J Compr”

Probe TB1-34 3.5 sec Paddle Type 35 PSID

“Mod E – P Compr” Limit Switch TB1-64 10.0 sec Paddle Type 25 PSID

“Mod F –

G, H Compr”

Limit Switch TB1-64 3.5 sec

Factory Mounted

Thermal Type

35 PSID

“Mod F – J Compr” Probe TB1-64 3.5 sec

Factory Mounted

Thermal Type

35 PSID

“Mod F – P Compr” Limit Switch TB1-64 10.0 sec

Factory mounted

Thermal Type

25 PSID

* Not applicable to Mod C and earlier chillers.

Factory Mounted Flow Sensors

Style "F" (and later) chillers are supplied with factory-mounted Flow Sensors on the evaporator and condenser.

These are electronic thermal-type sensors. The operating principle of the sensor is thermal conductivity. It uses the

cooling effect of a fl owing liquid to sense fl ow. The temperature of the heated sensor tip is sensed by a thermistor

located in the tip.

A second thermistor, located higher in the tip in a non-heated area, is only affected by changes in liquid temperature.

The temperatures sensed by the thermistors are compared. Flowing liquid carries heat away from the heated sensor

tip, lowering its temperature. The lower temperature differential between the two thermistors indicates the liquid is

fl owing. A higher differential indicates no fl ow. Each device operates from a 24Vac power source and has a solid

state relay output. On each sensor, one side of the solid state relay output (pin 2) is connected to the microboard

+5Vdc and the other side (pin 4) is connected to a microboard analog input.

When fl ow is sensed, the solid state relay output is turned on causing it to conduct current through the 7.5K ohm

microboard load resistor to the +5vdc. This applies >+4Vdc to the microboard input (evaporator J7-14; condenser

J7-16). When no fl ow is sensed, the solid state relay output is turned off, resulting in no conduction through the load

resistor. This applies <1Vdc to the microboard input. To determine the state of the solid state relay, fi rst confi rm that

+5vdc is present at pin 2 of the fl ow sensor. Then connect a voltmeter from Microboard J7-14 (evaporator) or J7-16

(condenser) to microboard TP1 (ground).

The power source is connected to the sensor as follows:

From

To

Sensor pin 1 TB1-162 (24Vac)

pin 3 TB6-5 (Gnd)

The sensor outputs are connected to the Microboard as follows:

Evaporator:

From To

Sensor pin 2 Microboard J7-1 (+5Vdc)

pin 4 J7-14 (input to Microboard )

Condenser:

Sensor pin 2 Microboard J7-15 (+5Vdc)

pin 4 J7-16 (input to Microboard)

Microboard Program Jumpers JP21 and JP22 must be placed in the positions 2 & 3.

SI0034 (203) - SOFTWARE ENHANCEMENTS EFFECTIVE AUGUST 2002 (CONT'D)

Loading...

Loading...