FORM 160.54-M1(503)

21

YORK INTERNATIONAL

Early vintage chillers were equipped with BIOS eprom

031-01796-001. This eprom is no longer used. It has been

su per ced ed by BIOS eprom 031-01796-002. IM POR -

TANT! Eprom 031-01796-002 is not compatible with

all versions of Flash Memory Cards. Refer to Ser vice

Re place ment para graphs in this section.

When power is applied to the OptiView Control Cen-

ter fol low ing a power failure, the Micro executes the

in struc tions in the BIOS EPROM program to initialize,

confi gure and start operation of certain Microboard

com po nents be fore the main program (stored in the

Flash Memory Card) is started. Depending upon the

ap pli ca tion, the Microboard could be equipped with an

EPROM that has either 128K, 256K or 512K ca pac i ty.

Microboard Pro gram Jumper JP38 must be po si tioned

according to the actual EPROM installed. Refer to

Ta ble 1 (Pro gram Jump ers). There are 5 steps to the

boot-up pro cess. Dur ing the boot-up process, there is

a visual in di ca tion as each step is performed, followed

by a Pass/Fail sta tus of the step. On the Microboard, a

green LED (CR17 - Pass) fl ash es to in di cate the step was

suc cess ful. If a step is un suc cess ful, a red LED (CR18

- Fail) fl ashes and the Boot-up pro cess ter mi nates. The

ex e cu tion and Pass/Fail sta tus of steps 3 through 5 are

displayed on a white Key pad Dis play Screen as they are

performed. This white dis play screen also lists the BIOS

EPROM Ver sion. The steps of the Boot-up pro cess are

as fol lows. Also, be low is listed the LED ac tiv i ty as-

sociated with each step.

BOOT-UP STEP AND DESCRIPTION

1. First initiate table complete.

Registers in the Micro are confi gured to allow it to per-

form basic mem o ry read/write func tions.

2. FPGA confi guration.

The Field Pro gram ma ble Gate Array (FPGA) is con-

fi g ured to process Digital Inputs and Out puts.

3. Mini-card signature test.

A location in the Flash Memory Card that contains a code

iden ti fy ing the Man u fac tur er is compared to oth er lo ca -

tions that contain the man u fac tur er’s name. If these val ues

are the same, it is pass. If they are different, it is fail.

4. Mini-card checksum.

The Flash Memory Card checksum is calculated and

com pared to the checksum value that is stored in the

Card at the time the Card was initially programmed at

the YORK fac to ry. If both val ues are the same, it is

con sid ered pass. If the cal cu lat ed value is different than

the stored value, it is considered fail.

5. BRAM quick test.

Test data is written to and then read from several mem o ry

locations to ver i fy BRAM operation.

LED INDICATORS

When power is applied to the OptiView Control Cen ter,

both the red (CR18 - Fail) and green (CR17 - Pass) LEDs

si mul ta neous ly il lu mi nate for 1 sec ond, then the Boot-

up pro cess begins in the fol low ing sequence. When all

steps have been com plet ed, both LED’s illuminate and

remain il lu mi nat ed.

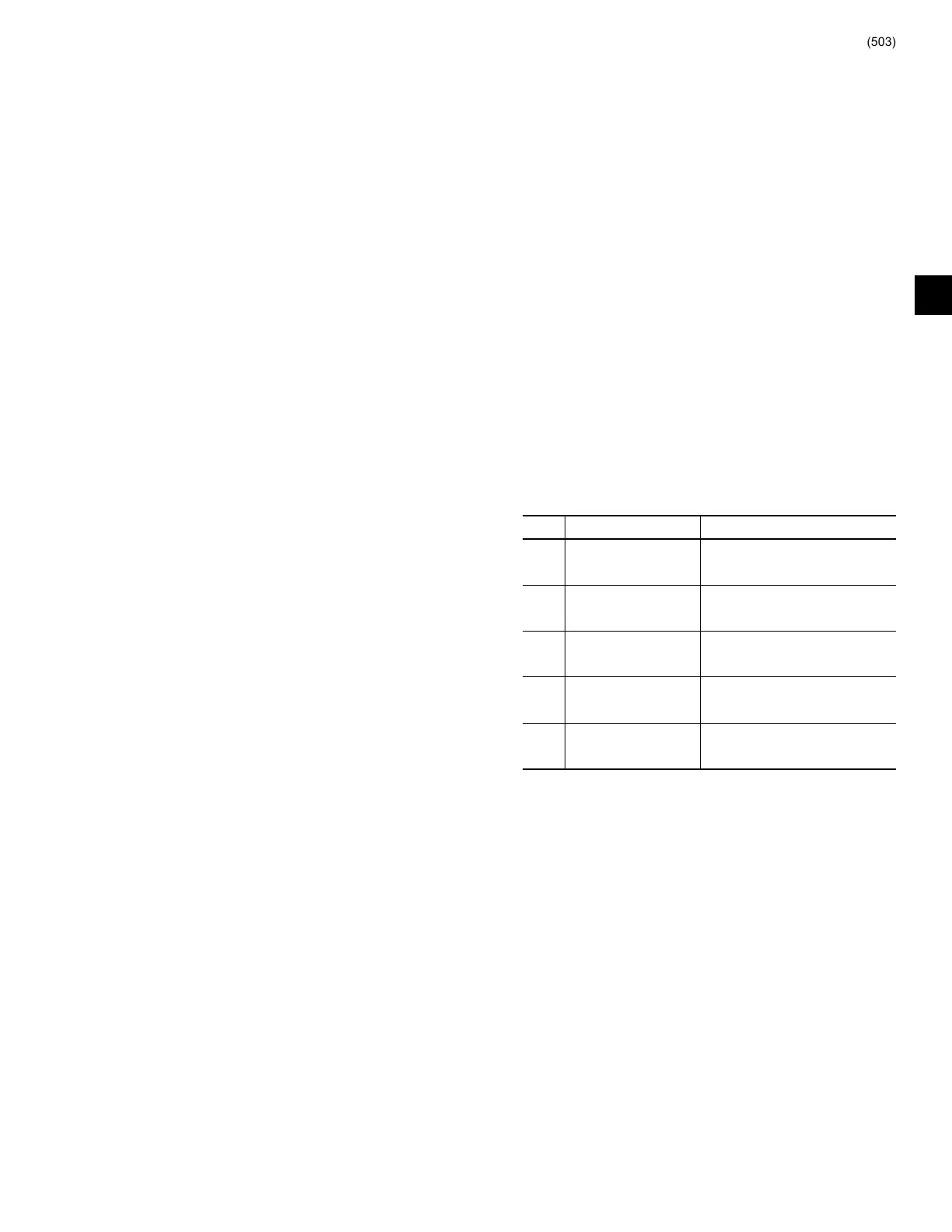

STEP PASS FAIL

1 Green on, Red off

Watchdog will

initiate a re-boot.

2 Green fl ash once

Boot-up pro cess halts.

One red fl ash repeating

3 Green fl ash once

Boot-up pro cess halts.

Two red fl ashes repeating

4 Green fl ash once

Boot-up pro cess halts.

Three red fl ashes repeating

5 Green fl ash once

Boot-up pro cess halts.

Four red fl ashes repeating

The BRAM (battery backed random access mem o ry) is

a memory device that contains a battery that pre serves

the data during power failures. It is a re place able part.

Refer to YORK Renewal Parts List Form 160.54-RP1.

It is located in socket location U52. The Micro stores

the setpoints programmed by the Op er a tor or Service

Tech ni cian, History Data and other data that requires

pres er va tion, in this device. Also, the day of week, time

of day and calendar date time-keeping are done here.

The FPGA (fi eld programmable gate array) is a single

chip consisting of generic circuits that can be con fi g ured

to perform a specifi c task. In this OptiView Control Cen-

ter, it is used to control the Digital Outputs. As part of

the pow er-up initialization sequence, each time control

pow er is ap plied to the OptiView Control Center, the Mi-

3

Loading...

Loading...