50 JOHNSON CONTROLS

FORM 150.63-EG4 (1012)

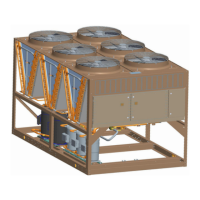

coils from incidental damage,visually screen

internal components, and prevent unauthorized

access to internal components.

4. Louvered/Wire Panels: Louvered steel panels

on external condenser coil faces, painted as per

remainder of unit cabinet. Heavy gauge, welded

wire-mesh, coated to resist corrosion, around

base of machine to restrict unauthorized access.

J. Service Isolation valves: Service suction and dis-

charge (ball type) isolation valves are added to unit

per system. This option also includes a system high

pressure relief valve in compliance with ASHRAE15.

(Factory-mounted.)

K. Hot Gas By-Pass: Permits continuous, stable opera-

tion at capacities below the minimum step of unload-

ing to as low as 5% capacity (depending on both the

unit & operating conditions) by introducing an articial

load. Hot gas by-pass is installed on only refrigerant

system #1 on two circuited units. (Factory-mounted.)

L. Microprocessor Membrane Keypad Graphics on in

lieu of Standard English:

1. French language.

2. German language.

3. Spanish language.

4. Italian language.

M. Chicago Code Relief Valves to meet Chicago Code

requirements.

N. Building Automation System (EMS) Reset Interface:

Condensing Unit to accept 4 to 20mA, 0 to 10 VDC,

input to reset the discharge air temperature.

O. Sound Reduction (Factory Mounted):

1. Low speed, reduced noise fans

2. Compressor Acoustic Sound Blankets

P. Vibration Isolation (Field Mounted):

1. Neoprene Pad Isolators.

2. 1 Inch Deection Spring Isolators: Level adjust-

able, spring and cage type isolators for mounting

under the unit base rails.

3. 2 Inch Deection Isolators: Level adjustable, re-

strained mounts in rugged welded steel housing

with vertical and horizontal limit stops. Housings

shall be designed to withstand a minimum 1.0g

accelerated force in all directions to 2 inches.

PART 3 - EXECUTION

3.01 INSTALLATION

A. General: Rig and Install in full accordance with

Manufacturers requirements, Project drawings, and

Contract documents.

B. Location: Locate condensing unit as indicated on

drawings, including cleaning and service mainte-

nance clearance per Manufacturer instructions. Ad-

just and level condensing unit on support structure.

C. Components: Installing Contractor shall provide and

install all auxiliary devices and accessories for fully

operational condensing unit.

D. Electrical: Coordinate electrical requirements and

connections for all power feeds with Electrical Con-

tractor (Division 16).

E. Controls: Coordinate all control requirements and

connections with Controls Contractor.

F. Finish: Installing Contractor shall paint damaged and

abraded factory nish with touch-up paint matching

factory nish.

Guide Specications - continued

Loading...

Loading...