FORM 150.63-EG4 (1012)

5JOHNSON CONTROLS

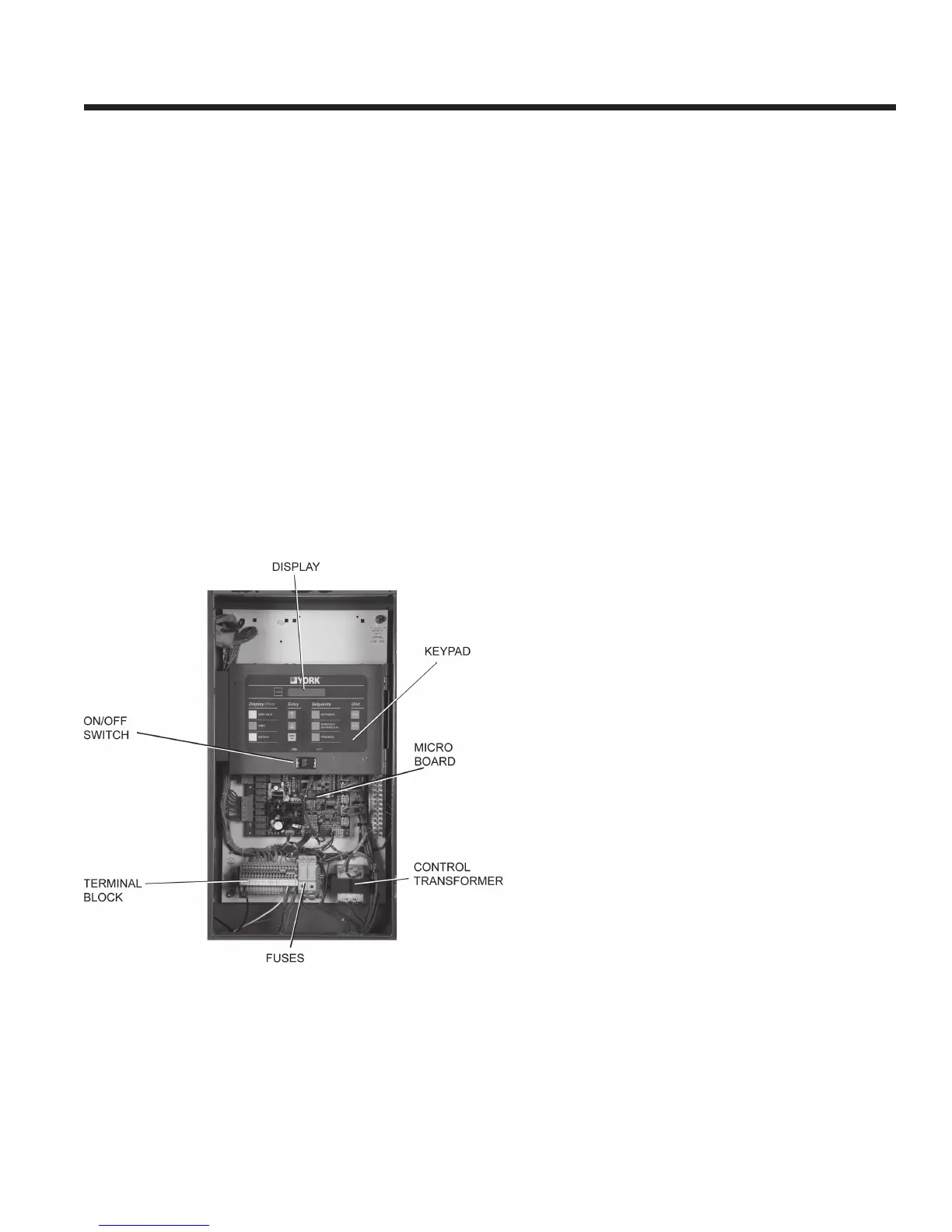

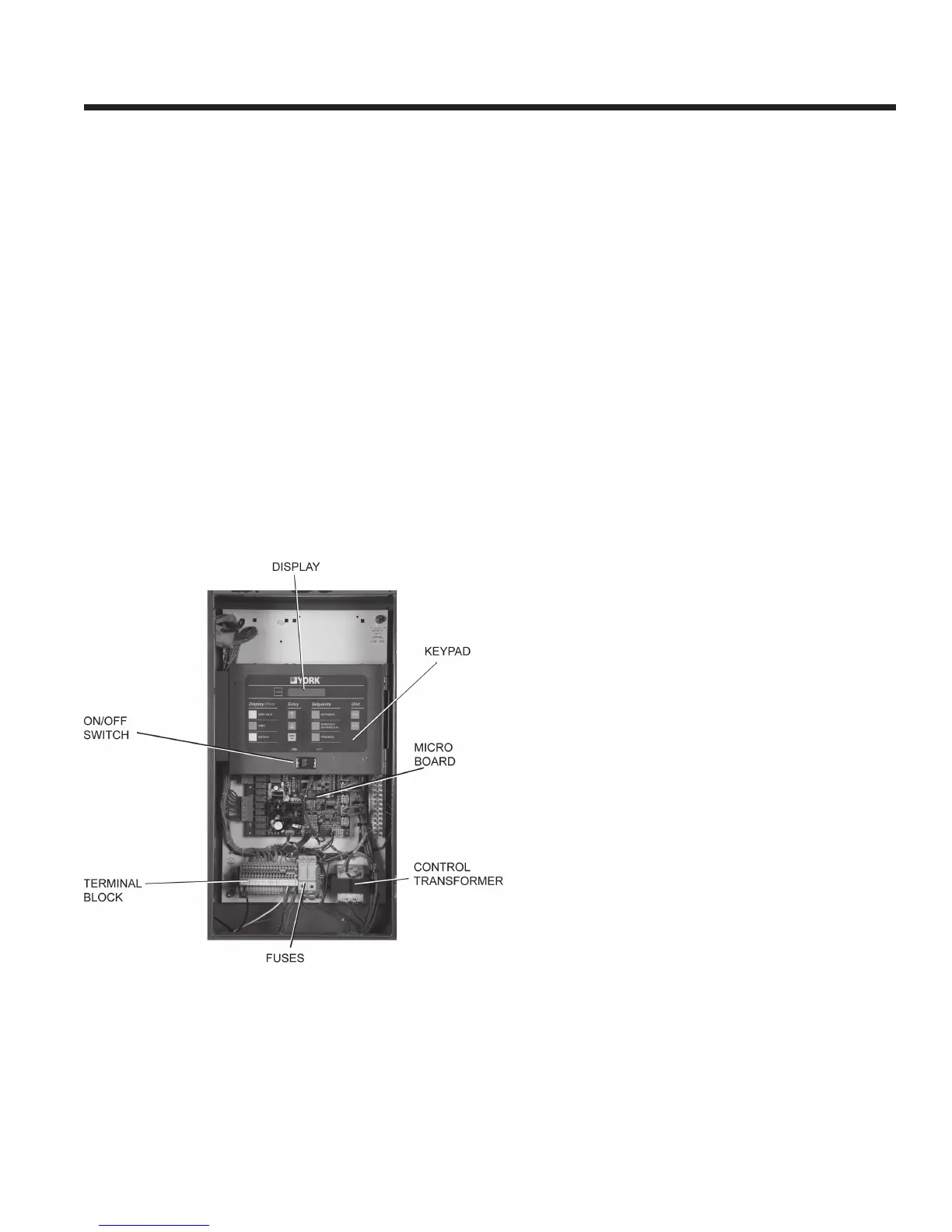

Microcomputer Control Center

All controls are contained in a NEMA 3R cabinet with

hinged and gasketed outer door and includes:

Liquid Crystal Display with Light Emitting Diode backlight-

ing for outdoor viewing:

• Two display lines

• Twenty characters per line

Color coded 12-button non-tactile keypad with sections

for:

DISPLAY/PRINT of typical information:

• Suction temperatures (optional)

• Ambient temperature

• System pressures (each circuit)

• Operating hours and starts (each compressor)

• Print calls up to the liquid crystal display:

• Operating data for the systems

• History of fault shutdown data for up to the last

six fault shutdown conditions

• An RS-232 port, in conjunction with this press-to-print

button, is provided to permit the capability of hard

copy print-outs via a separate printer (by others).

ENTRY section to:

• ENTER setpoints or modify system values SET-

POINTS updating can be performed to:

• Suction pressure setting

• Suction pressure control zone

• Remote reset temperature range

• Set daily schedule/holiday for start/stop

• Manual override for servicing

• Low and high ambient cutouts

• Number of compressors

• Low suction pressure cutout

• High discharge pressure cutout

• Anti-recycle timer (compressor start cycle time)

• Anti-coincident timer (delay compressor starts)

UNIT section to:

• Set clock

• Set options

• Set unit option

Set unit control for Discharge Air Temperature Control or

for Suction Pressure Control (requires Suction Pres sure

Transducers – standard.

UNIT ON/OFF switch

The microprocessor control center is capable of display-

ing the following:

• Suction temperatures (optional)

• Low ambient temperature cutout setting

• Outdoor air temperature

• English or Metric data

• Suction pressure cutout setting

• Each system suction pressure

• System discharge pressure

FIG.1 – CONTROL PANEL COMPONENTS

Loading...

Loading...