SR24 - 923-03509 ii CS - SAFETY

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

X-RADIATION

To prevent possible exposure to radiation caused by excessive

CRT Anode voltage, the CS Chassis incorporates a “High Volt-

age Shutdown” circuit. This circuit senses the level of flyback

pulse from the “Flyback Transformer” representative of the

actual high voltage on the CRT anode. When this level ex-

ceeds a predetermined voltage, the circuit shuts down the

horizontal drive, preventing further generation of anode volt-

age. In this condition, the horizontal drive is “latched” off for

about 5 seconds, after which, restart is attempted.

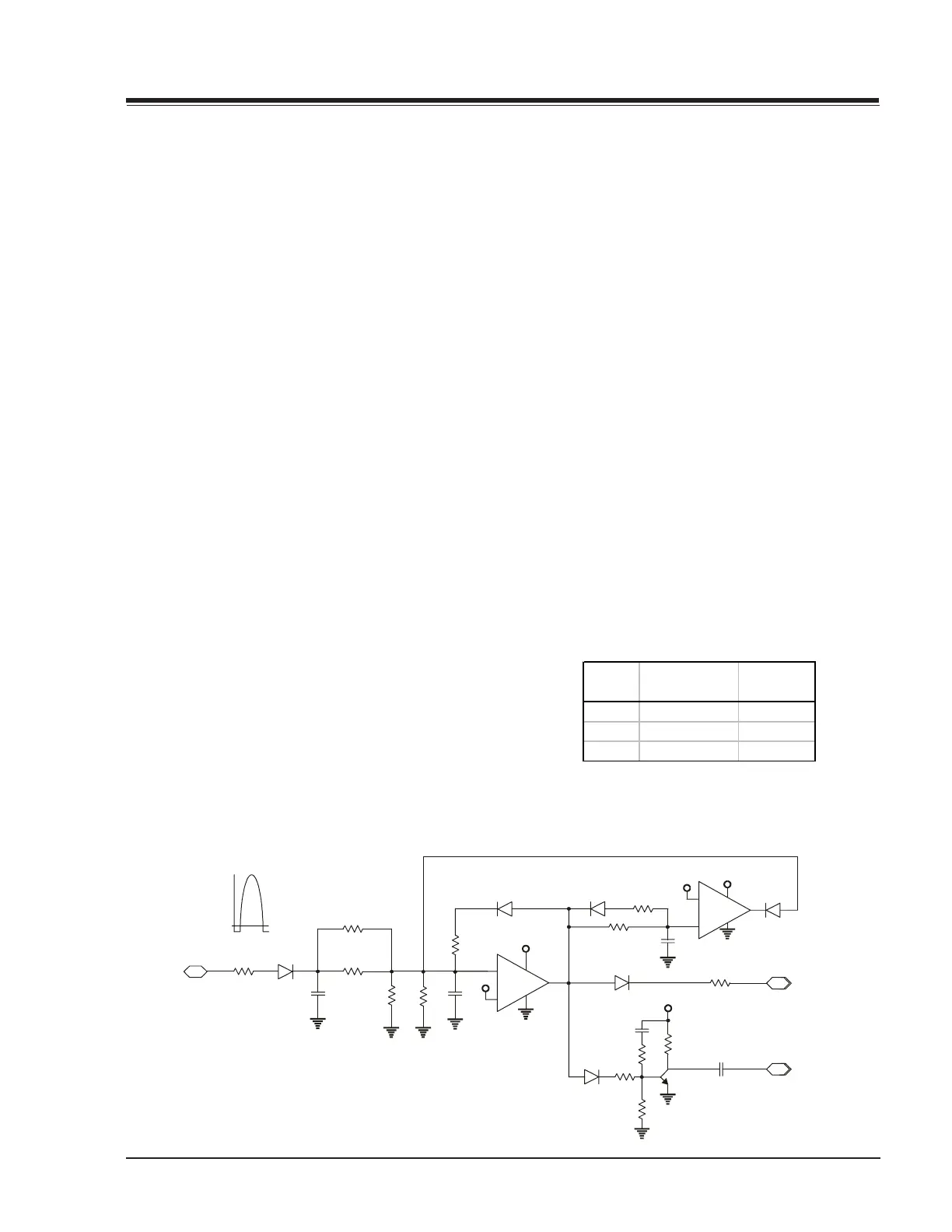

SHUTDOWN CIRCUIT OPERATION

The flyback pulse voltage from Pin 6 of TX3201 (Flyback Trans-

former) is peak detected (rectified) by the action of diode

D3206 and capacitor C3214. This forms a DC voltage appear-

ing on C3214 representative of the CRT anode voltage (HV)

produced by T3201. This voltage is divided down by precision

resistors RX3214, RX3215, RX3216 & RX3217. This lower volt-

age, appear on the non-inverted input (pin 5) of IC3201.

If the CRT anode voltage become excessive, pin 5 of IC3201

will be higher than inverted input of pin 6. This will cause the

output of pin 7 to rise to approximately 15 volts. This signal

(SD_DRV) is sent to the base of Q4000 causing Horizontal

Drive to be disabled and latched, which causes the HV to

shutdown. In about 5 seconds, the shutdown circuit resets

(Pins 8, 9 & 14 of IC2900), the Horizontal Drive and HV will be

reestablished. The circuit formed by Q2907, C2913, C2916,

D2908, R2923, R2935, R2936, and R2937 disables the HV

compensation output (Q2902-b signal) during turn on and shut-

down conditions (transients).

CRT ANODE HIGH VOLTAGE MEASUREMENT PROCEDURE

Each CRT screen has it’s own safe operating Anode Voltage

and shutdown voltage. Critical Safety components (designated

with an ‘X’ in the component designator) are designed to

operate the CRT at a safe operating Anode voltage and pro-

vide proper shutdown thresholds. If replacement of any of

these components is deemed necessary, it is important to use

original type Zenith replacement components.

After a replacement is made, confirm proper Anode voltage

using the following procedure.

Measurement of the CRT Anode voltage must be performed

with no visible raster on the screen and operating at nominal

horizontal scanning frequency 15.734 or 37.9 Khz (TV or SVGA

signal).

After discharging the CRT, connect a high impedance high

voltage meter to the CRT anode. Turn the television ‘On’ and

confirm good signal is being displayed. Reduce Brightness

and Contrast settings until the picture is well extinguished.

Observe the Anode voltage meter reading and compare with

the table below for the proper CRT screen size. If the voltage

reading is higher than the maximum, verify circuit component

values and proper operation.

HV SHUTDOWN MEASUREMENT PROCEDURE

1. Adjust the beam current to 0 mA in NTSC mode.

2. Apply a variable DC voltage to pin 10 of the PTD1 connec-

tor, from 20 to 0 Vdc, starting at 20 Vdc.

3. Slowly decrease supply towards zero.

4. Remove DC voltage from pin 10 of PTD1.

5. After approximately 5 seconds, verify that the HV is rees-

tablished (High Voltage Reset).

SHUTDOWN SAFETY CIRCUIT

IN

RX3213

From Pin 6, T3201

D3206

C3214

RX3216

RX3217

C3215

RX3214

RX3215

R3221

D3207

+15V

+5V

V-

V+

+

-

IC3201

R4015

OUT

To Base of Q2902

SHUTDOWN

(SD_DRV)

Flyback Pulse

+15V

V-

V+

+

-

IC2900

8

+15V

OUT

C2913

R2923

R2935

C2916

Q2907

R2936

R2937

D2908

D4002

C2917

R2943

R2944

D2909

D2910

To Base of Q4000

HV COMPENSATIO

DISABLE

+5V

9

14

Screen

Size

HV Nominal

Level (kV)

HV Max

Level (kV)

27" 27 29

32" 30 31.5

36" 30 31.5

Loading...

Loading...